Method for catalyzing hydrogen production from formic acid

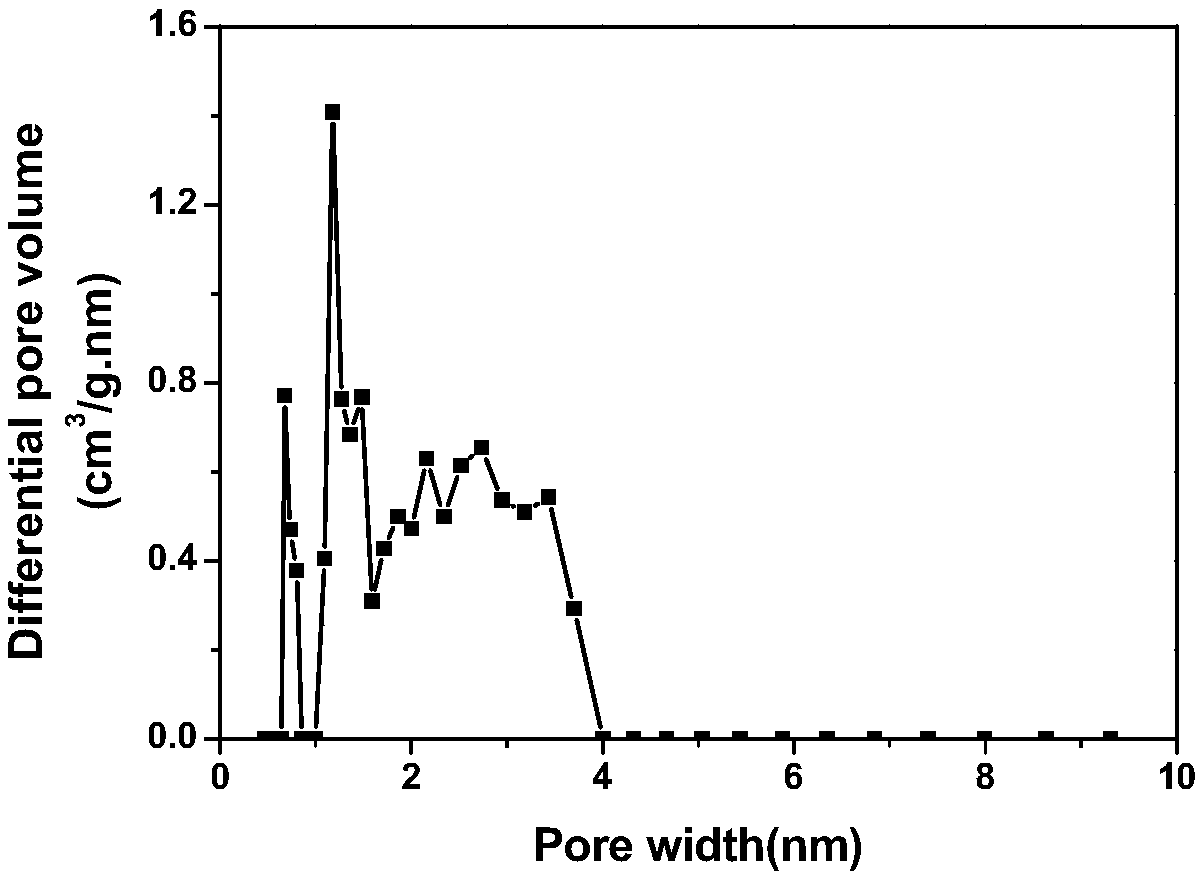

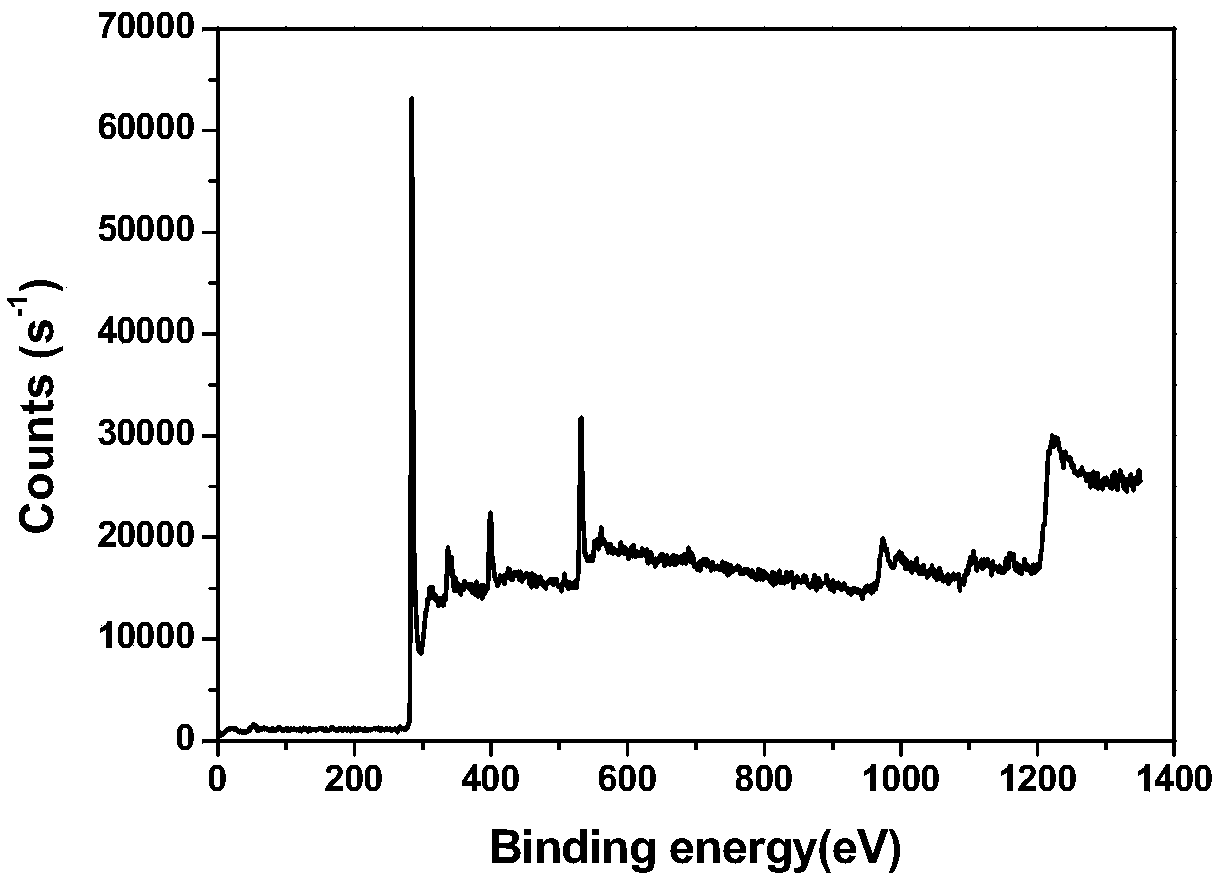

A formic acid and catalyst technology, which is applied in the field of hydrogen production from formic acid catalyzed by noble metal Pd-supported catalysts, can solve the problems of low hydrogen production activity and achieve high catalytic efficiency, good economic and environmental benefits, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Synthesize CTF

[0034] 1) 1.596g of anhydrous zinc chloride (stored in a glove box) and 0.3g of 1,4-terephthalonitrile were ground in a glove box, and the resulting powder was transferred to a quartz tube;

[0035] 2) Use a vacuum pump to vacuum to a degree of 10 -2 Pa, after sealing, heat to 300°C for 60 hours, continue heating to 450°C for 5 hours;

[0036] 3) The obtained black block material is washed repeatedly with distilled water and 1.0M HCl solution after crushing, for removing residual zinc chloride;

[0037] 4) Wash the obtained black powder with distilled water and tetrahydrofuran, and dry it under vacuum at 150°C overnight to obtain CTF-450.

[0038] Step 2: Loading precious metal Pd

[0039] 1) Add 0.15g of CTF-450 to 10ml of deionized water, then add appropriate amount of PdCl 2 solution, stirred for 3 hours and then washed with 1.0M Na 2 CO 3Adjust the pH to 10.5 and continue stirring for 2 hours;

[0040] 2) Wash the material with deioni...

Embodiment 2

[0049] Step 1: Synthesize CTF

[0050] 1) 0.9576g of anhydrous zinc chloride (stored in a glove box) and 0.3g of 1,4-terephthalonitrile were ground in a glove box, and the resulting powder was transferred to a quartz tube;

