Real-time image observation and acquisition platform and method for microstructure of material with loads

A microscopic technology of tissue structure and materials, applied in the analysis of materials, measuring devices, instruments, etc., can solve the problem of not proposing observable material mechanics test equipment and quantitative research methods of microscopic tissue damage, inconvenient real microscopic mechanical behavior and deformation damage mechanism, Problems such as the acquisition and analysis of mechanical data association of microstructure damage and materials have not been realized, and the effect of simple structure, sensitive response and easy operation has been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

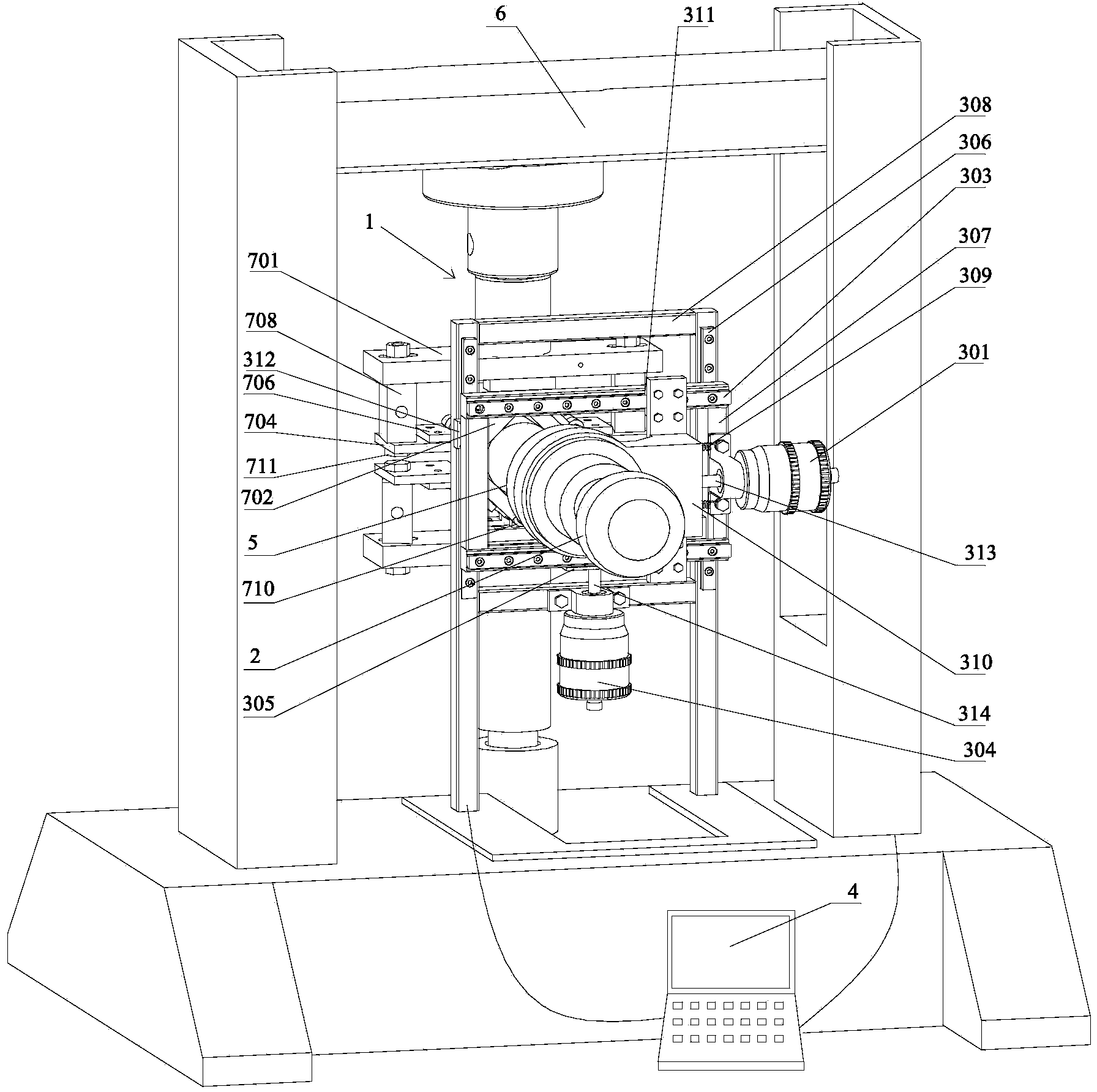

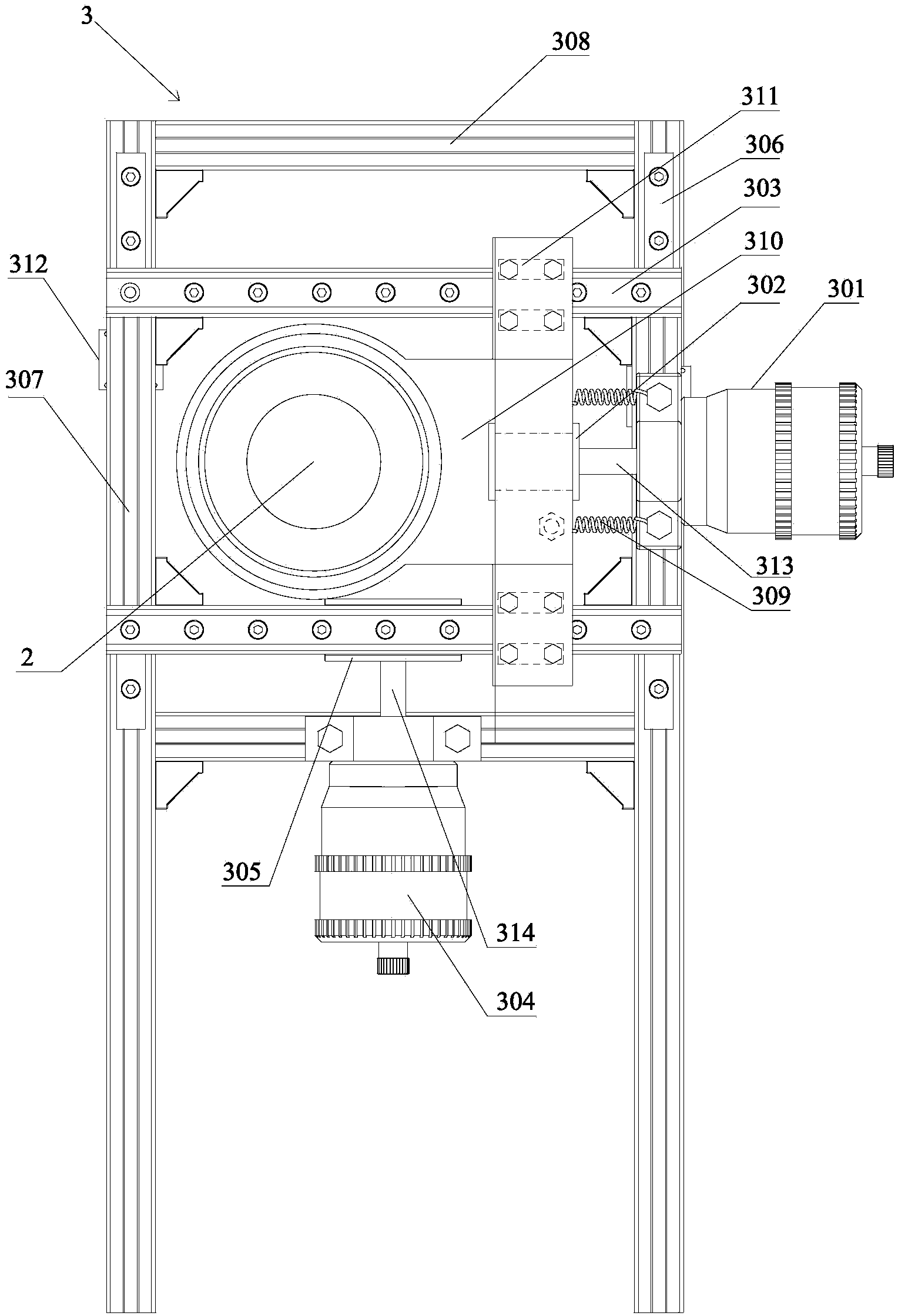

[0044] like Figure 1-Figure 3 As shown, the platform for real-time image observation and acquisition of the microstructure of materials under loading in this embodiment includes a loading device 1 , an image observation and capture device 2 , an XY dual-coordinate micro-control movement device 3 and a PC 4 .

