IGBT driving circuit of converter for electric locomotive

A technology for electric locomotives and driving circuits, applied in electrical components, output power conversion devices, etc., can solve problems such as the inability of IGBT converters to operate safely and reliably, the limited driving capability of integrated drive chips, and the inability to meet flexible adjustment of line protection capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

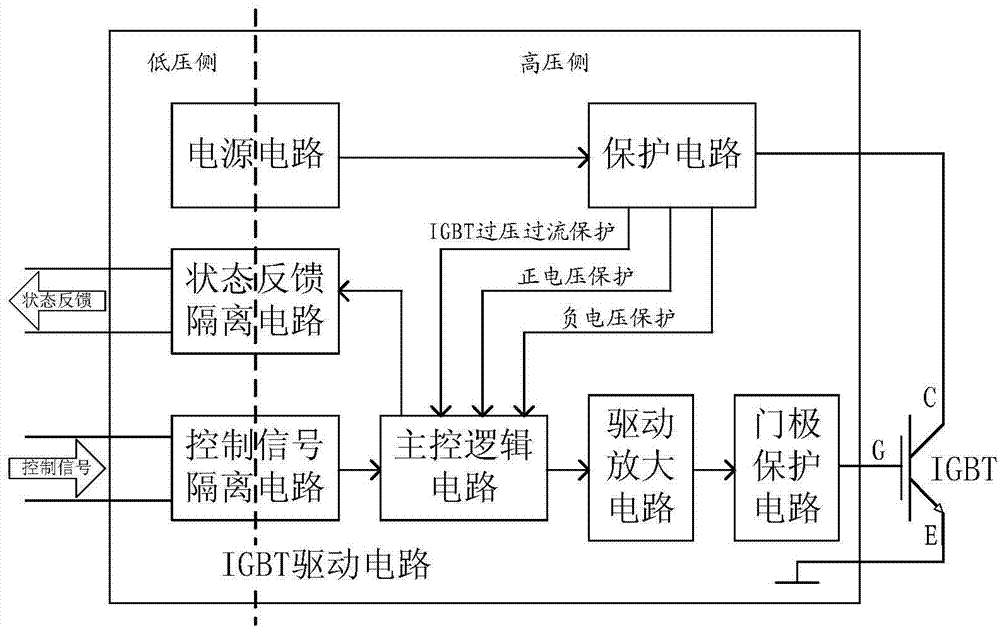

[0101] Such as Figure 1 to Figure 8 As shown, an IGBT driving circuit of a converter for an electric locomotive is connected between the main control unit of the electric locomotive and the IGBT of the converter, and its specific structure can adopt the above-mentioned technical scheme.

Embodiment approach

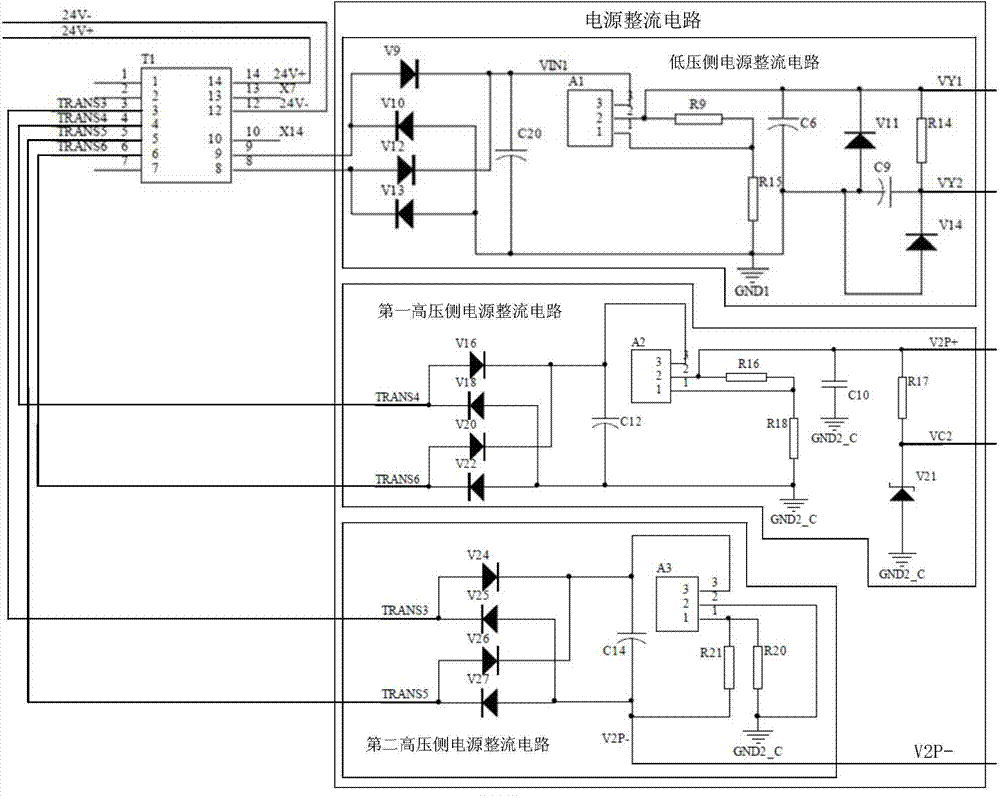

[0103] (1) in figure 2 In the circuit shown, the first pulse transformer T1 can use three 1:1 winding transformers, the isolation voltage is AC1000V, the inductance value is about 300uH at 10kHZ, the resistance value of each winding is less than 100m ohms, and the working frequency is 35kHz.

[0104] (2) in figure 2 In the circuit shown, the first regulated power supply A1, the second regulated power supply A2 and the third regulated power supply A3 can use ST’s LD1086V, and the required + 15V and -15V voltage. The first four diodes V14 and the second one Zener diode V21 can use Fairchild's IN4733, and the required 5V voltage can be obtained by building peripheral circuits.

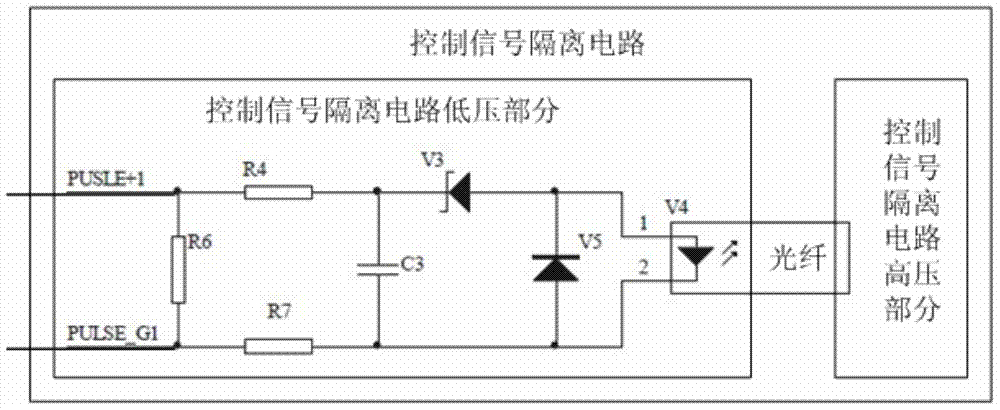

[0105] (3) at image 3 , Figure 4 and Figure 5 In the circuit shown, the first fiber optic transmitter V4 and the second fiber optic transmitter V15 can use AVAGO SFH756V, the first fiber optic receiver V6 and the second fiber optic receiver V2 can use Avago (AVAGO) ) SFH551 / 1-1V, the optical fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com