PPR pipe having high ageing resistance and manufacturing method thereof

A manufacturing method and aging-resistant technology, applied in the field of PPR pipe and its manufacturing, can solve the problems such as difficult to grasp the dosage and cumbersome process, and achieve the effects of improving anti-aging performance, increasing hardness and low-temperature brittleness, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Select 2 kilograms of PPR (Yanshan Petrochemical PPR powder C4420) and add 200 grams of micron-sized zinc powder, and put it into a high-speed mixer for thorough mixing; add 5 grams of DOP liquid medicine to the uniformly mixed PPR and zinc powder mixture, Put it into a molding machine and heat it to 230°C, keep it warm for 3 minutes to make a gelatinous raw material, put it into a twin-screw extruder to extrude and select pellets, and then use a single-screw pipe extruder for extrusion molding.

Embodiment 2

[0016] Example 2: Select 2 kg of PPR (Yanshan Petrochemical PPR powder C4420) and add 160 g of micron-sized zinc powder, put it into a high-speed mixer and mix it thoroughly; Put it into a molding machine and heat it to 200°C, keep it warm for 1 minute to make a gel-like raw material, put it into a twin-screw extruder to extrude and select pellets, and then use a single-screw pipe extruder to extrude the tube.

Embodiment 3

[0017] Example 3: Select 2 kilograms of PPR (Yanshan Petrochemical PPR powder C4420) and add 180 grams of micron-sized zinc powder, put it into a high-speed mixer for thorough mixing; add 4 grams of DOP syrup to the uniformly mixed PPR and zinc powder mixture, Put it into a molding machine and heat it to 210°C, keep it warm for 2 minutes to make a gelatinous raw material, put it into a twin-screw extruder to extrude and select pellets, and then use a single-screw pipe extruder to extrude the tube.