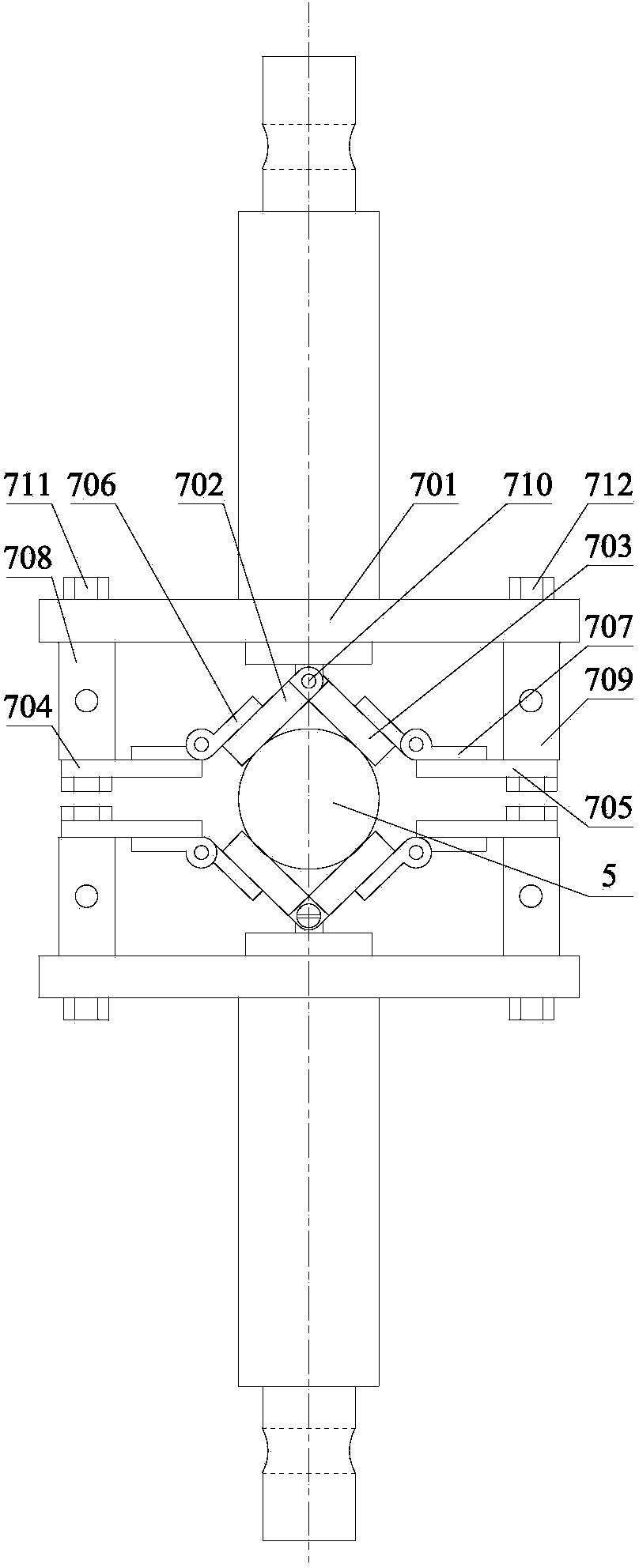

[0045] The loading device 1 is used to compress the test material 5 and obtain material mechanical data, including a universal material testing machine 6 and a set of angle-adjustable multifunctional fixtures 7, which can meet various shapes 1. The clamping of the diameter material is made up of two multifunctional fixtures 7, and the two multifunctional fixtures 7 are symmetrical to each other, and are respectively installed at the upper pressure head and the lower pressure plate of the universal material testing machine 6, and the universal material The testing machine 6 is connected with the PC 4 through a data line.

[0046] Described each multifunctional fixture 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com