Virtual test method of plastic forming property of particle reinforced aluminum matrix composite

A particle-reinforced aluminum and composite material technology, applied in the direction of instruments, electrical digital data processing, special data processing applications, etc., can solve the problems of affecting the plastic formability of composite materials, only considering one or two types of damage, and high experimental costs. Achieve the effects of reducing types and quantities, accurate virtual forecasting, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] In this embodiment, 20% (volume fraction) SiC is selected p / 2009Al composite material is used as the implementation object, and the virtual test process of composite material tensile formability is simulated in ABAQUS finite element software.

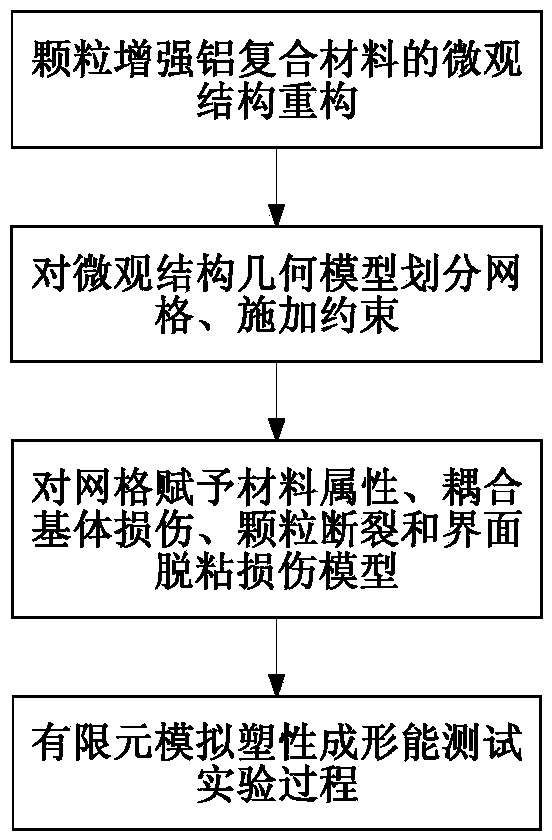

[0032] Such as figure 1 As shown, the virtual test method for plastic formability of composite materials of the present invention mainly includes the following steps:

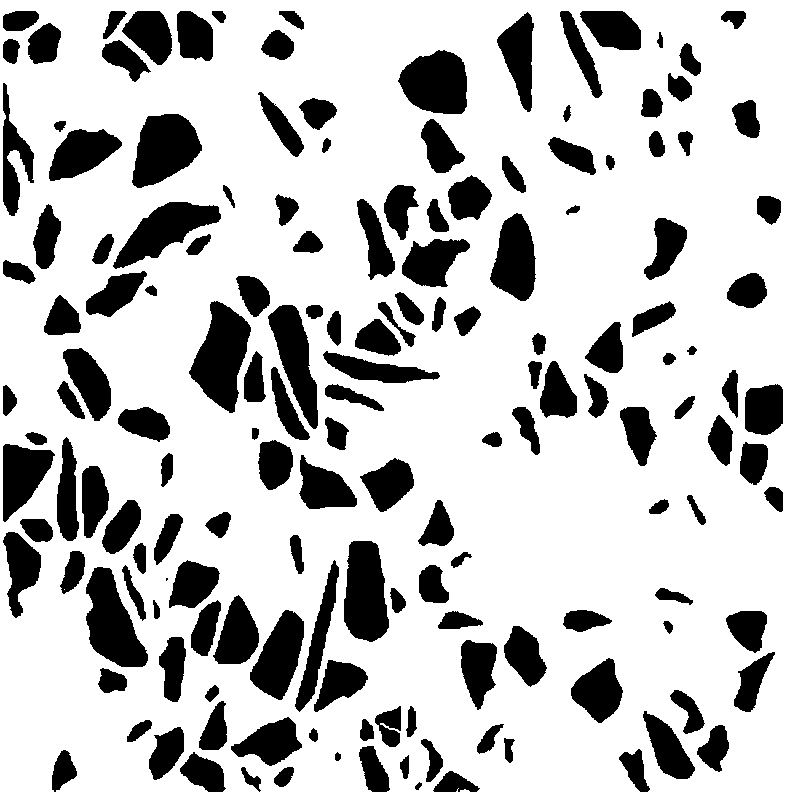

[0033] (1) Use X-ray scanning technology to analyze 20% (volume fraction) SiC p The microstructure of / 2009Al composite is reconstructed. Comprehensive consideration of 20% (volume fraction) SiC p The typical periodic structure characteristics of / 2009Al composites and to improve the calculation efficiency of the model, select a 50μm×50μm area for reconstruction, and the reconstructed microstructure is as follows figure 2 Shown.

[0034] (2) Using object-oriented finite element technology to figure 2 The microstructure shown is meshed. The four-node bilinear quadrila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com