An explosion vibration sensor installation clamp applicable to soil mediums

A blasting vibration and fixture installation technology, applied in the direction of seismic signal receivers, etc., can solve the problems of increasing the workload of testers, unable to obtain valid data, and insufficient strength of bonding materials, and achieves simple structure, fast installation speed, and reduced work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The first step: select the location of the measuring point and remove the surface covering soil. A large amount of covering soil will seriously affect the stability of the entire sensor installation;

[0022] The second step: determine the installation direction, determine the relative direction of the sensor and the explosion source according to the actual test requirements, usually point the X direction of the lower splint 2 to the direction of the explosion source;

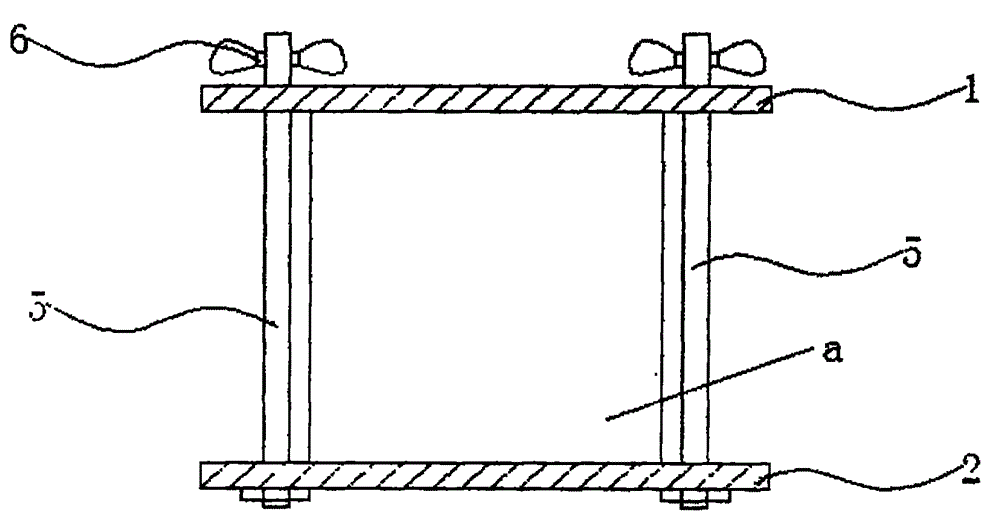

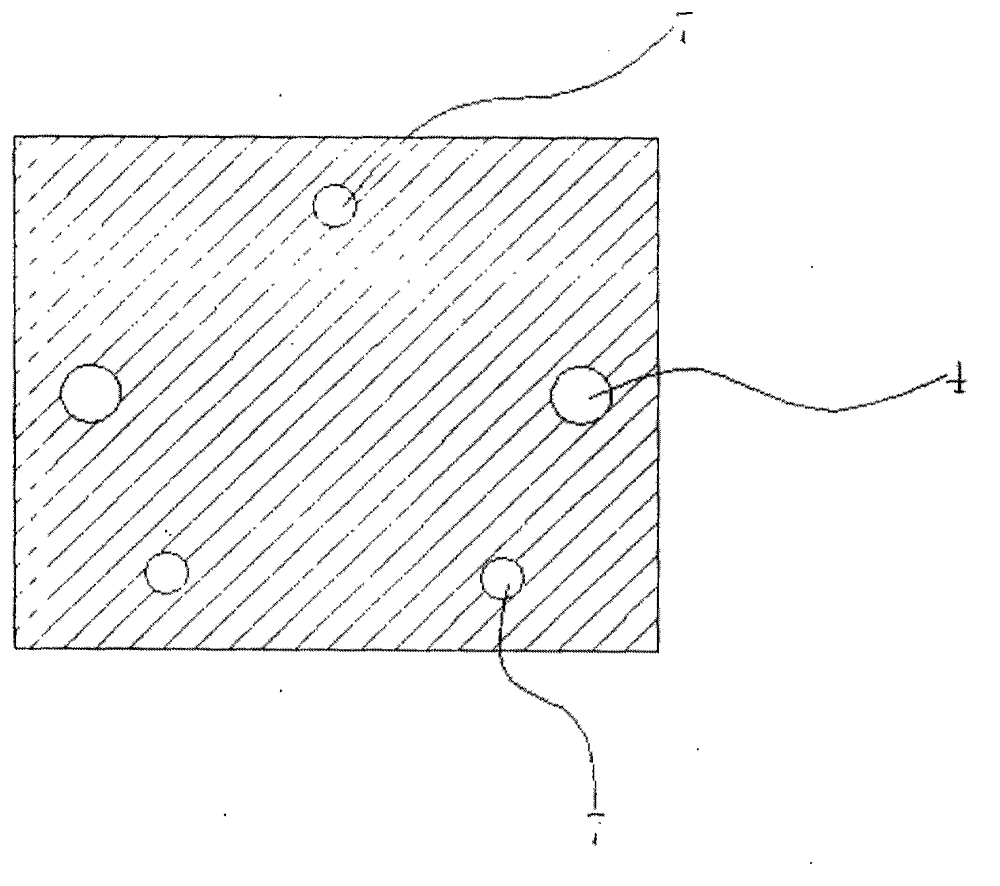

[0023] The third step: pass the steel nail through the fixing hole 7, knock it into the soil with a hammer, and fix the lower splint 2;

