Preparation method of rare earth barium copper oxygen high-temperature superconducting film

A rare earth barium copper oxide, high temperature superconducting technology, applied in the field of high temperature superconducting materials, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

[0018] The present invention provides a method for preparing a rare earth barium copper oxide high temperature superconducting film. In one embodiment, the method includes the following steps:

[0019] a) Weigh the rare earth metal salt, barium salt, copper salt and doping element compound in proportion and disperse them in the solvent, and obtain a uniform precursor after stirring. Can generate oxides of doping elements;

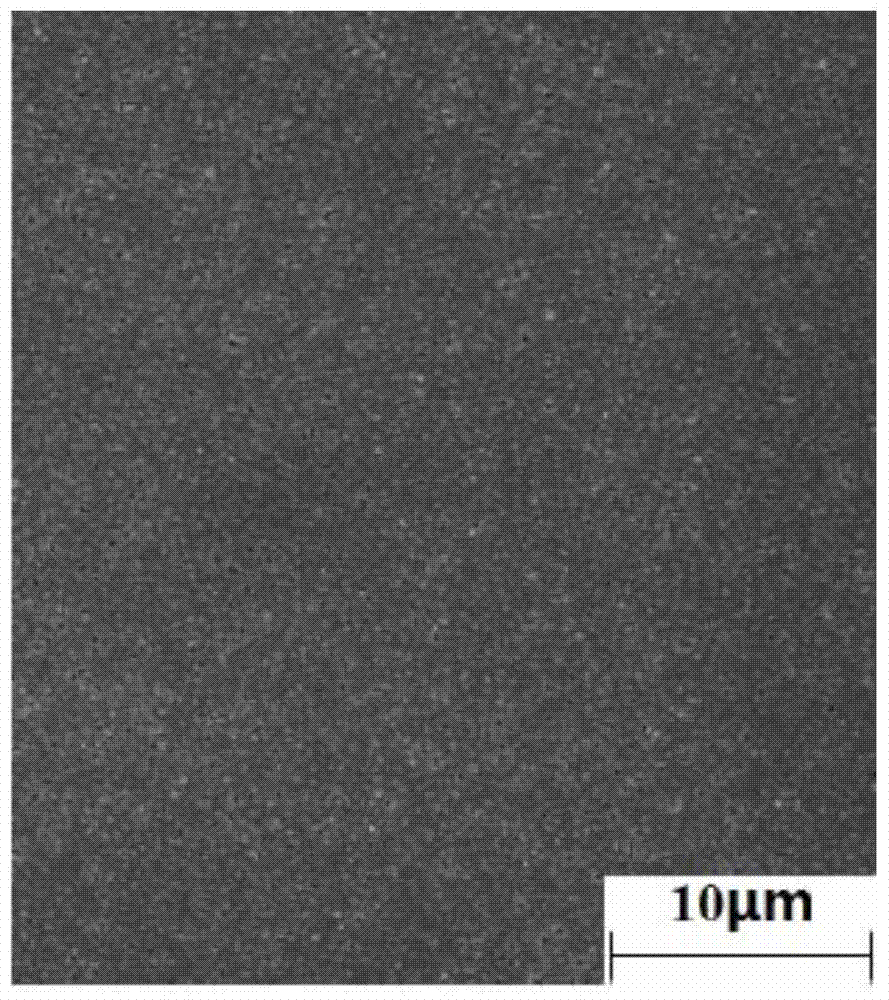

[0020] b) coating the precursor on the substrate to form a precursor film;

