Preparation method of acid modified caustic calcined magnesite printing and dyeing wastewater treatment agent

A technology for treating chemicals, printing and dyeing wastewater, applied in textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as environmental impact, resource waste, white pollution, etc., and achieve simple preparation process, low cost, and product performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

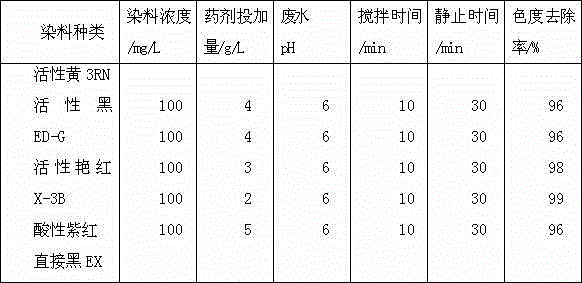

[0018] Add 300g of lightly burned magnesium powder (75% MgO content) into a 500mL large beaker, slowly add 240mL of industrial hydrochloric acid with a mass fraction of 3%, stir while adding, continue to stir and mix for 10min, after static activation for 20min, heat in a microwave oven Modified and dried, taken out and cooled, and ground into powder, that is the prepared light-burned magnesium printing and dyeing wastewater treatment agent product. This product is used to treat five kinds of dye simulated wastewater commonly used in printing and dyeing factories, and a good treatment effect has been received. The processing results are shown in Table 1.

[0019] Table 1 water treatment agent decolorization effect on various dye wastewater

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com