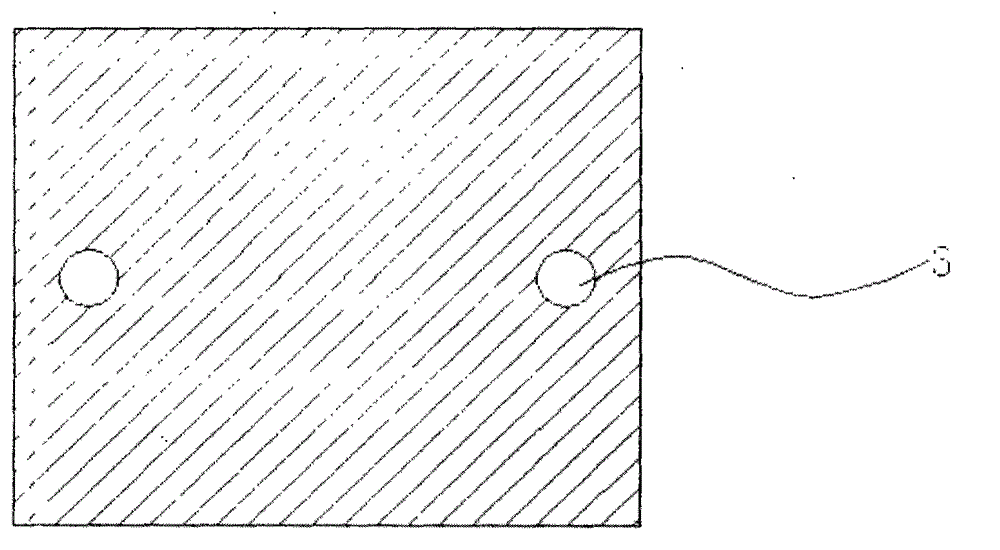

[0024] Step 4: align the X direction of the blasting vibration sensor a with the X direction of the bottom clamping block, and clamp and fix the blasting vibration sensor a between the upper splint 1 and the lower splint 2 through the screw 5 and the fixed nut 6;

[0025] Step 5: Connect the lead wire of the blasting vibration sensor a to the data recorder, and the vib...

Embodiment 2

[0027] The blasting seismic wave curve tested in the typical field soil medium in this embodiment is as follows: Figure 4~6 shown. This time is a typical expressway pile hole excavation blasting. The nonel nonel micro-differential detonation method is used for detonation. The cut hole is connected by 1 section of nonel detonator, and the peripheral holes are connected by 9 sections of nonel detonator. The total amount is 7.6kg, and the maximum single-stage charge is 4.8kg. The measuring point is arranged at a distance of 5m from the edge of the pile hole, and the pile hole has been excavated to a depth of 10.2m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com