Preparation method of KCu7S4 nano wire, and capacitor

A nanowire and capacitor electrode technology, which is applied in the field of electrode material synthesis, can solve the problems of high cost and obstacles to application, and achieve the effects of low synthesis cost, high energy density and power density, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Prepare three raw materials, each weighing 0.001mol copper chloride, 0.0005mol elemental sulfur and 3g (0.05mol) potassium hydroxide, and put them in a Teflon (Teflon) tube respectively.

[0039] (2) Add 2ml of absolute ethanol and 2ml of hydrazine hydrate to the above three Teflon tubes respectively, and seal them.

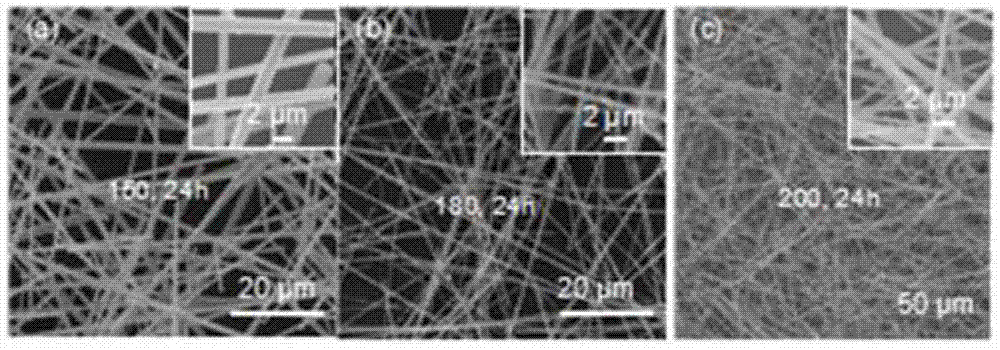

[0040] (3) Put the Teflon (Teflon) tubes prepared in step 2 into muffle furnaces for heating respectively. The heating temperatures are 200°C, 180°C, and 150°C respectively. After heating for 24 hours, tetrasulfide heptacopper-potassium is produced. Nanowires.

[0041] (4) Take out the Teflon (Teflon) tube in step 3, let it cool down to room temperature naturally, then take out the product inside, after ultrasonic cleaning with deionized water, dry at 60°C to get the product.

