High linear pressure water-squeezing big roller and manufacturing method thereof

A technology of large rollers and high wire, applied in the field of refining machines for viscose staple fiber manufacturing, can solve the problems of short service life, unevenness of water-squeezed bearing objects, and reduced displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

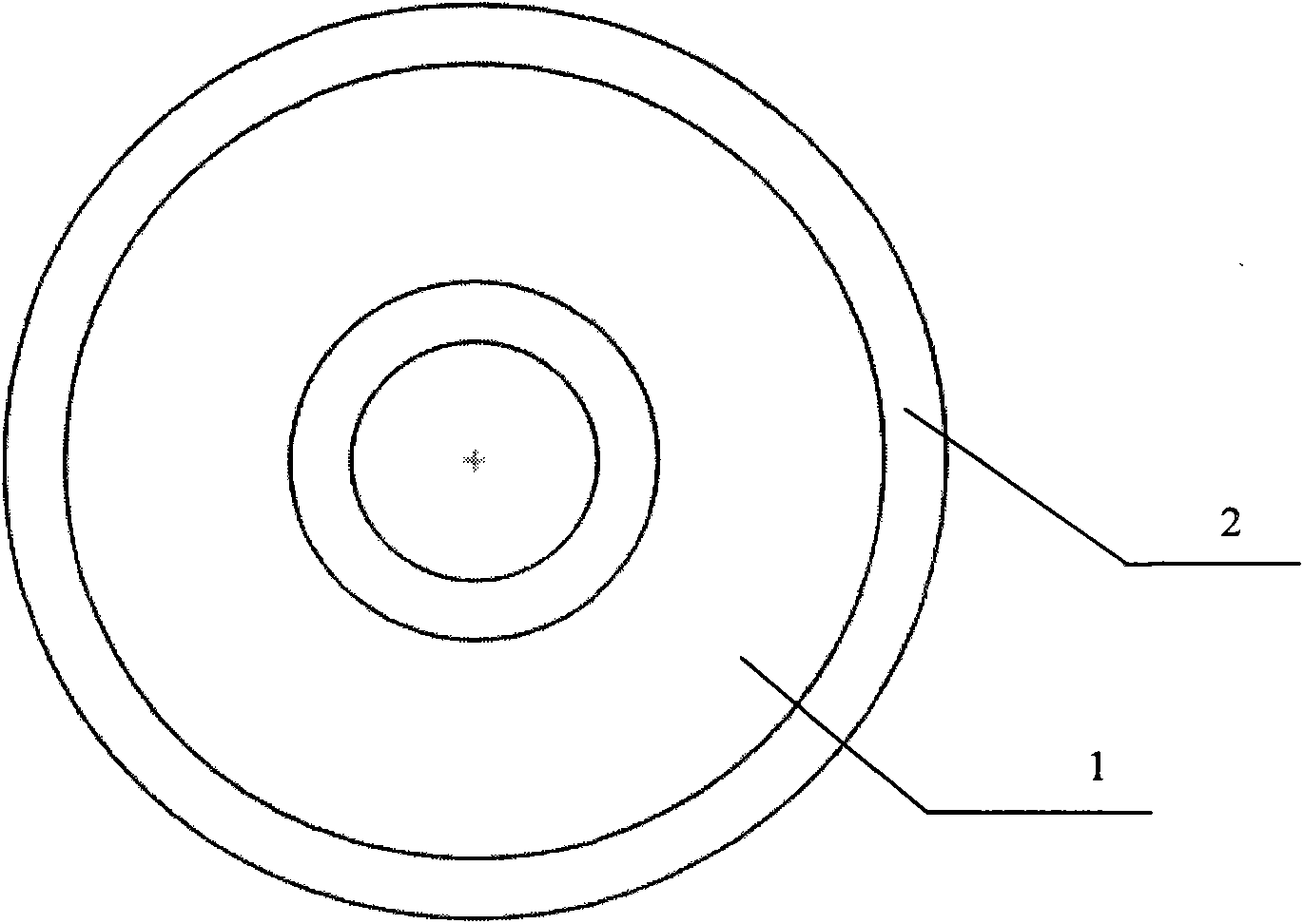

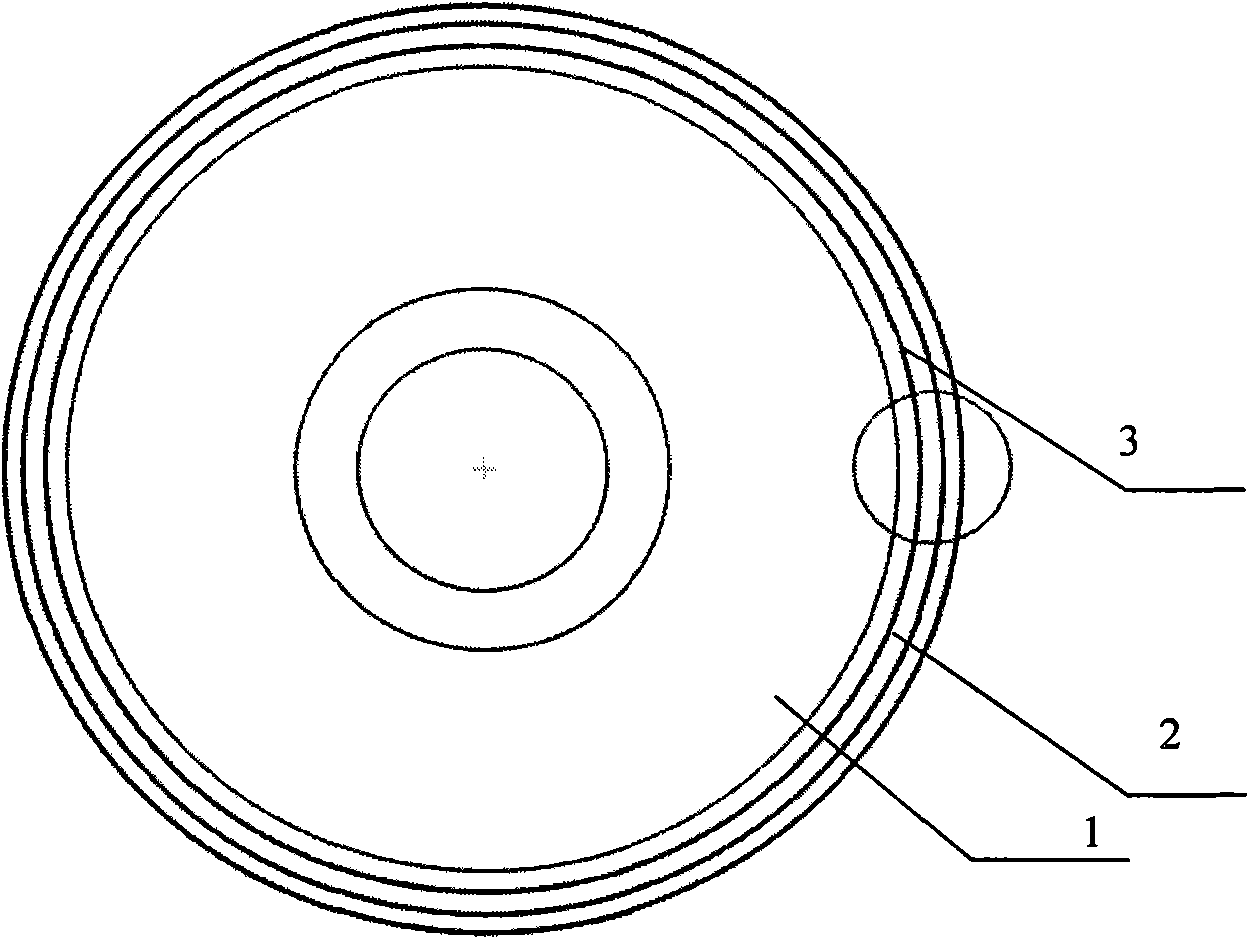

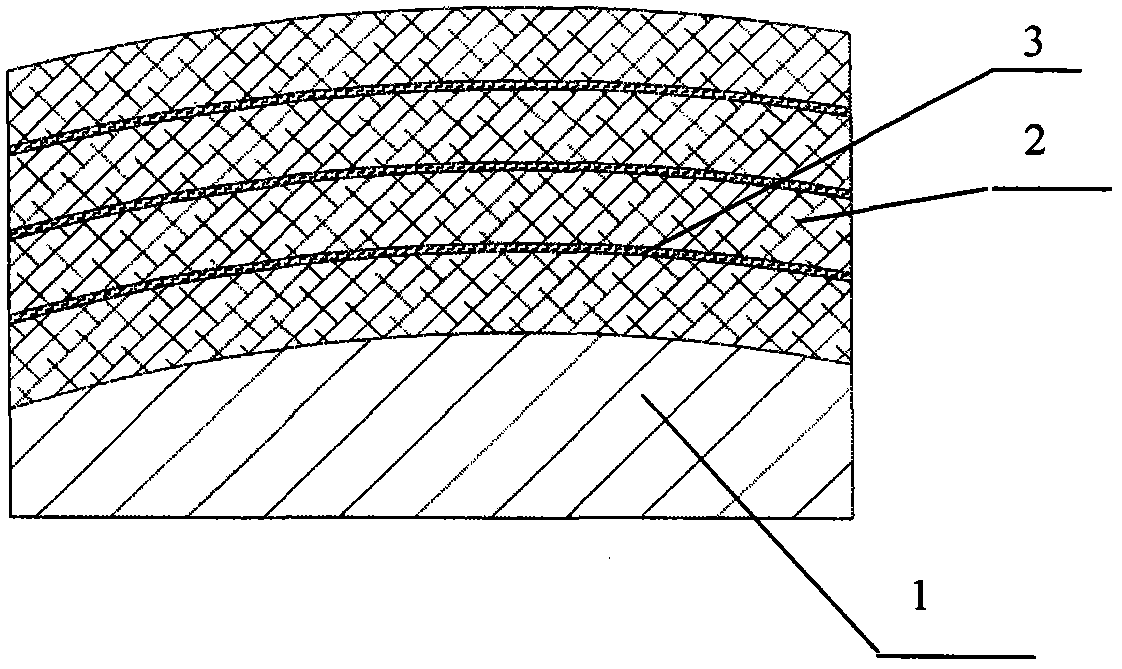

[0019] Embodiment 1: A large roll with high linear pressure, including the shaft core 1 and the rubber layer 2 covering the outer surface of the shaft core 1. It is characterized in that, in the rubber layer 2, 6 layers of nylon reinforcement layers 3 are added to improve the rubber layer. Excellent anti-displacement ability, improve the tear resistance of the adhesive layer. Wherein the shaft core 1 is an iron core, and the material of the nylon reinforcing layer 3 is selected from nylon 66 cord. The preparation process includes sandblasting, cleaning, adhesive brushing, drying, and glue brushing on the shaft core 1 in sequence. After the glue is dried, it is wound and formed by a winding molding machine. Specifically, a layer of 6 mm thick is wound on the surface of the iron core 1. For the rubber layer, wrap a layer of cord strips at an angle of 30-45 degrees, and then wrap a layer of cord strips across the head. After wrapping two layers of 4-6mm thick rubber layers, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com