Synthesis method for azilsartan medoxomil or salt thereof, intermediate of azilsartan medoxomil or salt thereof and synthesis method for intermediate

A technology for azilsartan medoxomil and intermediates, applied in the direction of organic chemistry, etc., can solve the problems of low yield and many by-products in the synthesis of azilsartan medoxomil, and achieve the effect of easy purification of finished products and increased reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

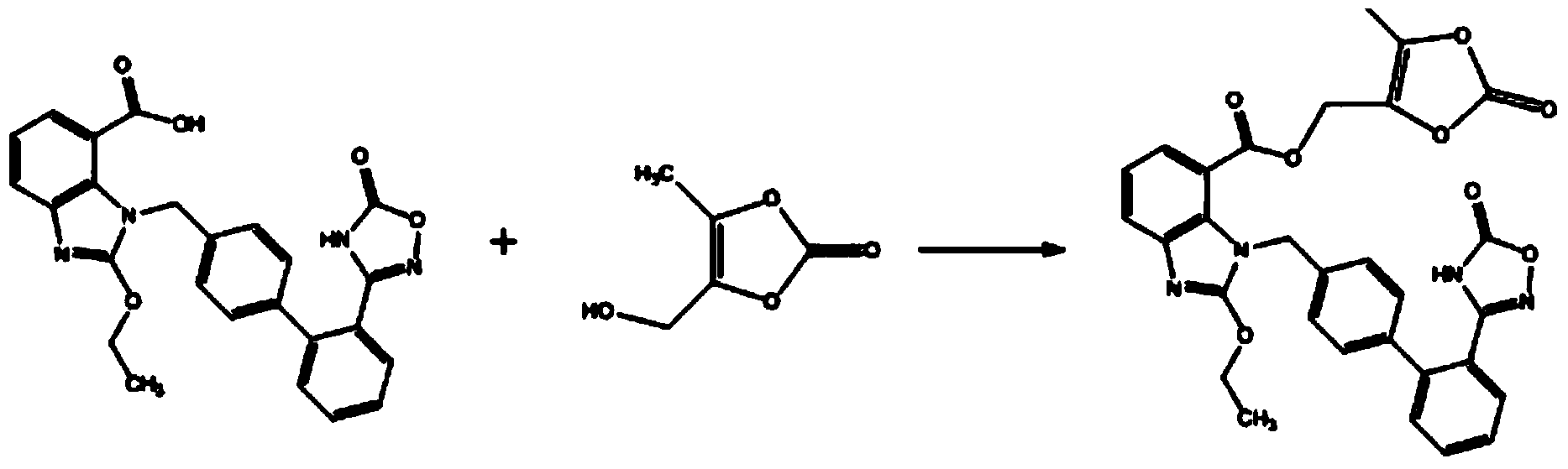

Method used

Image

Examples

Embodiment 1

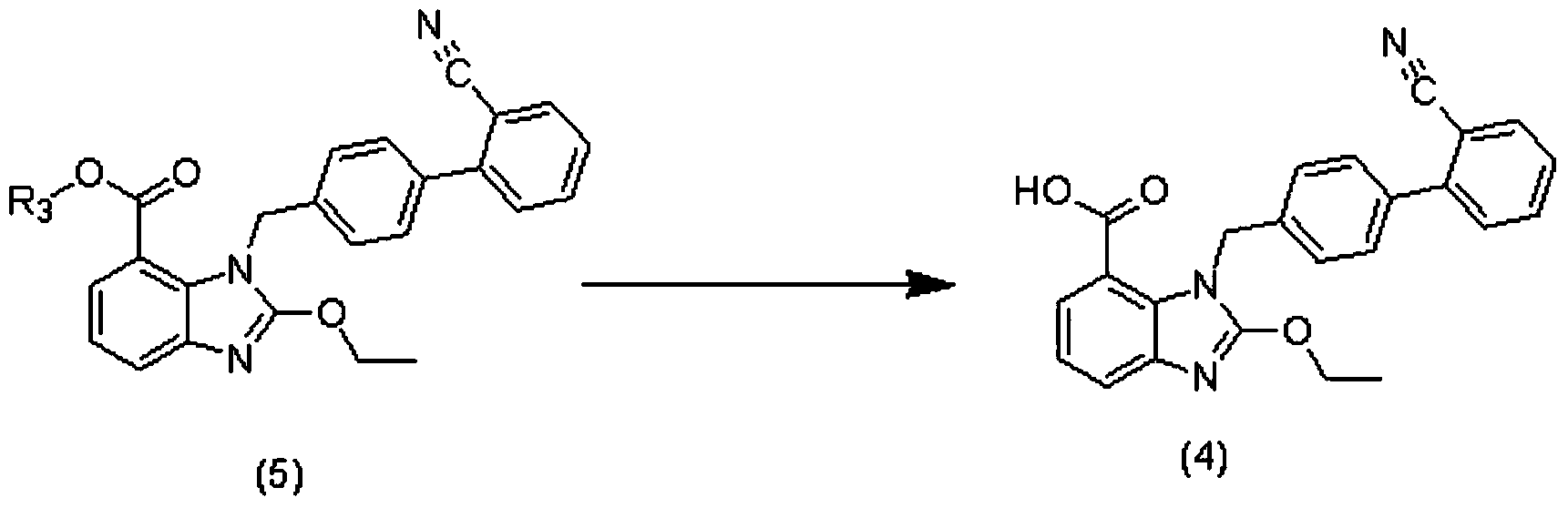

[0048] 1), the preparation of the compound of formula (4)

