A kind of production technology of VC ethyl ether

A production process and technology of ethyl ether, applied in the field of production technology of Vc ethyl ether, can solve the problems of inability to ensure the purity of Vc ethyl ether finished product, high equipment and control costs, and many times of material transfer, etc. The effect of waste treatment costs, reduced equipment and control costs, and reduced process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

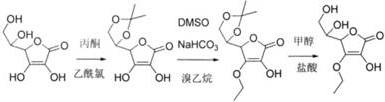

[0034] A production process of Vc ethyl ether, adopting the following synthetic route: taking vitamin C as a starting material, through acetonylidene protection, etherification and hydrolysis deprotection, to obtain Vc ethyl ether; the production process specifically includes the following steps :

[0035] S1. Condensation: Add 255-265kg of vitamin C, 200-250kg of acetone dimethyl acetal, 800-850kg of DMSO and 4.5-5.5kg of catalyst into the reaction tank for condensation reaction. The catalyst is p-toluenesulfonic acid Or the pyridinium salt of p-toluenesulfonic acid, and the molar ratio of catalyst to acetone dimethyl acetal is 1: (65-85), the reaction temperature is controlled at 25-35°C, and the reaction time is 2.5-4.5h; after the reaction is completed, put it in the reaction tank Add 4.5-5.5kg of sodium bicarbonate to neutralize the condensation product, and then separate methanol and residual acetone dimethyl acetal by distillation;

[0036] S2. Etherification: Add 200-...

Embodiment 2

[0040] This embodiment provides a production process of Vc ethyl ether, which is a further optimization of the scheme of Example 1. The production process specifically includes the following steps:

[0041]S1. Condensation: 260kg of vitamin C, 215.2 of acetone dimethyl acetal, 813kg of DMSO and 5.1kg of p-toluenesulfonic acid are added to the reaction tank for condensation reaction, the reaction temperature is controlled at 28.0°C, and the reaction time is 3.5h; the reaction is over Add 4.96kg of sodium bicarbonate and the condensation product in the reaction tank to neutralize, then separate methanol and residual acetone dimethyl acetal through distillation;

[0042] S2. Etherification: Add 210kg of sodium bicarbonate and 4.0kg of water to the condensation product after distillation, mix well, then dissolve 255kg of bromoethane in DMSO 0.5 times its volume in advance to obtain a mixed solution, and then Add the mixed solution dropwise to the condensation product for etherific...

Embodiment 3

[0046] A production process of Vc ethyl ether is basically the same as in Example 2, except that in step S4, no isopropyl acetate is added after cooling and crystallization, and the crystals are collected by centrifugation directly. The finished product yield of Vc ethyl ether was 65.1%, and the purity was 99.3%. When no isopropyl acetate was added, the yield of Vc ethyl ether decreased, and the purity had little influence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com