Universal intelligent back wash controller of biological aerated filter

A technology of biological aerated filter and biological filter applied in the field of controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

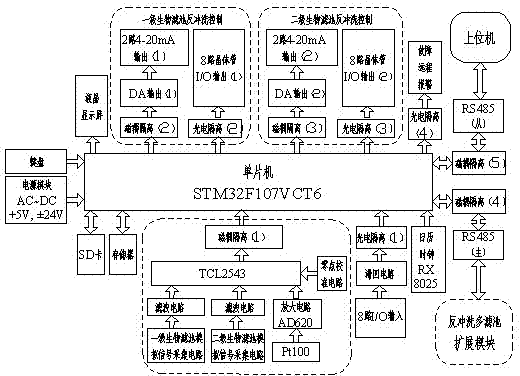

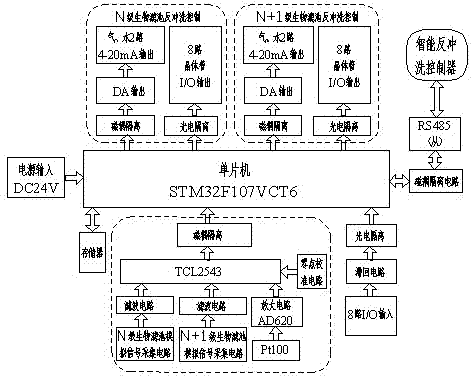

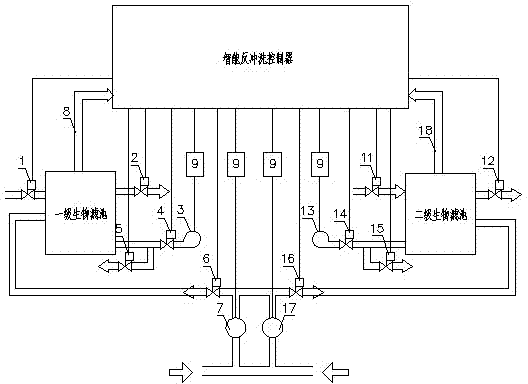

[0061] According to the specific implementation plan, the instruments, sensors and other control circuits are connected according to the markings according to the process requirements. The intelligent backwash controller can be modified on the original control system, or it can be used as a new system. The sewage treatment plant has a first-level biological filter and a second-level biological filter, or has a multi-level biological filter. The control system consists of parallel and independent control systems. The connection method depends on the specific situation, and the control method corresponds to it; through the screen setting Good parameters and control mode, the control mode is based on the type of sensor or instrument connected. The electrical cabinet of the intelligent backwash controller is mainly used for conventional power transmission, intermediate relay interlocking, frequency converter control, etc.

[0062] The intelligent backwash controller adopts two mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com