Silicon block crushing method

A crushing method and silicon block technology, applied in grain processing, etc., can solve the problems of polluted silicon materials, high hardness, and large material loss, and achieve the effects of low equipment cost, high hardness, and compact tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

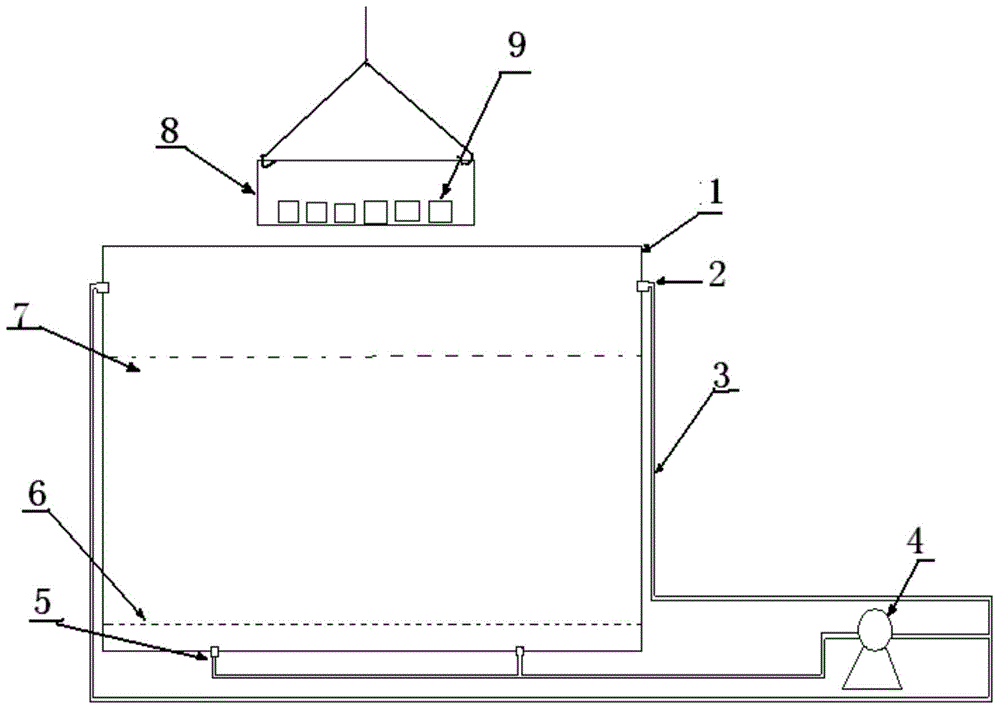

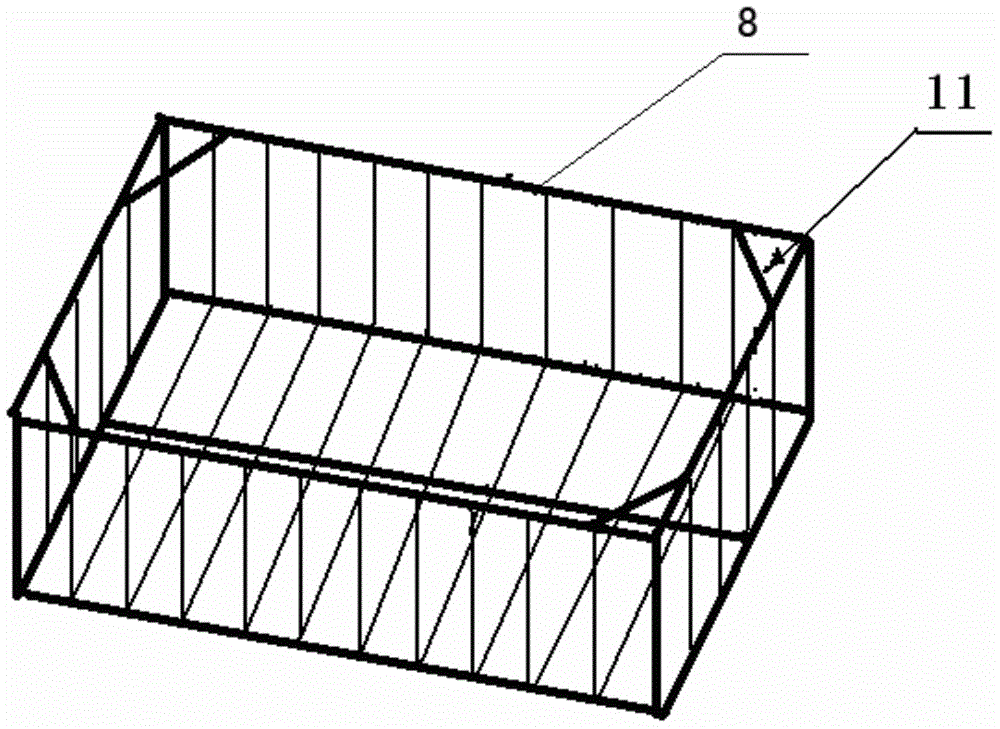

[0022] A method for crushing silicon blocks, which is characterized in that: the method is to put the strip-shaped silicon ingots 9 cut by a sawing machine into a basket 8, and then put the basket 8 containing the silicon blocks into a high-temperature resistance furnace, and heat When the temperature reaches the high temperature for a certain period of time, take out the material basket from the furnace and put it into the sink 1 containing cold pure water 7. When the temperature of the silicon material drops to the water temperature, lift the material basket, take out the silicon block, and tap it with a cemented carbide hammer. It can realize that the diameter of the broken particles of silicon material is less than 30mm;

[0023] The heating temperature of the silicon block material is 600~700°C, and the high temperature holding time is 2~4 hours;

[0024] The silicon block material is put into a cold water tank, immersed into the water surface at 80mm / s~130mm / s, and dropped at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com