Degradable magnesium alloy nerve conduit for nerve defect repair and preparation method of nerve conduit

A technology of nerve conduits and magnesium alloys, which is applied in the fields of human tubular structure devices, medical science, tissue regeneration, etc., can solve the problems of difficult to precisely control the degradation time, unfavorable nerve axon regeneration, inflammatory response of surrounding tissues, etc., and achieve the realization time And catheter degradation time, smooth surface, to achieve matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

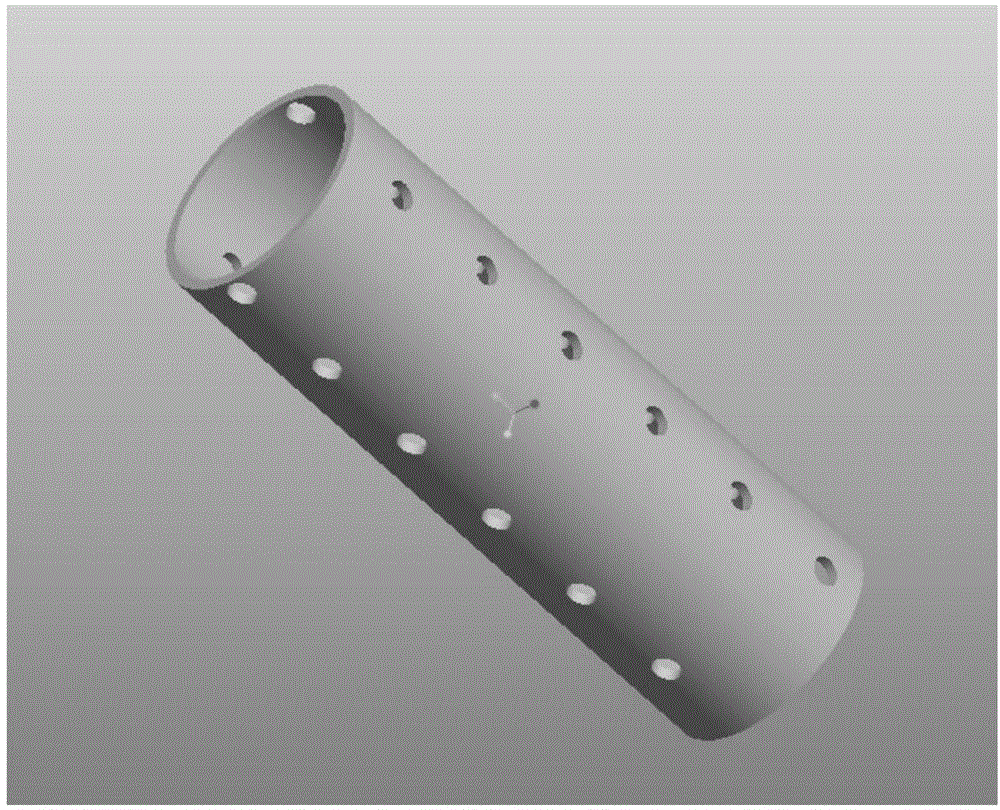

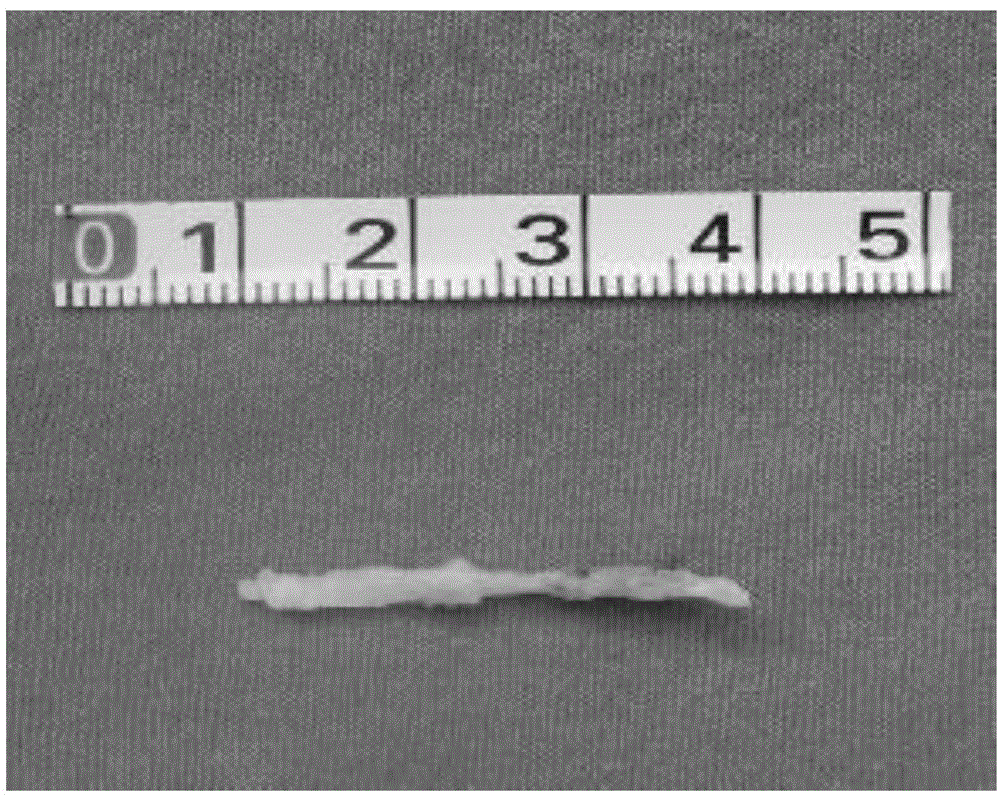

[0034] This embodiment relates to a degradable magnesium alloy nerve guide for nerve defect repair, its structure is as follows figure 1 As shown, the length is 6 mm, the outer diameter is 2 mm, and the wall thickness is 0.2 mm. The tube wall of the nerve guide is provided with 4 rows of through holes, and each row of through holes is arranged at equal intervals along the axis of the tube. , the through-holes in adjacent columns are staggered, the number of through-holes in each column is 6, and the hole diameter is 0.3mm.

[0035] This embodiment relates to the aforementioned method for preparing a degradable magnesium alloy nerve guide for repairing nerve defects, and the shown method includes the following steps:

[0036] Step 1, process one end of the Mg-Nd-Zn-Zr magnesium alloy tube billet with an outer diameter of 20mm to form a 45° conical surface, and extrude it at a temperature of 400°C to obtain a magnesium alloy intermediate tube (outer diameter × wall thickness);...

Embodiment 2

