Semiconductor hydrogen production catalyst based on compounding of titanium dioxide and molybdenum sulfide, and preparation method and application thereof

A technology of titanium dioxide and molybdenum sulfide, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve problems such as expensive price and limited application scope, achieve low cost, simple synthesis method, and solve energy crisis. Potentially applicable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

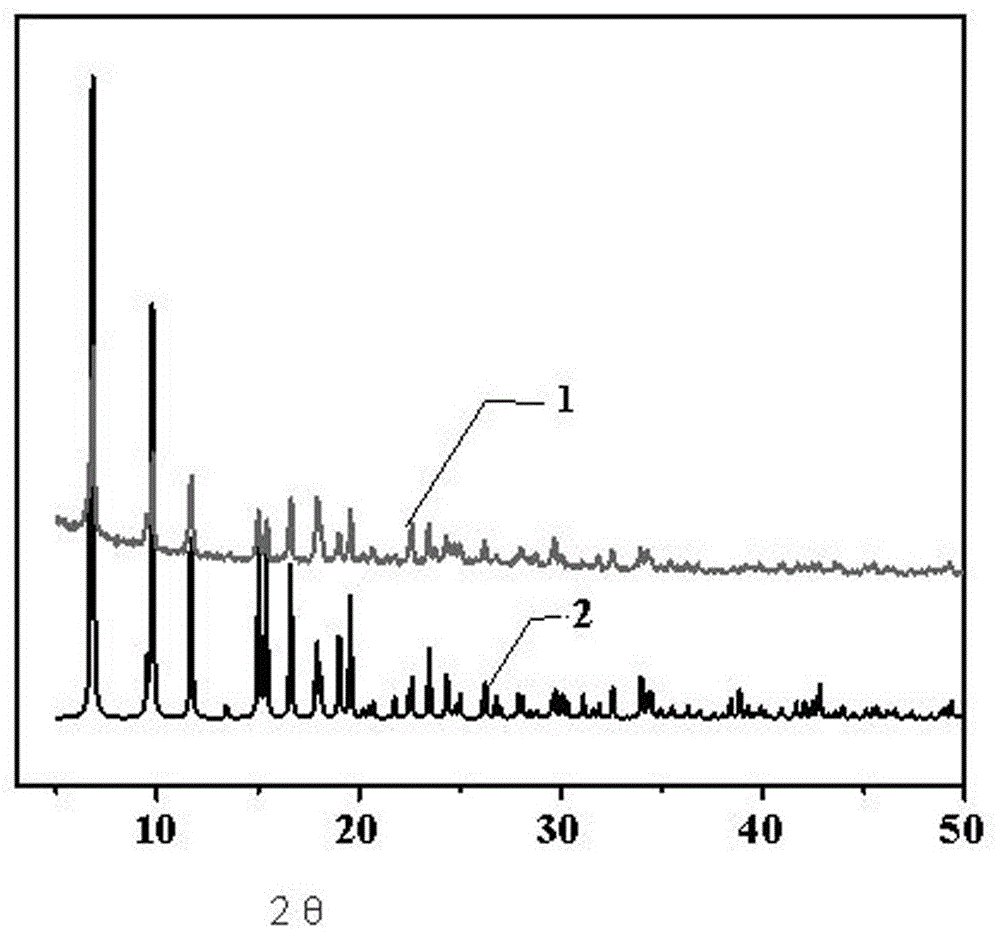

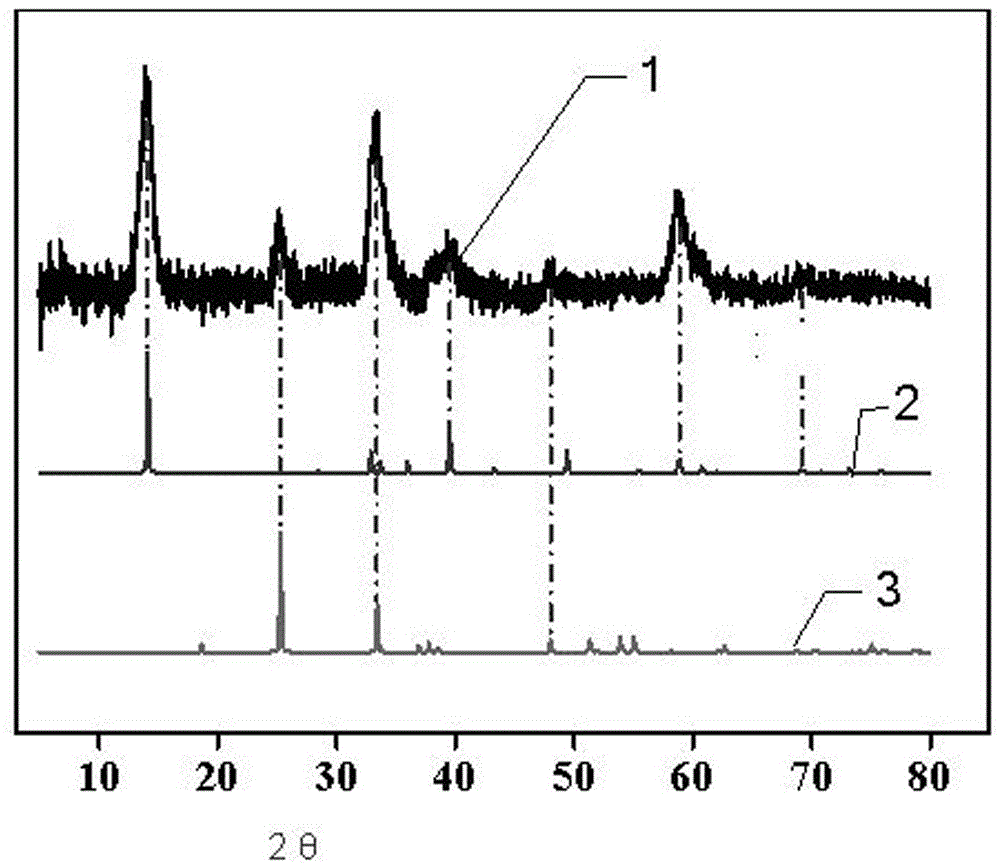

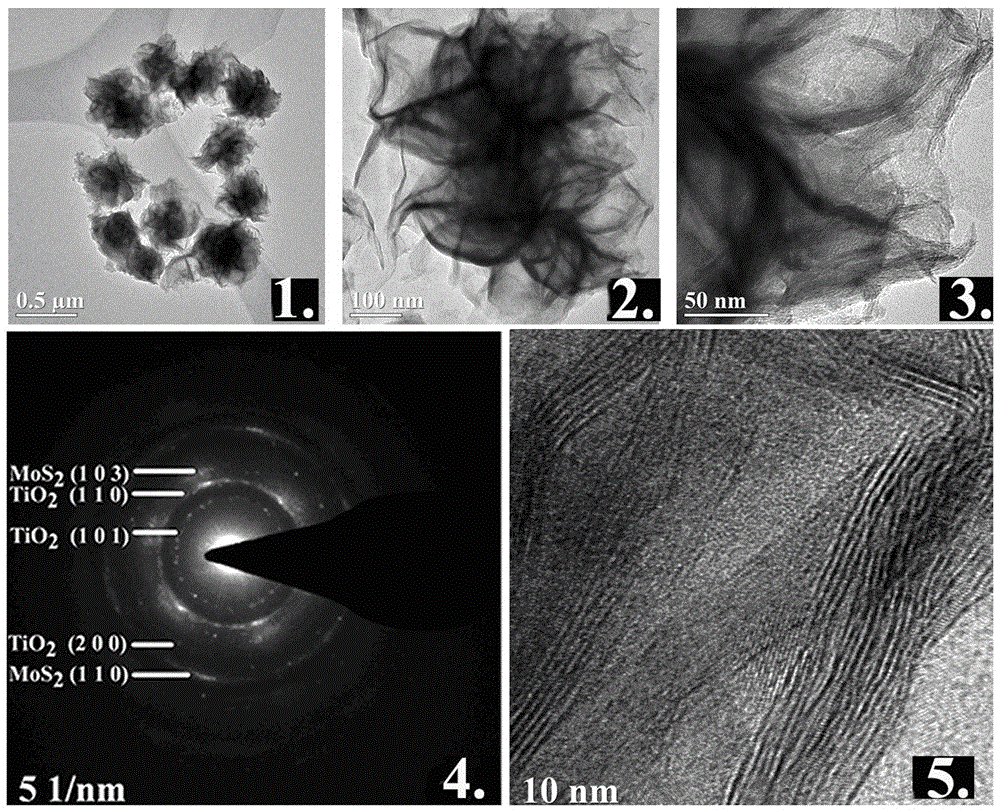

[0027] Example 1: Synthesis of a semiconductor hydrogen production catalyst based on the composite of titanium dioxide and molybdenum sulfide

[0028] (1) Dissolve 2-aminoterephthalic acid and tetrabutyl titanate in a mixed solvent of anhydrous N,N-dimethylformamide and absolute ethanol, seal them in a reaction kettle, and At 120°C for three days at a constant temperature, the natural condition dropped to room temperature to obtain a suspension. The molar ratio of 2-aminoterephthalic acid to tetrabutyl titanate is 8:1. The volume ratio of N,N-dimethylformamide and absolute ethanol is 9:1.

[0029] (2) The suspension obtained in (1) was centrifuged, washed three times with ethanol and pure water respectively, accompanied by ultrasonic treatment, and finally centrifuged to obtain a yellow solid. Dry at 75°C for 12 hours, take out and grind to obtain a yellow solid powder, which is the MOF precursor NH 2 -MIL-125.

[0030] (3) The precursor NH 2 -MIL-125 (0.08mmol), thiourea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com