Preparation method of graphene/hemoglobin composite film modified electrode

A technology of hemoglobin and composite thin films, applied in the direction of material electrochemical variables, material analysis by electromagnetic means, measurement devices, etc., can solve the problems of weak interaction, poor dispersion, and restrictions on the research and application of graphene composite materials, and achieve the goal of making The effect of simple process, low cost and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

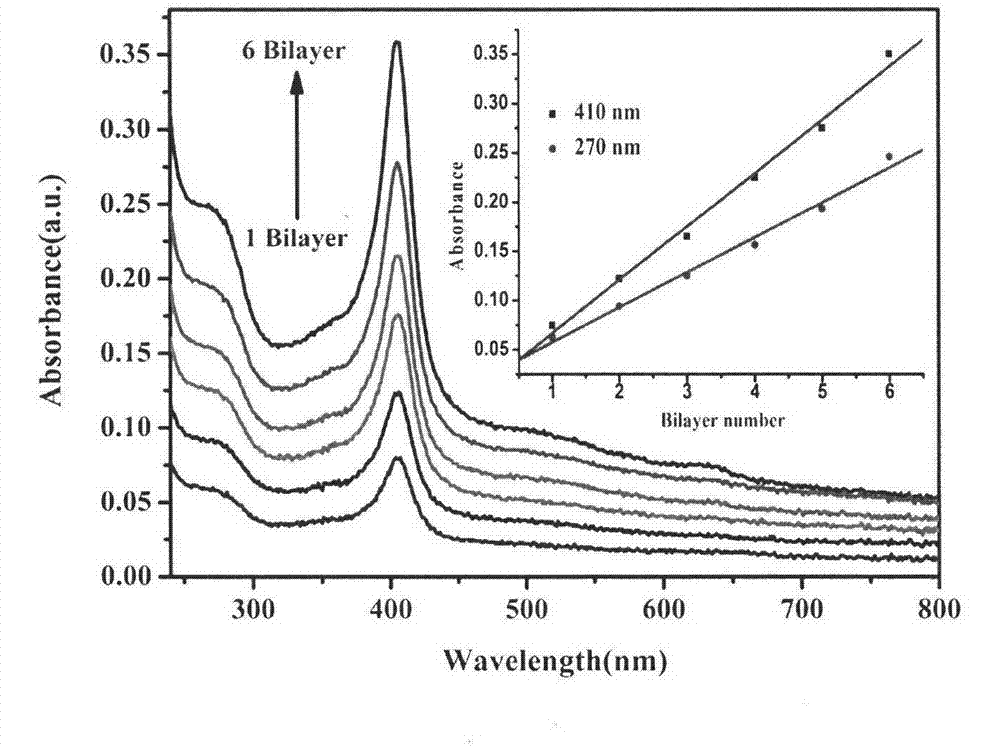

Method used

Image

Examples

Embodiment 1

[0016] In the first step, add 30 mg graphene oxide to a 250 mL flask, add DMF / H 2 O (V:V=9:1) solution 50mL, stirred, sonicated for 30min. Add 0.0248g NaBH to the flask 4 , 80°C oil bath for 4 hours, after cooling to room temperature, 10g of acrylic acid and 40mL of H 2 O, stirred for 30min. into high-purity N 2 30min, slowly drop 100mg (NH 4 ) 2 S 2 o 8 (dissolved in 80mL deionized water), ultrasonic, 60°C oil bath, stirring. After 48h, cool to room temperature and wash with 200mLH 2 After diluting with O, sonicate for 1 h and centrifuge to obtain polyacrylic acid-modified graphene.

[0017] In the second step, 20 mg of hemoglobin was dissolved in 10 mL of water to obtain a 2 mg / mL aqueous hemoglobin solution.

[0018] In the third step, the treated glassy carbon electrode is soaked in the hemoglobin aqueous solution for 20 minutes, then rinsed with a large amount of deionized water, and dried with nitrogen gas, so that the surface of the obtained glassy carbon elec...

Embodiment 2

[0022] In the first step, add 50 mg graphene oxide to a 250 mL flask, add DMF / H 2 O (V:V=9:1) solution 80mL, stirred, sonicated for 30min. Add 0.0248g NaBH to the flask 4 , 80°C oil bath for 4 hours, after cooling to room temperature, 20g of benzenesulfonic acid and 60mL of H 2 O, stir for 30min. into high-purity N 2 30min, slowly dropwise add 0.2g (NH 4 ) 2 S 2 o 8 , ultrasonic, 60 ° C oil bath, stirring. After 48h, cool to room temperature and wash with 300mL H 2 After diluting with O, sonicate for 1 h, and centrifuge to obtain polybenzenesulfonic acid-modified graphene.

[0023] In the second step, 10 mg hemoglobin was dissolved in 10 mL water to obtain a 1 mg / mL hemoglobin aqueous solution.

[0024] In the third step, the treated gold electrode is soaked in the hemoglobin aqueous solution for 20 minutes, then rinsed with a large amount of deionized water, and dried with nitrogen gas, so that the surface of the obtained gold electrode is positively charged.

[00...

Embodiment 3

[0028] In the first step, add 50 mg graphene oxide to a 250 mL flask, add DMF / H 2 O (V:V=9:1) solution 80mL, stirred, sonicated for 30min. Add 0.0248g NaBH to the flask 4 , 80°C oil bath for 4 hours, after cooling to room temperature, 20g of acrylic acid and 60mL of H 2 O, stirred for 30min. into high-purity N 2 30min, slowly dropwise add 0.2g (NH 4 ) 2 S 2 o 8 , ultrasonic, 60 ° C oil bath, stirring. After 48h, cool to room temperature and wash with 300mLH 2 After diluting with O, sonicate for 1 h, and centrifuge to obtain polybenzenesulfonic acid-modified graphene.

[0029] In the second step, 10 mg hemoglobin was dissolved in 10 mL water to obtain a 1 mg / mL hemoglobin aqueous solution.

[0030] In the third step, soak the treated ITO electrode in the hemoglobin aqueous solution for 30 minutes, then rinse it with a large amount of deionized water, and dry it with nitrogen gas, so that the surface of the obtained ITO electrode is positively charged.

[0031] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com