System and method for testing performance of fluorescent powder

A test system and fluorescent powder technology, applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of complex operation, large test error, high cost, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Further illustrate below in conjunction with accompanying drawing and specific embodiment:

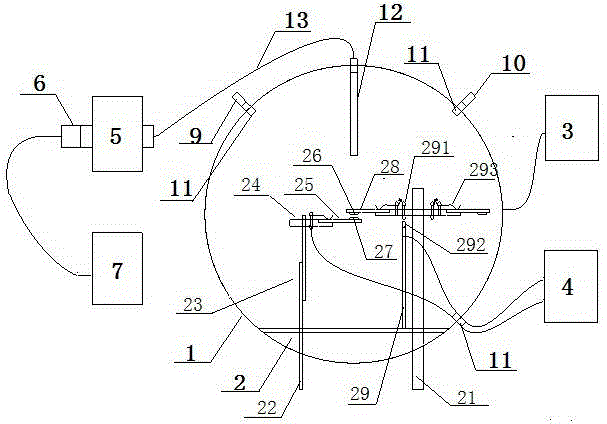

[0058] Such as figure 1 In the specific embodiment shown, the fluorescent powder performance testing device system of the present invention includes a vacuum sample chamber 1, a test platform 2, a vacuum device 3, a high voltage power supply 4, an excitation source, an acquisition optical fiber, a monochromator 5, and a single photon counter 6 and data processor 7 .

[0059] The test platform includes a main support, a cathode support and a sample support. The cathode support includes a cathode support rod 22 and a cathode support plate 24. The cathode support plate 24 is connected to the cathode support rod 22 by a linear guide rail 23 and is installed perpendicular to the cathode support rod 22. FED cathode sheet 25 is installed on the cathode sheet supporting plate 24, has cathode test area 27 on the FED cathode sheet 25; On the sample pallet, the sample piece 28 has a samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com