Reinforced and toughened anti-bacterial polypropylene composition and preparation method thereof

An antibacterial polypropylene, strengthening and toughening technology, which is applied in the field of reinforced and toughened antibacterial polypropylene composition and its preparation, can solve the problems not related to the mechanical properties and antibacterial properties of polypropylene, achieve rapid antibacterial, broaden the application range, and improve mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

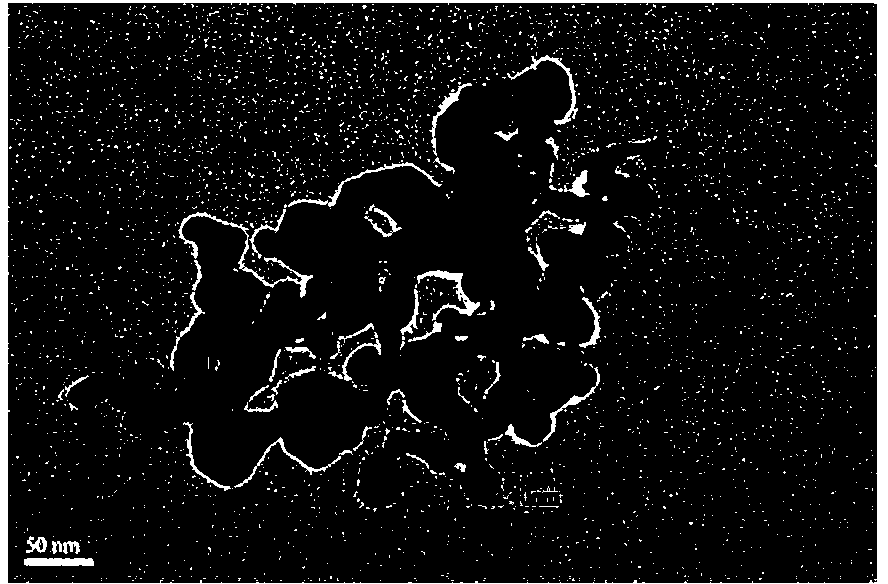

Image

Examples

Embodiment 1

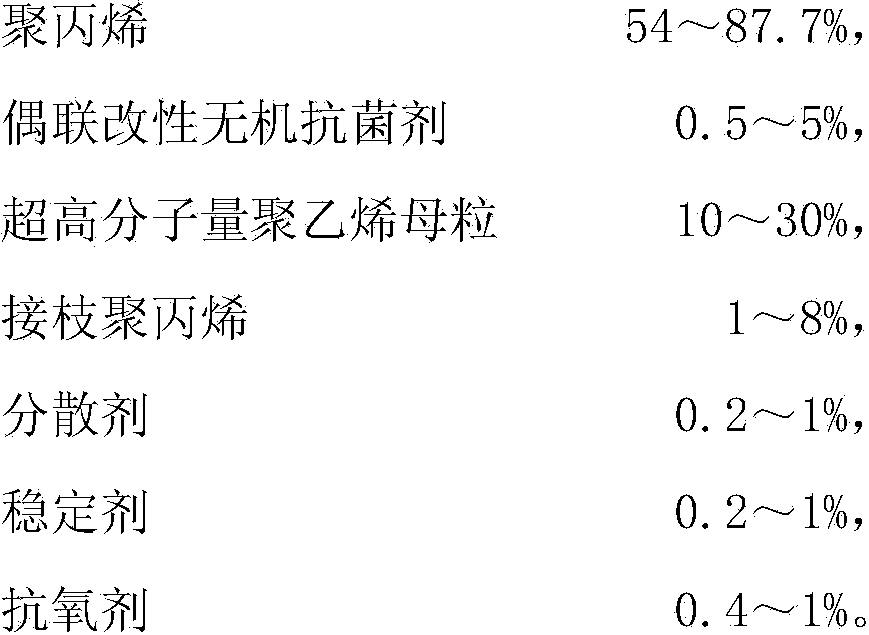

[0039] This embodiment relates to a reinforced and toughened antibacterial polypropylene composition, including the following components: polypropylene, coupled modified inorganic antibacterial agent, ultra-high molecular weight polyethylene masterbatch, grafted polypropylene, dispersant, stabilizer , Antioxidant; Among them, the ultra-high molecular weight polyethylene masterbatch is composed of the following components: ultra-high molecular weight polyethylene, linear low density polyethylene, inorganic powder, compatibilizer.

[0040] The preparation method of the reinforced and toughened antibacterial polypropylene composition of this embodiment includes the following steps:

[0041] 1) Surface modification of inorganic antibacterial agents

[0042] Heat to 60°C with ethanol as the dispersion medium, add silane coupling agent KH550 and disperse for 5 minutes, then add inorganic antibacterial agent zinc oxide for 30 minutes, dry, grind, and siev to obtain modified zinc oxide, wher...

Embodiment 2

[0048] This embodiment relates to a reinforced and toughened antibacterial polypropylene composition, including the following components: polypropylene, coupled modified inorganic antibacterial agent, ultra-high molecular weight polyethylene masterbatch, grafted polypropylene, dispersant, stabilizer , Antioxidant; Among them, the ultra-high molecular weight polyethylene masterbatch is composed of the following components: ultra-high molecular weight polyethylene, linear low density polyethylene, inorganic powder, compatibilizer.

[0049] The preparation method of the reinforced and toughened antibacterial polypropylene composition of this embodiment includes the following steps:

[0050] 1) Surface modification of inorganic antibacterial agents

[0051] Heat to 60°C with ethanol as the dispersion medium, add silane coupling agent KH550 and disperse for 5 minutes, then add inorganic antibacterial agent zinc oxide for 30 minutes, dry, grind, and siev to obtain modified zinc oxide, wher...

Embodiment 3

[0057] This embodiment relates to a reinforced and toughened antibacterial polypropylene composition, including the following components: polypropylene, coupled modified inorganic antibacterial agent, ultra-high molecular weight polyethylene masterbatch, grafted polypropylene, dispersant, stabilizer , Antioxidant; Among them, the ultra-high molecular weight polyethylene masterbatch is composed of the following components: ultra-high molecular weight polyethylene, linear low density polyethylene, inorganic powder, compatibilizer.

[0058] The preparation method of the reinforced and toughened antibacterial polypropylene composition of this embodiment includes the following steps:

[0059] 1) Surface modification of inorganic antibacterial agents

[0060] Heat to 70℃ with isopropanol as the dispersion medium, add silane coupling agent DL602 and disperse for 5 minutes, then add inorganic antibacterial agent zinc oxide to disperse for 30 minutes, dry, grind, and siev to obtain modified z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com