Preparation method of bionic gecko adhesive tape

A technology of adhesive tape and gecko, applied in the field of imitation gecko foot setae, can solve the problems of high cost, difficult demoulding, complicated operation, etc., and achieve the effect of low cost, simple operation, and controllable experimental parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific implementation mode 1: This implementation mode prepares Cu(OH) according to the following steps 2 / PDMS composite imitation gecko foot microarray:

[0020] Step 1: Preparation of Cu(OH) by in-situ electrochemical etching 2 Microarray:

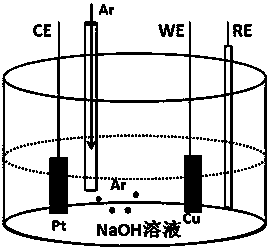

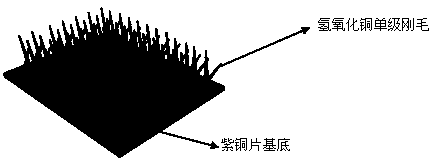

[0021] The electrochemical reaction cell for preparing CuO pine needle arrays by in-situ electrochemical etching method is a one-chamber electrolytic cell (see figure 1 ). The copper strip (11 cm × 11 cm) is the working electrode (WE), and the platinum electrode (area A ≈ 1.0 cm 2 ) is the counter electrode (CE), the saturated calomel electrode is the reference electrode (RE), and sodium hydroxide (NaOH) is the electrolyte. Before the experiment, argon gas was passed for about 20 min to remove the gas in the electrolyte. The control current density range is 0.1-10 mA / cm 2 And the electrolyte concentration range is 0.5-10mol / L, the reaction time range is 2-60min, and a layer of blue Cu(OH) is formed on the surface of the c...

specific Embodiment approach 2

[0025] Specific embodiment two: this embodiment prepares imitation gecko foot microarray according to the following steps:

[0026] 1. Cu(OH) 2 Microarray preparation

[0027] The electrochemical reaction cell for preparing CuO pine needle arrays by in-situ etching method is a one-chamber electrolytic cell. The copper strip (1 cm×1 cm) is the working electrode (WE), and the platinum electrode (area A≈1.0 cm 2 ) is the counter electrode (CE), the saturated calomel electrode is the reference electrode (RE), and sodium hydroxide (NAOH) is the electrolyte. Before the experiment, the copper strip needs to be washed with acid, water and alcohol. The reaction tank was ventilated with argon gas for about 20 minutes to remove the gas in the electrolyte. Control the current density to 0.5mA / cm 2 And the electrolyte concentration is 1mol / L, the reaction time is 15min, and a layer of blue Cu(OH) is formed on the surface of the copper strip. 2 film. Take out the copper tape with the...

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment prepares imitation gecko foot microarray according to the following steps:

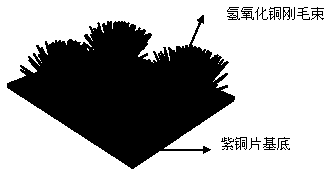

[0032] 1. Cu(OH) 2 Preparation of microarrays.

[0033] The electrochemical reaction cell for preparing CuO pine needle arrays by in-situ etching method is a one-chamber electrolytic cell. The copper strip (1 cm×1 cm) is the working electrode (WE), and the platinum electrode (area A≈1 cm 2 ) is the counter electrode (CE), the saturated calomel electrode is the reference electrode (RE), and sodium hydroxide (NAOH) is the electrolyte. Before the experiment, the copper strip needs to be washed with acid, water and alcohol. The reaction tank was ventilated with argon gas for about 20 minutes to remove the gas in the electrolyte. Control the current density to 1.3mA / cm 2 And the electrolyte concentration is 4mol / L, the reaction time is 15min, a layer of blue Cu(OH) is formed on the surface of the copper strip 2 film. Take out the copper tape with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com