[0049]

[0050] Add 159g of methanol and 24.2g of the methyl ester compound of formula (5) into a 500mL reactor, stir for 10 minutes, add 10% sodium hydroxide solution dropwise, and heat to reflux for 2 hours. Cool down to room temperature, add 500g of water, adjust the pH value to neutral with 2N hydrochloric acid, precipitate a solid, filter, wash with water, and dry to obtain the compound of formula (4), with a yield of 95.6%.

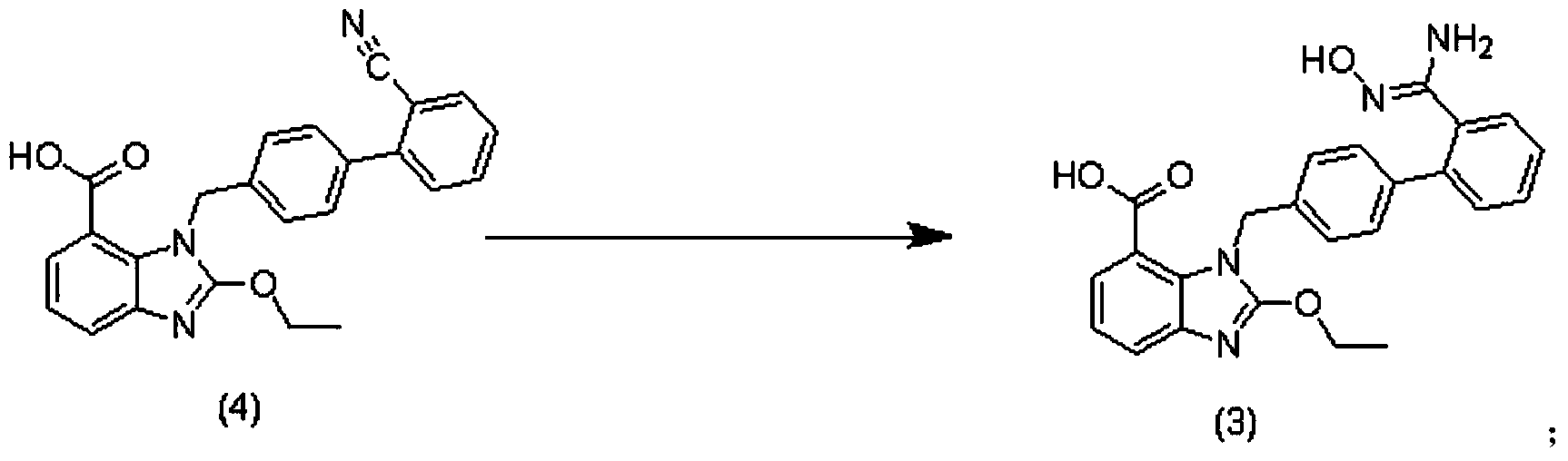

[0051] 2) Preparation of the compound of formula (3)

[0052]

[0053] Add 48.8g of hydroxylammonium hydrochloride and 81.6g of sodium bicarbonate to 400mL of dimethyl sulfoxide, stir at room temperature for 1 hour, add 16.1g of the compound of formula (4), heat to 90°C for 24 hours, add 800ml of water, and adjust the pH value with 2N hydrochloric acid To neutrality, a solid was precipitated, filtered, washed with water, and dried to obtain the compound of formula (3), with a yield o...

Embodiment 2

[0064] 1) Preparation of the compound of formula (4)

[0065]

[0066] Add 159g of methanol and 24.2g of the methyl ester compound of formula (5) into a 500mL reactor, stir for 10 minutes, add 10% sodium hydroxide solution dropwise, and heat to reflux for 2 hours. Cool down to room temperature, add 500g of water, adjust the pH value to neutral with 2N hydrochloric acid, precipitate a solid, filter, wash with water, and dry to obtain the compound of formula (4), with a yield of 95.6%.

[0067] 2) Preparation of the compound of formula (3')

[0068]

[0069] Add 16.2 g of the compound of formula (4) and 8.8 g of potassium carbonate into 200 mL of acetone, slowly add 6.0 g of the compound of formula (6) dropwise, and stir the reaction at room temperature for 10 hours after the addition. The insoluble matter was removed by filtration, and the mother liquor was concentrated to dryness to obtain the compound of formula (3'), with a yield of 86.2%.

[0070] H NMR (300MHz, DMS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com