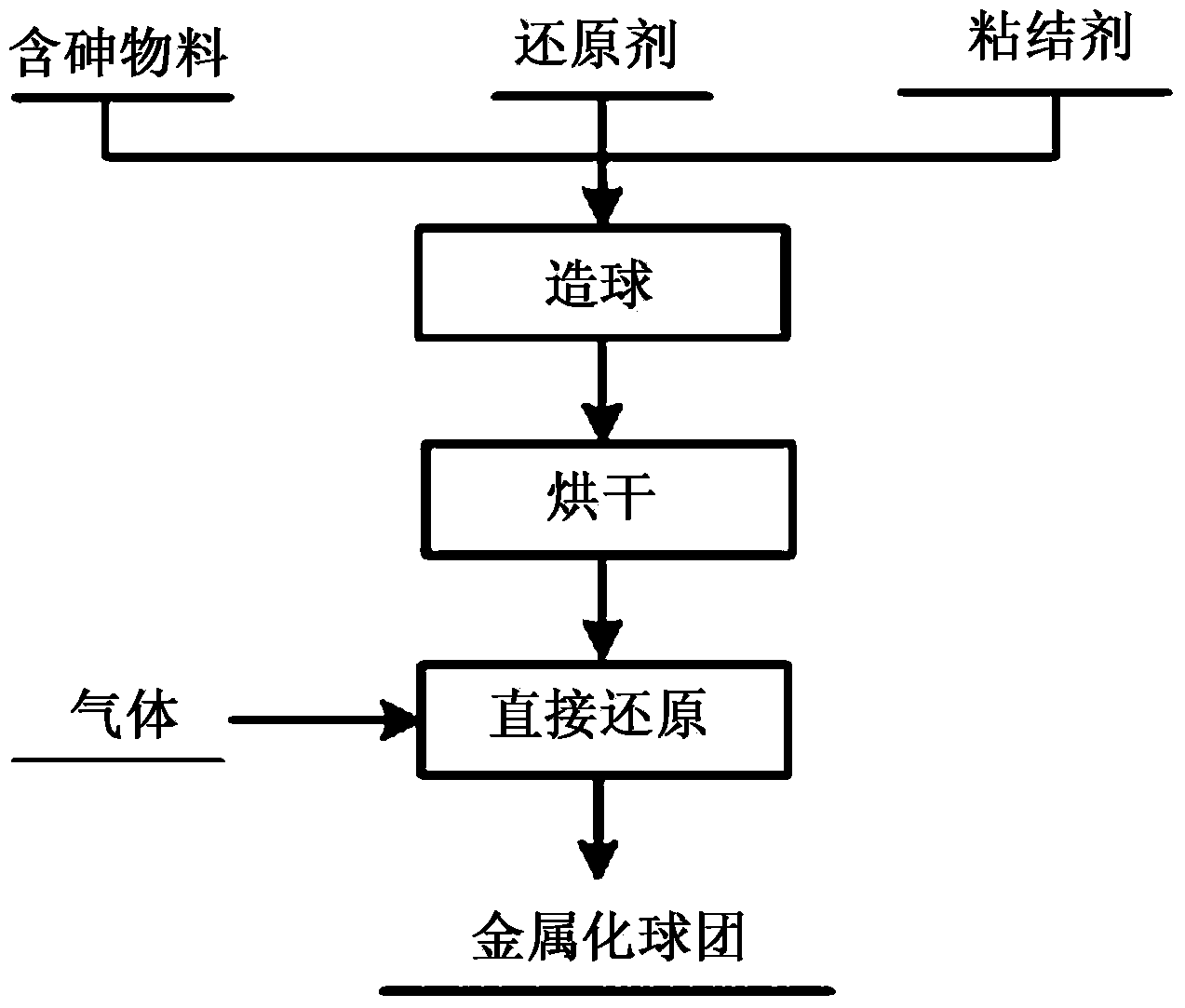

Method of arsenic removal in direct reduction process

A direct, arsenic-removing technology, applied in the direction of improving process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] The arsenic-containing material is high-arsenic iron ore, the weight percentage of TFe is 46.70%, and the weight percentage of As is 0.52%, wherein As is FeAsO 4 form exists. Grind it to make powder, select 100g of high-arsenic iron ore powder below 100 mesh, mix it with 20g of coal powder, add 8% binder to make pellets, and the diameter of the carbon-containing pellets is 1cm-2cm. Place in an oven at 200°C and dry for 4 hours to ensure most of the free water is removed. The dry carbon-containing pellets can be put into the reduction furnace and the furnace temperature rises to 850°C, or they can be put in after the reduction furnace reaches the set temperature of 850°C, and N 2 - CO gas controls the atmosphere in the furnace as a reducing atmosphere, and opens the tail gas treatment device to treat the tail gas discharged from the reduction furnace. After reduction at 850°C for 2 hours, the metallized pellets after direct reduction were taken out, cooled with water t...

example 2

[0043] The arsenic-containing material is low-arsenic iron ore, the weight percentage of TFe is 61.78%, and the weight percentage of As is 0.066%, wherein As exists in the form of FeAsS. Grind it to make powder, select 100g of low-arsenic iron ore powder below 100 mesh, add 20g of coke powder and mix evenly, add 8% binder to make pellets, the diameter of carbon-containing pellets is 1cm-2cm, and the prepared pellets Place in an oven at 200°C and dry for 4 hours to ensure most of the free water is removed. The dry carbon-containing pellets can be put into the reduction furnace and the furnace temperature rises to 1000°C, or they can be put in after the reduction furnace reaches the set temperature of 1000°C, and N 2 -O 2 The gas is to control the atmosphere in the furnace as an oxidizing atmosphere, and the tail gas treatment device is opened to process the tail gas discharged from the reduction furnace. After reduction at 1000°C for 3 hours, the metallized pellets after dire...

example 3

[0050] The arsenic-containing material is arsenic-containing copper slag, in which TFe is 36.10% by weight, Cu is 0.68% by weight, and As content is 0.14%, where Cu exists in the form of CuO, and Fe exists in the form of Fe 2 o 3 Exist in the form, As as As 2 o 5 form exists. Grind it, select 100g of arsenic-containing copper slag powder below 100 mesh, add 30g of petroleum coke, add 8% binder and mix well, and then make pellets. The diameter of the carbon-containing pellets is 1cm-2cm. In an oven at 200°C, dry for 4 hours to ensure that most of the free water is removed. The dry carbon-containing pellets can be put into the reduction furnace and the furnace temperature rises to 1250°C, or it can be put in after the reduction furnace reaches the set temperature of 1250°C, and N 2 - CO gas controls the atmosphere in the furnace as a reducing atmosphere, and opens the tail gas treatment device to treat the tail gas discharged from the reduction furnace. After reduction at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com