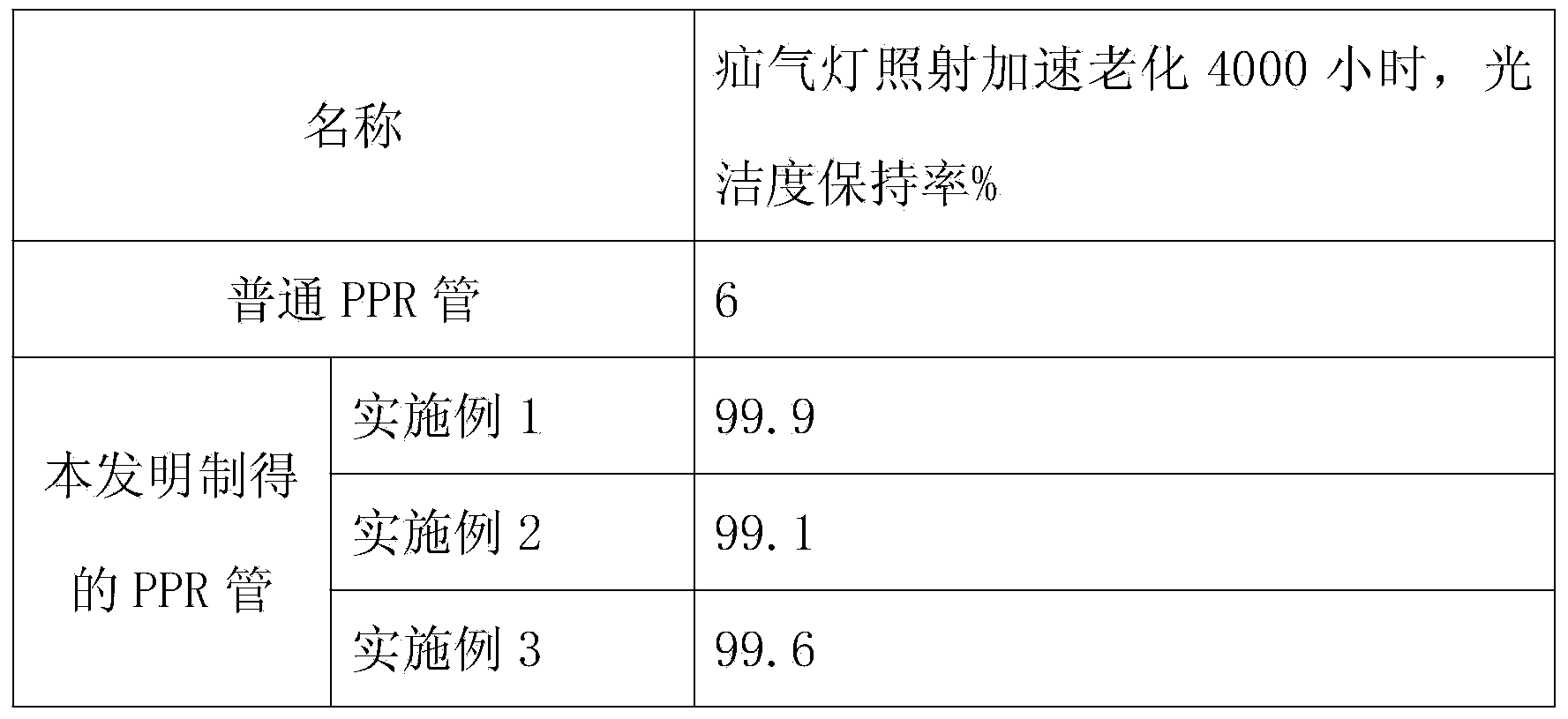

[0018] The anti-aging test of the produced PPR pipe is as follows:

[0019]

[0020] Note: The lower the gloss retention rate, the worse the chalking phenomenon caused by material aging

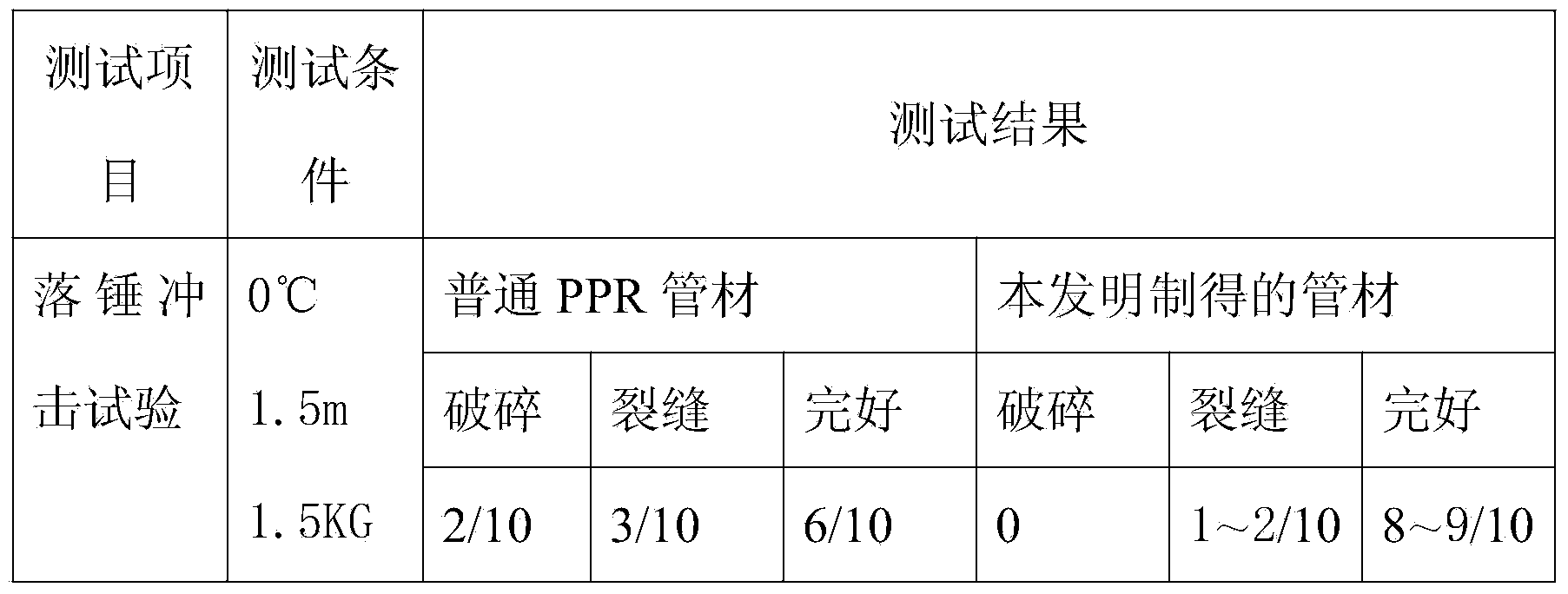

[0021] Low-temperature impact performance test on the manufactured PPR pipe:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com