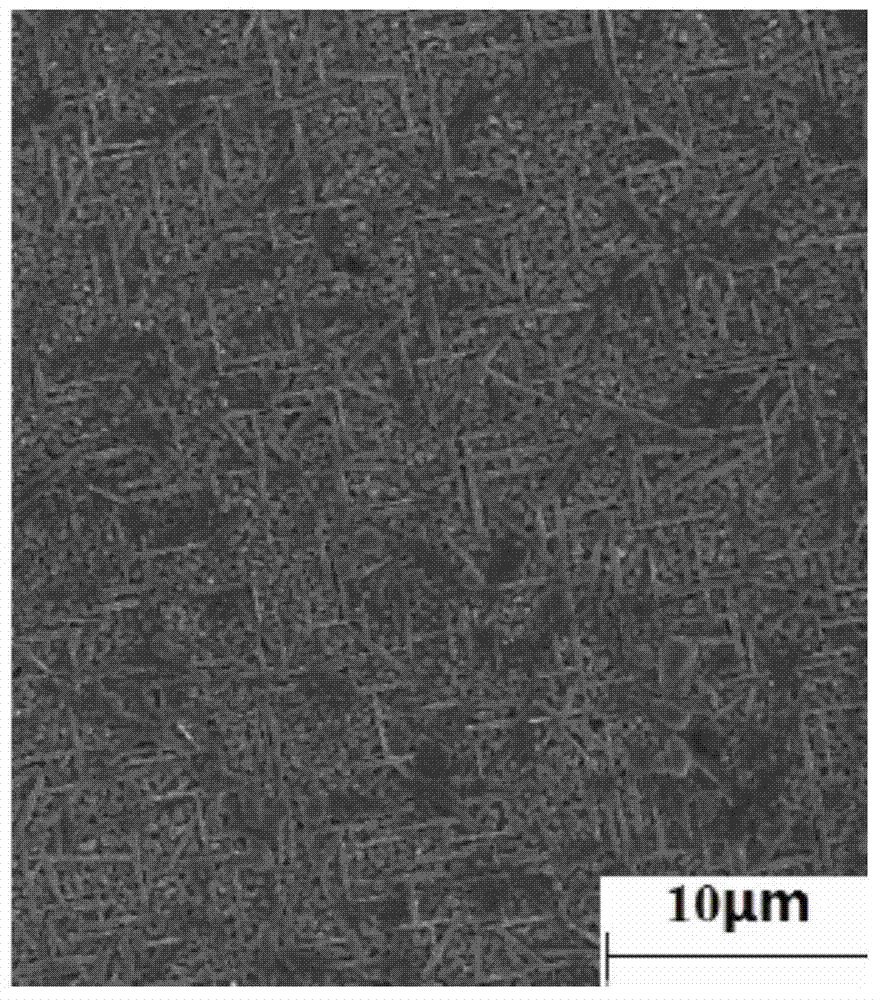

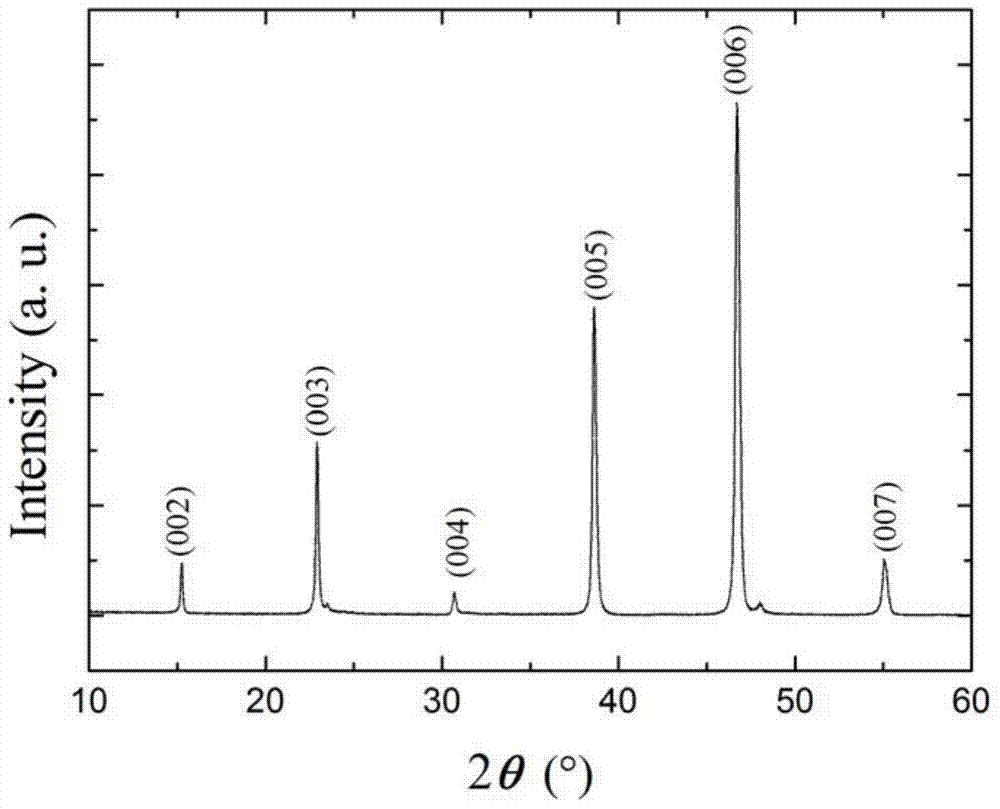

[0021] c) Put the precursor film into a heat treatment furnace, feed a high-purity oxygen flow at a flow rate of 0.1 m / min to 10 m / min as a heat treatment atmosphere, and raise the temperature of the furnace at a rate of 1 °C / min to 1500 °C / min Rise to 300°C-650°C in minutes and keep warm for 0-5 hours, and increase the introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com