Damping-adjustable polyurethane material and its preparation method and application thereof

A technology of polyurethane materials and polyurethane prepolymers, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of high natural frequency of magnetorheological elastomers, high resonance frequency, poor high-frequency vibration damping effect, etc., to reduce vibration The effect of transmissibility and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a polyurethane material with adjustable damping, comprising the steps of:

[0024] (1) take polyurethane prepolymer, chain extender, magnetic particle and coupling agent by weight;

[0025] (2) Stir the polyurethane prepolymer, chain extender, magnetic particles and coupling agent evenly to obtain a premix;

[0026] (3) Pour the premixed material into a mold and mold it at 80-150° C. for 30 minutes to obtain a polyurethane material with adjustable damping.

[0027] The polyurethane material with adjustable damping prepared by the present invention can be applied to prepare shock absorbers, such as a shock absorber with controllable stiffness and damping disclosed in Chinese patent 200510038642.1.

Embodiment 1

[0030] combine figure 1 Illustrative Example 1

[0031] Preparation of polyurethane material with adjustable damping:

[0032] Weigh 100g of polyurethane prepolymer with an isocyanate index of 2%, 2g of chain extender 1,4-butanediol, 15g of carbonyl iron powder and 0.3g of Si69, mix them evenly, pour them into a mold, and press at 100°C for 30min , the polyurethane material with adjustable damping is obtained.

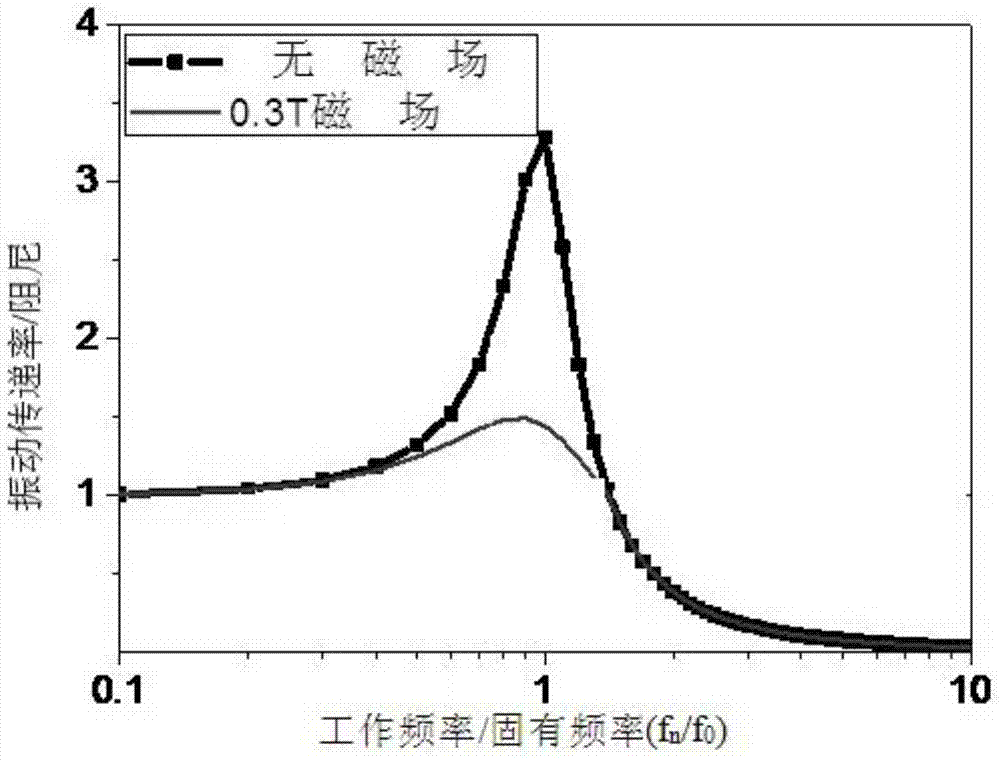

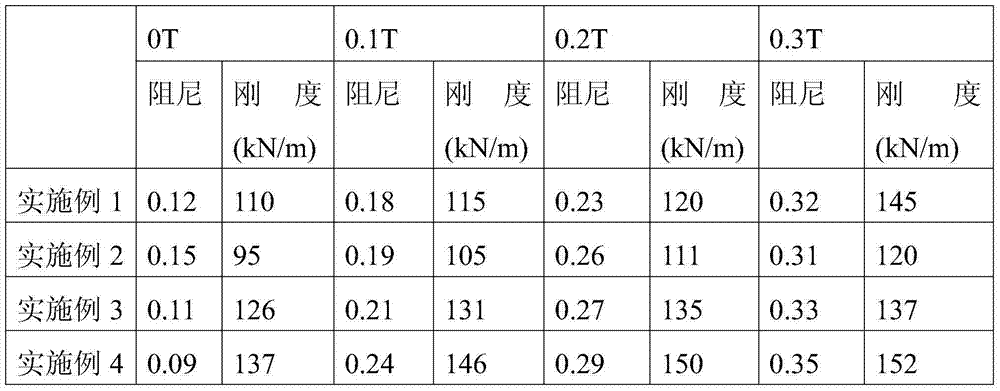

[0033] figure 1 It is the relationship curve of the ratio of vibration transmissibility to damping of the material as a function of operating frequency in the case of the polyurethane material in Example 1 of the present invention with or without a magnetic field. It can be seen from the figure that the damping of the polyurethane material of the present invention can change significantly with the external magnetic field, and under the influence of the magnetic field of 0-0.3T, its damping increases from 0.12 to 0.32, which increases nearly three times.

Embodiment 2

[0035] Preparation of polyurethane material with adjustable damping:

[0036] Weigh 100g of polyurethane prepolymer with an isocyanate index of 5.3%, 5g of chain extender 1,3-butanediol, 5g of 3,3′-dichloro-4,4′-diaminodiphenylmethane, 5g of nickel carbonyl and 0.1g of Si75, mixed evenly, poured into a mold, and molded at 100°C for 30 minutes to obtain a polyurethane material with adjustable damping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com