Preparation method of graphene

A graphene and fluorinated graphite technology, applied in the field of nanomaterial preparation, can solve the problems of low atomic ratio of C and O in graphene, and achieve the effects of large sheet area, easy mass production, and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

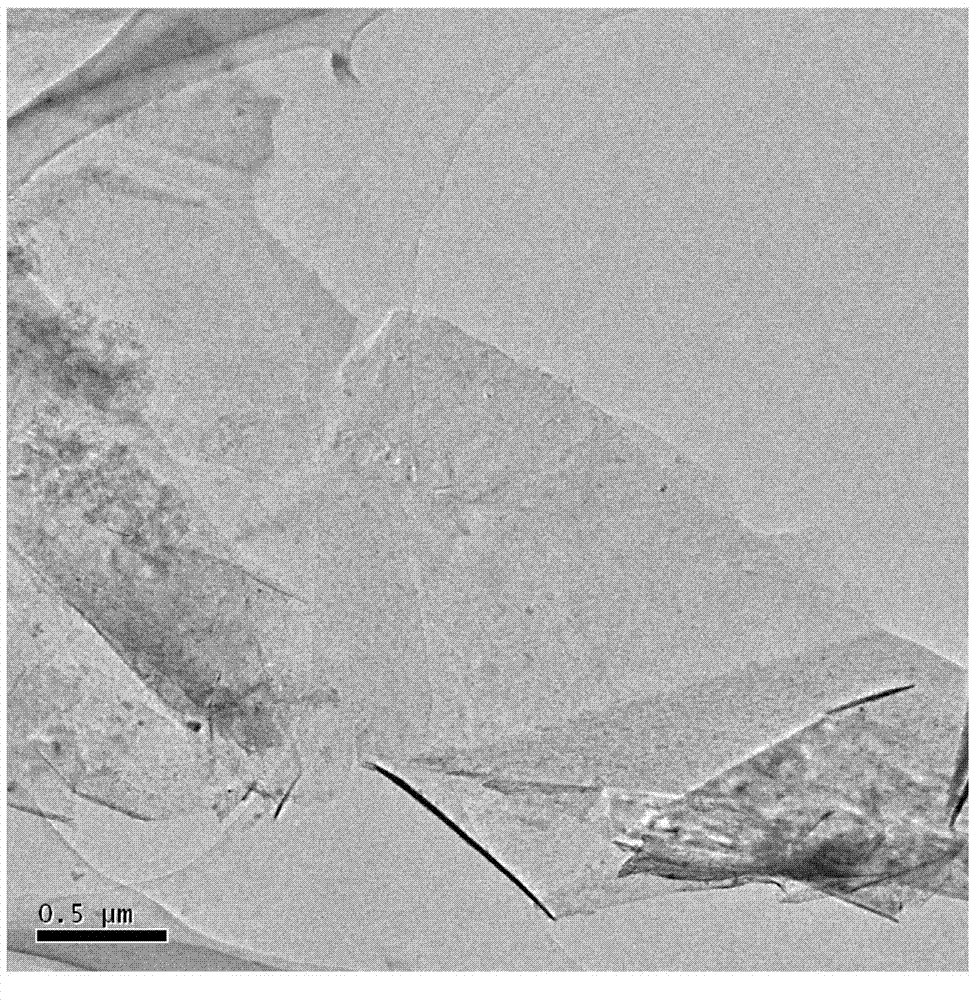

Image

Examples

Embodiment 1

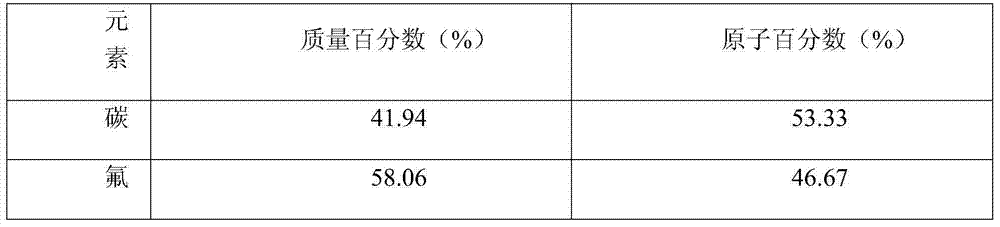

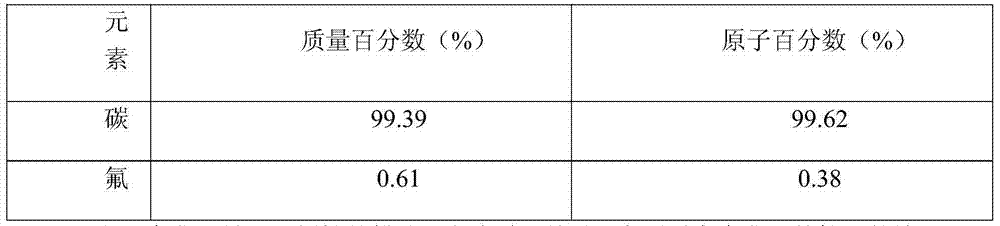

[0017] Mix sodium chloride, potassium chloride, and zinc chloride in a mass ratio of 1:1:3, heat at 250°C for 30 minutes to melt, then mix 100mg of graphite fluoride with 5g of the above molten salt, and heat at 300°C Heat for 10 hours to carry out thermal intercalation reaction. After the heating time is over, add the above-mentioned intercalation complex to 200mL N-methylpyrrolidone, and then ultrasonicate the resulting suspension at 200W power for 12 hours. After the ultrasonic time is over, the ultrasonicated suspension Centrifuge at a speed of 2000r / min for 20min to remove the solid in the lower layer, suction filter the obtained solution, wash with deionized water three times, and then dry the obtained filter cake at 60°C to obtain a graphene material.

Embodiment 2

[0019] Mix sodium chloride, potassium chloride, and zinc chloride in a mass ratio of 1:1:3, heat at 250°C for 30 minutes to melt, then mix 200mg of graphite fluoride with 5g of the above molten salt, and heat at 280°C Heated for 12 hours to perform thermal intercalation reaction. After the heating time was over, the above intercalation complex was added to 200 mL of dimethylformamide, and then the resulting suspension was ultrasonicated at 200 W for 10 hours. After the ultrasonic time was over, the ultrasonic suspension was The solution was centrifuged at a speed of 1000r / min for 20min to remove the solid in the lower layer, the obtained solution was suction-filtered, washed three times with deionized water, and then the obtained filter cake was dried at 60°C to obtain a graphene material.

Embodiment 3

[0021] Mix sodium chloride, potassium chloride, and zinc chloride in a mass ratio of 1:1:3, heat at 250°C for 30 minutes to melt, then mix 100mg of graphite fluoride with 5g of the above molten salt, and heat at 200°C Heated for 12 hours to carry out thermal intercalation reaction. After the heating time was over, the above intercalation complex was added to 200 mL of isopropanol, and then the resulting suspension was ultrasonicated for 12 hours at a power of 200 W. After the ultrasonic time was over, the ultrasonicated suspension was placed in Centrifuge at a speed of 3000r / min for 15min to remove the solids in the lower layer, suction filter the obtained solution, wash with deionized water three times, and then dry the obtained filter cake at 60°C to obtain a graphene material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com