[0041] This embodiment relates to a degradable magnesium alloy nerve guide for nerve defect repair, its structure is as follows figure 1 As shown, the length is 50 mm, the wall thickness is 0.15 mm, and the outer diameter is 3 mm. The tube wall of the nerve guide is provided with 8 rows of through holes, and each row of through holes is arranged at equal intervals along the axis of the tube. , the through-holes in adjacent columns are arranged in dislocation, the number of through-holes in each column is 50, and the hole diameter is 0.03mm.

[0042] This embodiment relates to the aforementioned method for preparing a degradable magnesium alloy nerve guide for repairing nerve defects, and the shown method includes the following steps:

[0043] Step 1: Process one end of the Mg-Zn-Zr magnesium alloy tube billet with an outer diameter of 20mm to form a 45° conical surface, and extrude it at a temperature of 300°C to obtain a magnesium alloy intermediate tube (outer diameter × w...

Embodiment 3

[0048] This embodiment relates to a degradable magnesium alloy nerve guide for nerve defect repair, its structure is as follows figure 1 As shown, the length is 5 mm, the wall thickness is 0.10 mm, and the outer diameter is 1 mm. The tube wall of the nerve guide is provided with 4 rows of through holes, and each row of through holes is arranged at equal intervals along the axis of the tube. , the through-holes in adjacent columns are arranged staggered, the number of through-holes in each column is 5, and the hole diameter is 0.2mm.

[0049] This embodiment relates to the aforementioned method for preparing a degradable magnesium alloy nerve guide for repairing nerve defects, and the shown method includes the following steps:

[0050] Step 1: Process one end of the Mg-Zn-Mn magnesium alloy tube billet with an outer diameter of 20mm to form a 45° conical surface, and extrude it at a temperature of 320°C to obtain a magnesium alloy intermediate tube (outer diameter × wall thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com