Spinning process of a high-speed spinning machine

A technology of high-speed spinning and spinning technology, which is applied in the field of spinning technology, and can solve problems such as low spinning speed, pollution of winding devices, and reduced product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

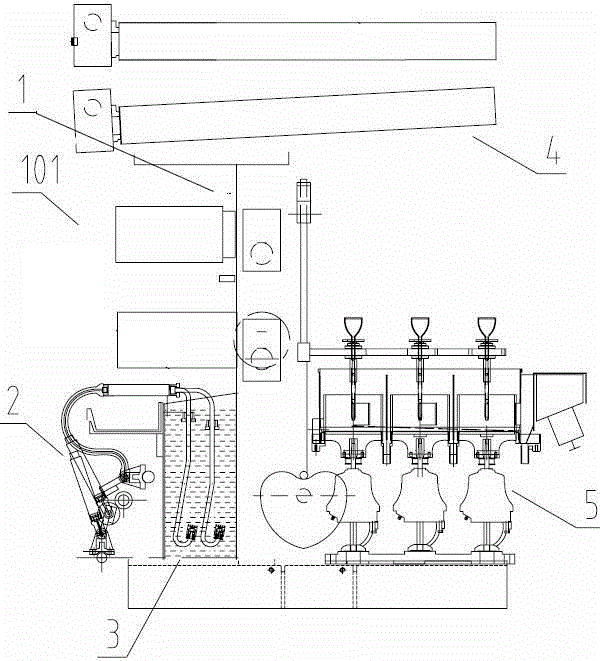

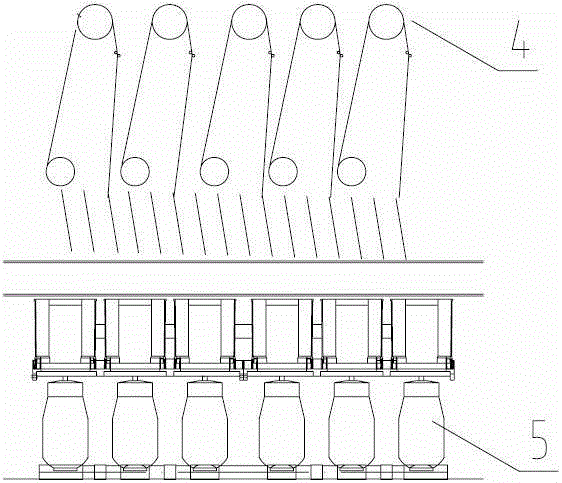

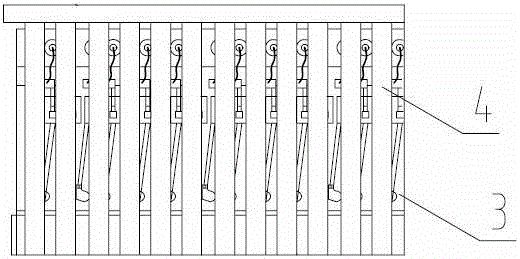

[0251] A spinning process of a high-speed spinning machine, including glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament forming device 3 , the spinning is completed by the spinning device 4, and the winding is completed by the winding device 5, and the spinning device 4 includes at least one group of spinning rolls, and each group of spinning rolls includes a The upper spinning roll 401 and the lower spinning roll 402, the two ends of the upper spinning roll 401 and the lower spinning roll 402 are fixed, and the upper spinning roll 401 and the lower spinning roll 402 are rotated by the synchronous belt 403, and the In the axial direction of the spinning roll, a washing device 41 is arranged between the two spinning rolls. Between the two spinning rolls, an oiling device 42 is provided at the rear of the lower spinning roll 402; the winding device 5 The forming par...

Embodiment 2

[0258] A spinning process of a high-speed spinning machine, including glue supply, filament forming, spinning and winding, the glue supply is completed by the glue supply device 2, and the filament forming is completed by the filament forming device 3 , the spinning is completed by the spinning device 4, and the winding is completed by the winding device 5, and the spinning device 4 includes at least one group of spinning rolls, and each group of spinning rolls includes a The upper spinning roll 401 and the lower spinning roll 402, the two ends of the upper spinning roll 401 and the lower spinning roll 402 are fixed, and the upper spinning roll 401 and the lower spinning roll 402 are rotated by the synchronous belt 403, and the In the axial direction of the spinning roll, a washing device 41 is arranged between the two spinning rolls. Between the two spinning rolls, an oiling device 42 is provided at the rear of the lower spinning roll 402; the winding device 5 The forming par...

Embodiment 3

[0265] A step 405 is provided at the front of the upper spinning roll 401 , and the diameter of the step 405 is smaller than that of the rest of the upper spinning roll 401 .

[0266] The diameter of the step 405 is 10% different from the diameter of the rest of the upper spinning roll 401 .

[0267] The water washing device 41 is located in the middle section of the spinning roll.

[0268] Described washing device 41 is 1 road.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com