Ultrasonic-assisted spraying drainage and atomization dust removal device

A technology of auxiliary injection and dust removal device, which is applied in the direction of combination device, auxiliary pretreatment, chemical instrument and method, etc., can solve the problems of complex structure, easy to burn bags, large resistance of bag type dust removal, etc., and achieves compact overall structure and low cost of use. Low, good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

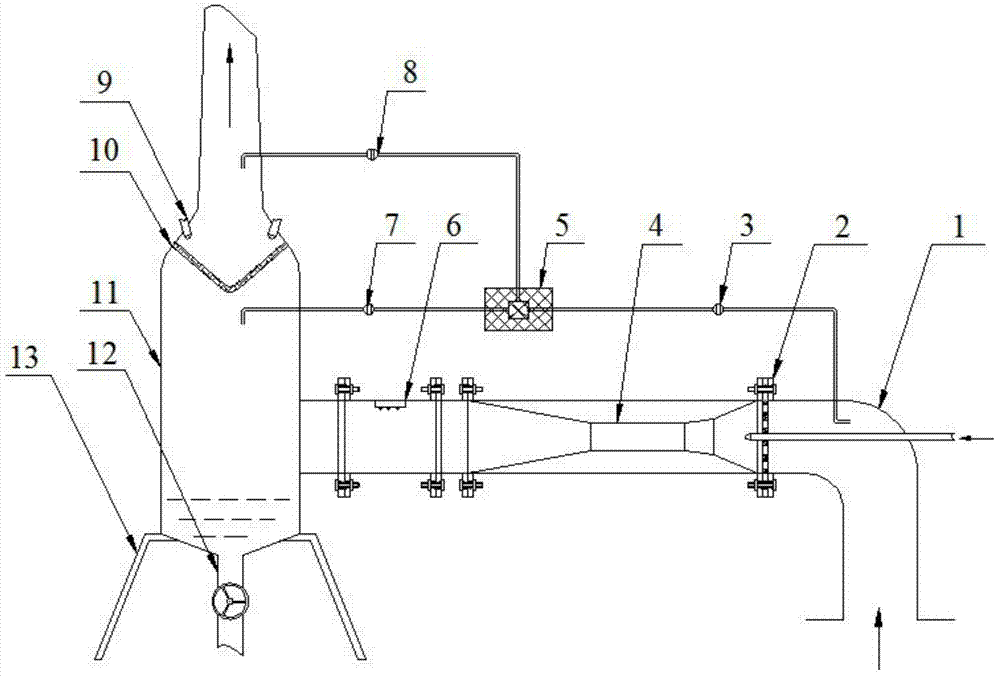

[0019] The structure and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The ultrasonic-assisted jet drainage atomization dust removal device of the present invention is mainly composed of a flue gas elbow 1, a flange set 2, a pre-stage sampler 3, a jet drainage device 4, a sampling analyzer 5, an ultrasonic generator 6, an intermediate sampler 7, Rear-stage sampler 8, timing cleaner 9, conical filter screen 10, coagulation and separation chamber 11, sewage pipe 12, and bracket 13 are composed.

[0021] The jet diverter 4 is horizontally connected to the flange on the flue gas elbow 1 through an external flange. The flange group 2 is composed of the jet diverter shell flange, nozzle flange, and flue gas elbow flange. The nozzle method The blue plate is placed in the middle, and the surface of the flange plate is symmetrically opened with a plurality of holes around the center of the circle to fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com