Reflecting type LED automotive headlamp

A technology of automobile headlights and reflectors, which is applied in the direction of reflectors, motor vehicles, refractors, etc., can solve the problems of inconvenient shape, complex space occupation, and large space occupation of automobiles, and achieve simple and stable structure and high utilization rate , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

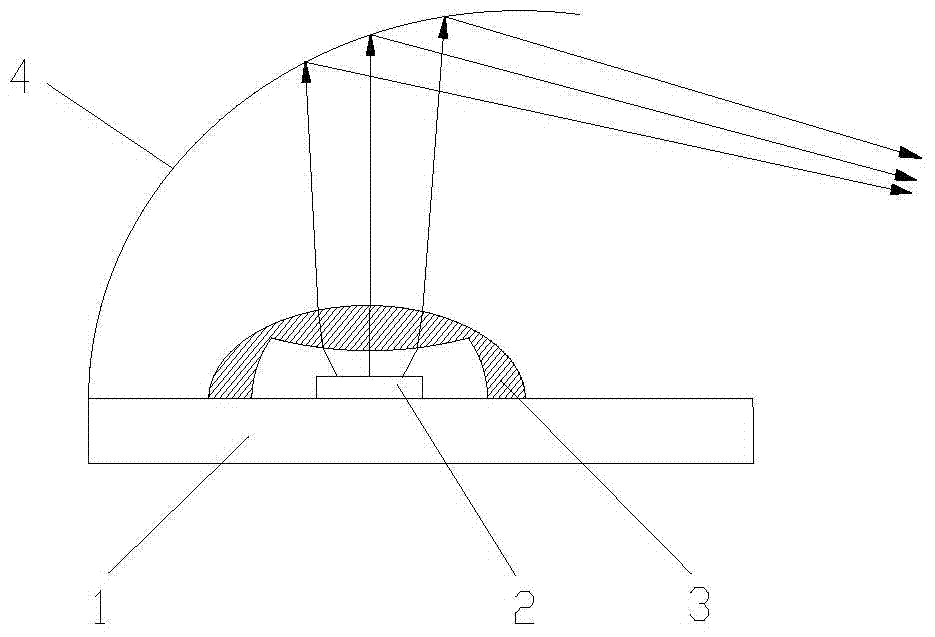

[0024] refer to figure 1 , a reflective LED automotive headlamp, comprising:

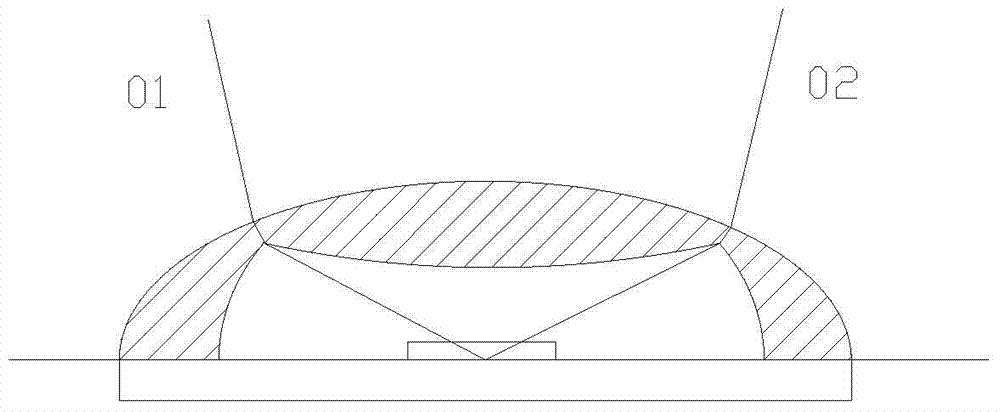

[0025] An aluminum substrate 1, an LED chip 2 mounted on the aluminum substrate, and a focusing lens 3, the focusing lens 3 and the aluminum substrate 1 together surround the LED chip 2;

[0026] It also includes a free-form reflector 4 arranged on the light source path, and the free-form reflector 4 completely reflects the light beam emitted by the LED chip 2 condensed by the focusing lens 3 .

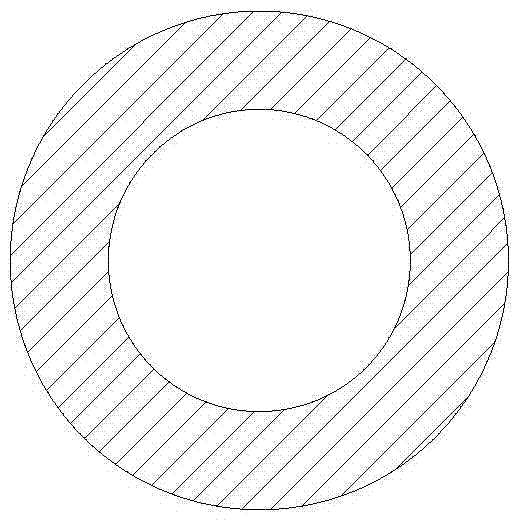

[0027] The area where the light beam passes through the inner surface of the focusing lens 3 is coated with an anti-reflection film, and the peripheral annular area of the focusing lens is coated with black paint. The black paint is used to absorb stray light and prevent l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com