[0051] 2) Use a vacuum pump to vacuum to a degree of 10 -2 Pa, after sealing, heat to 300°C for 60 hours, continue heating to 550°C for 6 hours;

[0052] 3) The obtained black block material is washed repeatedly with distilled water and 1.0M HCl solution after crushing, for removing residual zinc chloride;

[0053] 4) Wash the obtained black powder with distilled water and tetrahydrofuran, and dry it under vacuum at 150°C overnight to obtain CTF-550.

[0054] Step 2: Loading precious metal Pd

[0055] 1) Add 0.15g of CTF-550 to 10ml of deionized water, then add appropriate amount of PdCl 2 solution, after stirring for 3 hours, adjust the pH to 11, and continue stirring for 2 hours;

[0056] 2) Wash the material with deionized water until neutral, and ...

Embodiment 3

[0061] Step 1: Synthesize CTF

[0062] 1) 0.319g of anhydrous zinc chloride (stored in a glove box) and 0.3g of 1,4-terephthalonitrile were ground in a glove box, and the resulting powder was transferred to a quartz tube;

[0063] 2) Use a vacuum pump to vacuum to a degree of 10 -2 Pa, after sealing, heat to 300°C for 60 hours, continue heating to 650°C for 4 hours;

[0064] 3) The obtained black block material is washed repeatedly with distilled water and 1.0M HCl solution after crushing, for removing residual zinc chloride;

[0065] 4) Wash the obtained black powder with distilled water and tetrahydrofuran, and dry it under vacuum at 150°C overnight to obtain CTF-650.

[0066] Step 2: Loading precious metal Pd

[0067] 1) Add 0.15g of CTF-650 to 10ml of deionized water, then add appropriate amount of PdCl 2 solution, after stirring for 3 hours, adjust the pH to 9, and continue stirring for 2 hours;

[0068] 2) Wash the material with deionized water until neutral, and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com