Aluminum paste tank self-cleaning device

A self-cleaning, aluminum-silver paste technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of failing to meet the requirements of the production process, high labor intensity, and large input of manpower, and achieve Ideal treatment effect, improved production efficiency, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

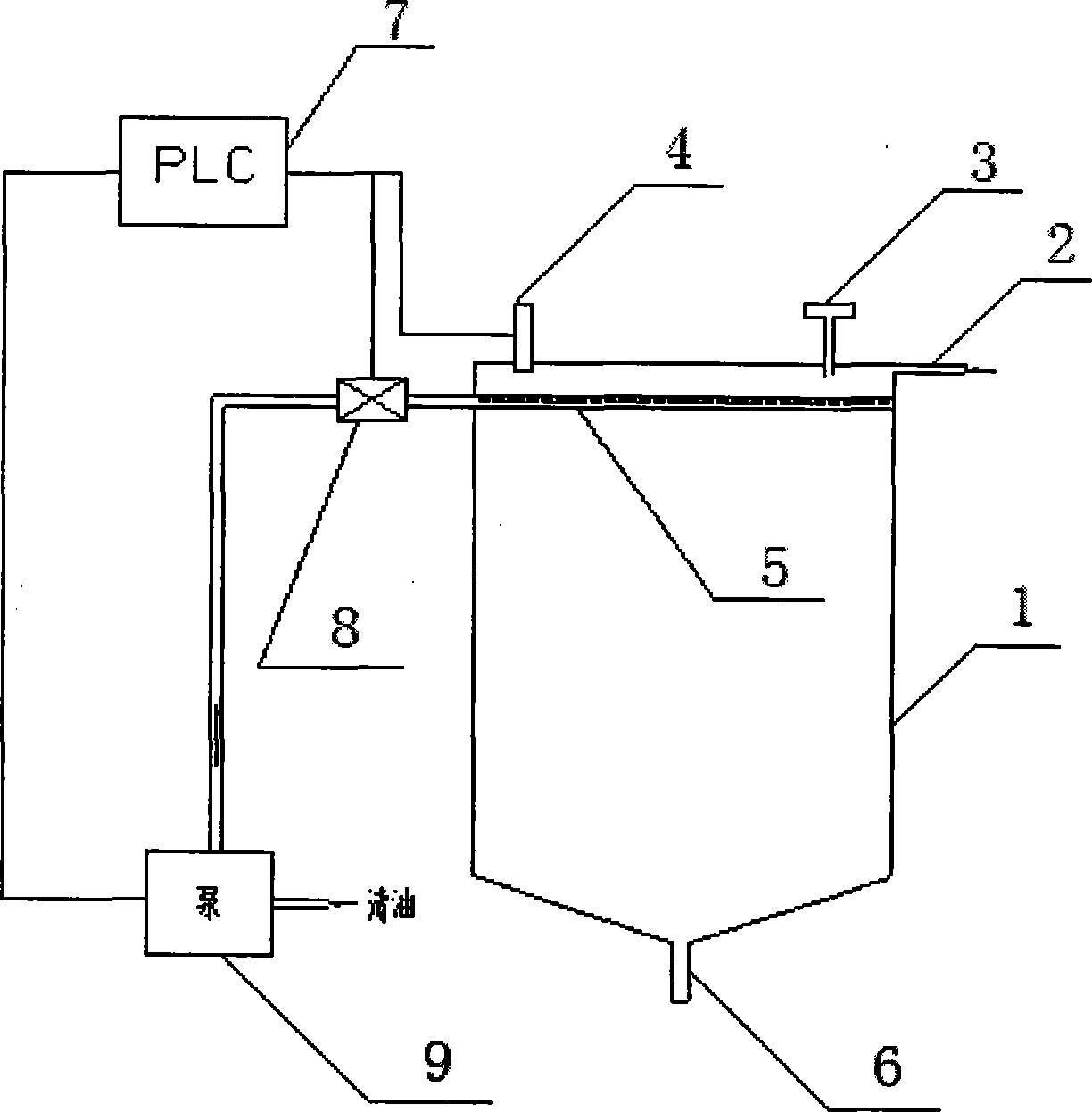

[0017] like figure 1 , 2 The self-cleaning device for a material tank for aluminum-silver paste includes a material tank 1, a feed pipe 2 installed on the material tank, a fire-stop cover 3, an ultrasonic liquid level gauge 4, an annular fuel injection pipe 5, a discharge The pipe 6 and the gear pump 9, electromagnetic valve 8, and controller 7 installed outside the material tank; the controller 7 is electrically connected to the ultrasonic liquid level gauge 4, the gear pump 9, and the electromagnetic valve 8, and receives the detection of the ultrasonic liquid level gauge 4 information, and control the switch of solenoid valve 8 and the working state of gear pump 9; 1, the annular fuel injection pipe 5 is installed on the top of the material tank 1, below the feed pipe 2, and the discharge pipe 6 is installed on the bottom of the material tank 1.

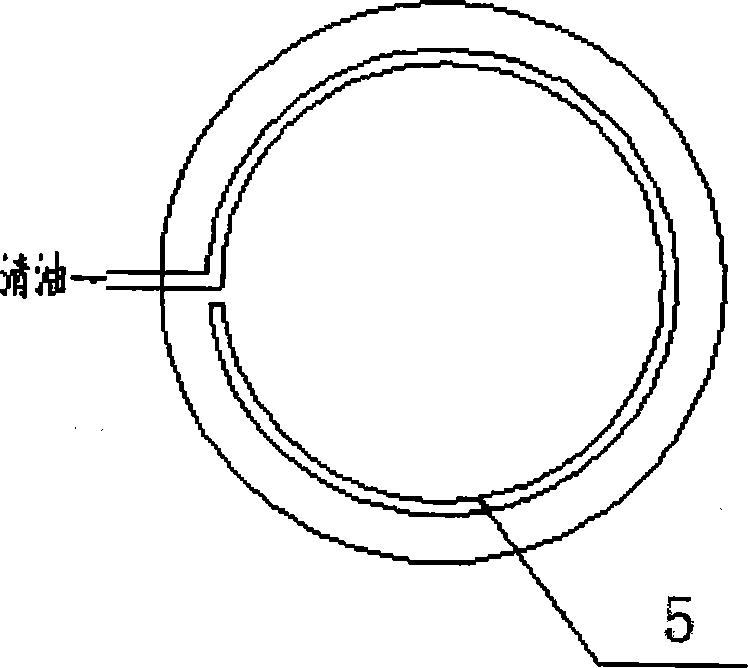

[0018] Further, the annular fuel injection pipe 5 is bent from a DN20 galvanized pipe into a spiral annular pipeline, and thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap