Method for preparing graphene/polyaniline laminated films on basis of layer-by-layer self-assembly technique

A layer-by-layer self-assembly and composite film technology, which is applied in the field of composite material preparation, can solve problems such as cumbersome methods, structure, and performance impact, and achieve the effects of low technical cost, mild conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

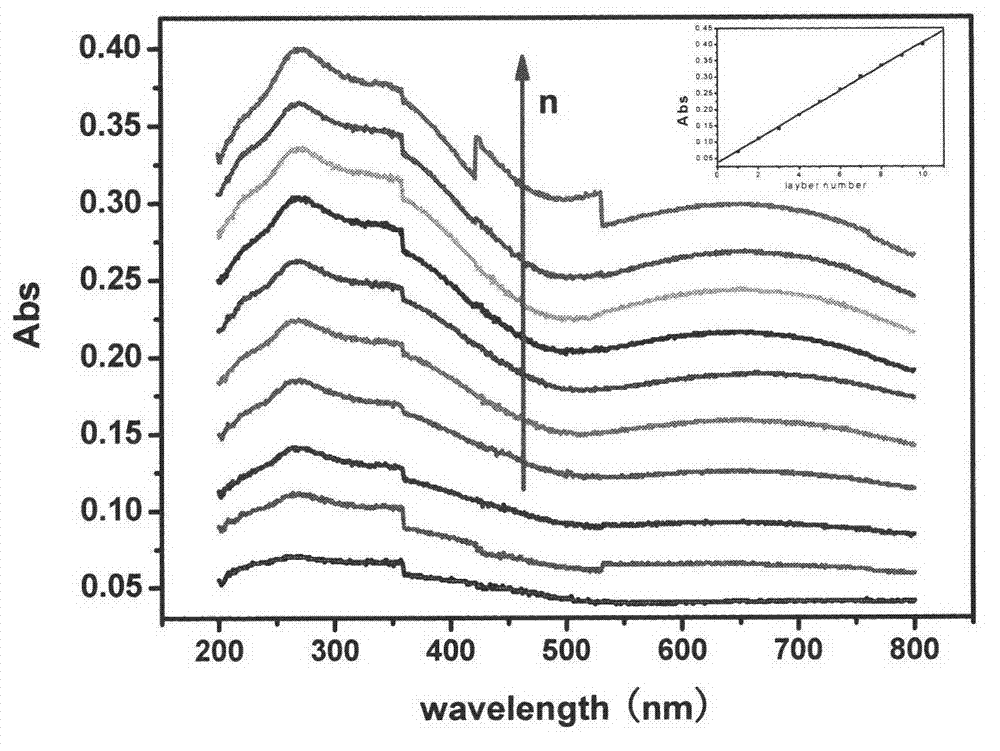

Method used

Image

Examples

Embodiment 1

[0017] In the first step, 10 mg of graphene oxide was suspended and dispersed in 20 mL of ultrapure water. Ultrasonic dispersion was performed for 30 min (S45D, 500 W, 30% amplitude) to obtain a brown GO dispersion. The resulting dispersion was mixed with 20 ml of ultrapure water, 1 mL of hydrazine hydrate solution (85% mass fraction), and 70-145 μL ammonia water (30% mass fraction) in a 100 mL flask. After shaking vigorously or stirring for a few minutes, the container was placed in a water bath at 95°C for 60 min. The reaction solution was dialyzed in 0.5 wt% ammonia water to remove excess hydrazine in the remaining dispersion to obtain 0.25 mg / mL surface with Carboxylated graphene dispersion.

[0018] The second step, preparation of polyaniline aqueous solution Dissolve dark green aniline in DMAC (dimethylacetamide) to prepare a 120 mg / mL solution, stir for 48 h, and then sonicate for 8-10 h. The prepared solution was filtered through a 0.75 μm membrane filter to remove so...

Embodiment 2

[0023] The first step is to suspend and disperse 10mg graphene oxide in 20mL ultrapure water for 30min, and use 5wt% Na 2 CO 3 The solution adjusts the pH of the graphene oxide solution to 9-10, then adds sodium borohydride solution, and reacts at 80° C. for 1 h. Centrifugal washing several times, redispersed in water after ultrasonic oscillation to obtain pre-reduced graphene oxide. Under ice bath conditions (0-5°C), mix 460mg of p-aminobenzenesulfonic acid and 0.66g of 1M ice HCl solution, add an appropriate amount of ice water to dissolve it completely, and then slowly add 15% NaNO 2 solution. Add the prepared aryl diazonium salt dropwise to the pre-reduced graphene oxide solution prepared in the first step, and react in an ice bath for 2 h. Centrifuge and wash several times, and redisperse in water after ultrasonic oscillation. Then add hydrazine hydrate to it, and react at 100°C for 24h. After several times of centrifugal washing, disperse in water, and adjust the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com