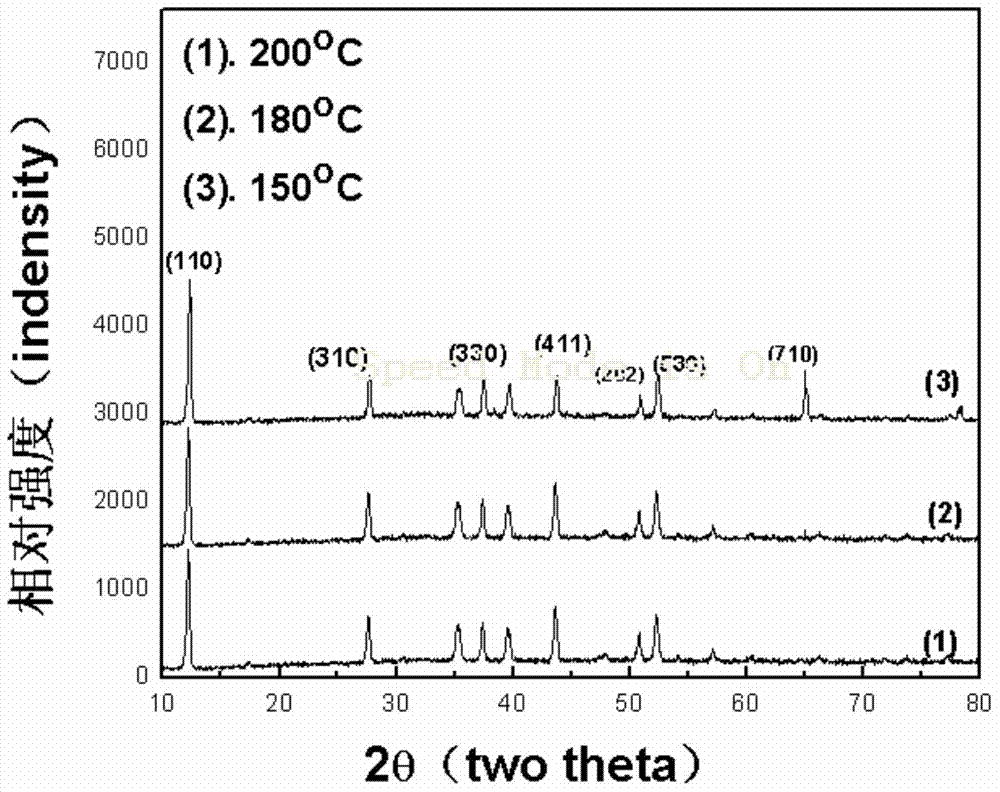

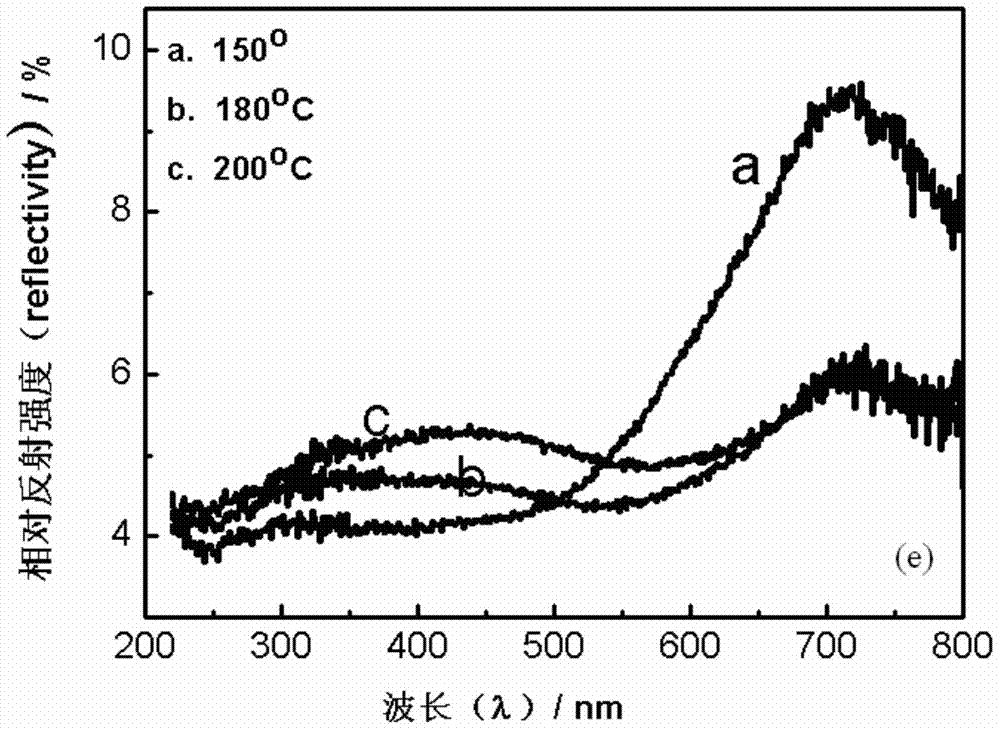

[0042] figure 1 The XRD pattern of tetrasulfide heptacopper-potassium nanowires prepared by the present invention shows that the product prepared by the present invention is i...

Embodiment 2

[0049] (1) Weigh 0.001mol of copper chloride, 0.0005mol of elemental sulfur and 3g (0.05mol) of potassium hydroxide, and place them in a Teflon (Teflon) tube respectively.

[0050] (2) Add 1.8ml of absolute ethanol and 1.8ml of hydrazine hydrate to the above reaction vessel, and seal it.

[0051] (3) Put the reaction container prepared in step 2 into an oven for heating at 120° C., and generate tetrasulfide heptacopper-potassium nanowires after heating for 48 hours.

[0052] (4) Take out the Teflon (Teflon) tube in step 3, cool it with water to room temperature, then take out the product inside, ultrasonically clean it with deionized water or absolute ethanol, and dry it at 60°C.

[0053] (5) Two tetrasulfide heptacopper-potassium nanowires were pressed into thin films at an atmospheric pressure of 8 MPa, and the two tetrasulfide heptacopper-potassium nanowire films were respectively fixed on the carbon block.

[0054] (6) 1 mg and 2 mg of manganese nanoparticle layers were p...

Embodiment 3

[0058] (1) Prepare four raw materials, each weighing 0.001mol copper chloride, 0.0005mol elemental sulfur and 3g (0.05mol) potassium hydroxide, and put them in a Teflon (Teflon) tube respectively.

[0059] (2) Add 2.2ml of absolute ethanol and 2.2ml of hydrazine hydrate to the above reaction vessel respectively, and seal it.

[0060] (3) The reaction containers prepared in step 2 were respectively placed in an oven for heating at a temperature of 240° C., and tetrasulfide heptacopper-potassium nanowires were formed after heating for 10 hours.

[0061] (4) Take out the Teflon (Teflon) tube in step 3, cool it down to room temperature naturally, then take out the product inside, ultrasonically clean it with deionized water or absolute ethanol, and dry it at 60°C.

[0062] (5) Four parts of tetrasulfide heptacopper-potassium nanowires were pressed into thin films under an atmospheric pressure of 15 MPa, and the tetrasulfide heptacopper-potassium nanowire films were respectively fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com