Comprehensive recycling treatment method of waste rare-earth fluorescent lamp

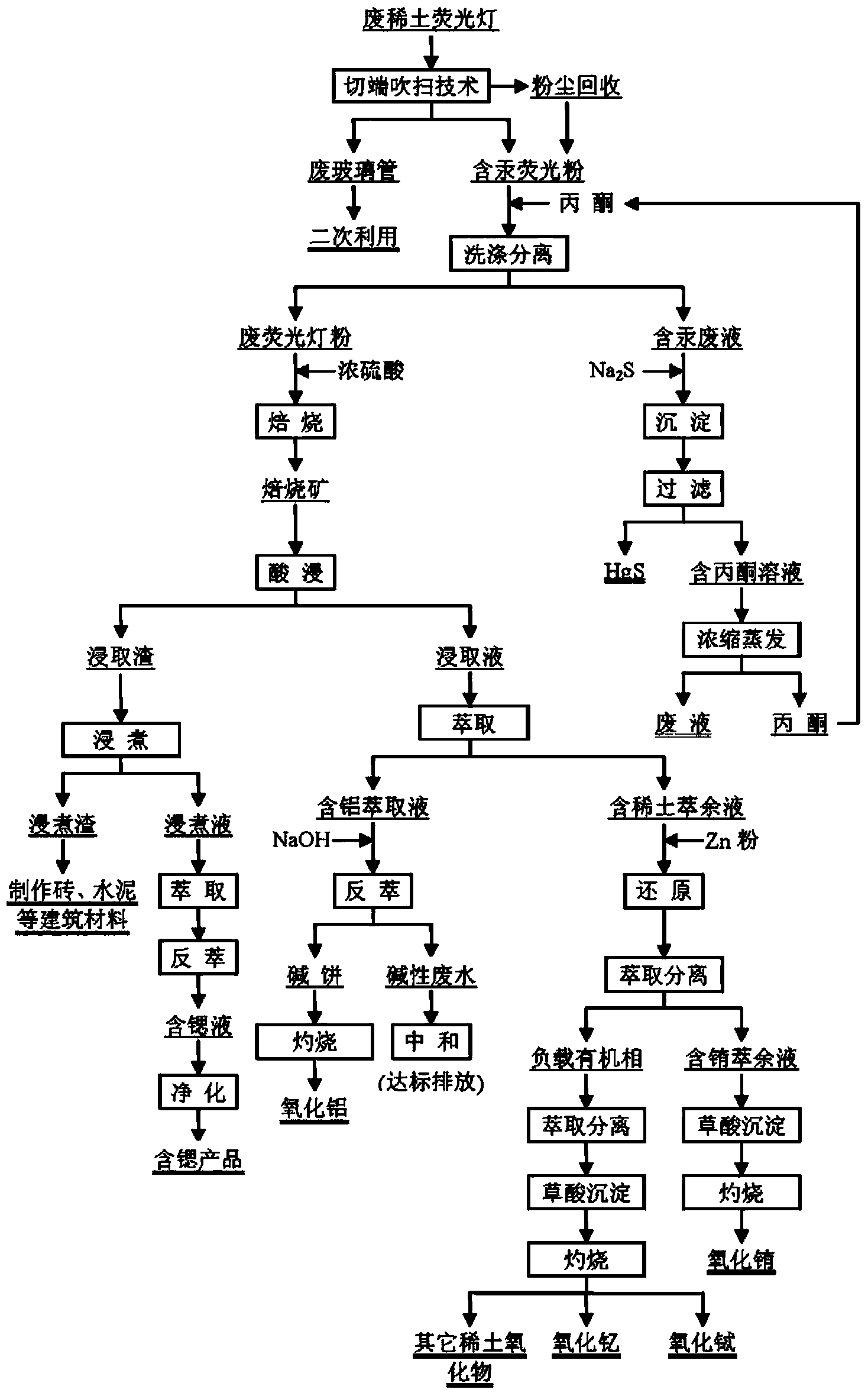

A technology for recycling and processing fluorescent lamps, applied in the direction of improving process efficiency, etc., can solve the problems of comprehensive recycling and processing of waste rare earth fluorescent lamps, etc., and achieve the effect of low recycling cost and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The following steps are adopted to comprehensively recover valuable elements rare earth, aluminum, strontium and mercury from waste rare earth fluorescent lamps.

[0035] 1) Take four 15W waste rare earth fluorescent lamps, each weighing about 60g, containing 23g of glass, and 10mg of mercury per lamp. The mercury-containing phosphor in the waste rare earth fluorescent lamp is separated from the glass tube by using the incisal purge technology, and an acetone solution with a mass percentage concentration of 20% is added to the separated mercury-containing phosphor. The liquid-solid ratio of acetone to the mercury-containing phosphor is: 4:1, sonicate for 0.5 hour at an ultrasonic frequency of 30kHz to obtain 600ml mercury-containing waste liquid. After testing, the mercury content in the mercury-containing waste liquid is 61.66mg / L, and the calculated mercury content is 37mg. The calculated mercury removal rate after ultrasonic separation is as high as 92.50%.

[0036]...

Embodiment 2

[0045] The waste rare earth fluorescent lamp used in the experiment is the same as that in Example 1, and the valuable elements rare earth, aluminum, strontium and mercury are comprehensively recovered from it according to the following steps.

[0046]1) Take four 15W waste rare earth fluorescent lamps, each weighing about 60g, containing 23g of glass, and 10mg of mercury per lamp. Use cut-end purge technology to separate mercury-containing phosphors from waste rare earth fluorescent lamps from glass tubes, add acetone solution with a mass percentage concentration of 10% to the separated mercury-containing phosphors, and the liquid-solid ratio of acetone solution to mercury-containing phosphors The ratio is 3:1, sonicate for 0.5 hour at an ultrasonic frequency of 20kHz to obtain 450ml of mercury-containing waste liquid. The mercury content in the mercury-containing waste liquid is 75.55 mg / L, and the calculated mercury content is 34 mg. The calculated mercury removal rate afte...

Embodiment 3

[0056] The waste rare earth fluorescent lamp used in the experiment is the same as that in Example 1, and the valuable elements rare earth, aluminum, strontium and mercury are comprehensively recovered from it according to the following steps.

[0057] 1) Take four 15W waste rare earth fluorescent lamps, each weighing about 60g, containing 23g of glass, and 10mg of mercury per lamp. Use cut-end purge technology to separate mercury-containing phosphors from waste rare earth fluorescent lamps from glass tubes, add acetone solution with a mass percentage concentration of 40% to the separated mercury-containing phosphors, and the liquid-solid ratio of acetone solution to mercury-containing phosphors The ratio is 5:1, and the ultrasonic frequency is 40kHz for 1 hour to obtain 750ml of mercury-containing waste liquid. The mercury content in the mercury-containing waste liquid is 52.00 mg / L, and the calculated mercury content is 39 mg. The calculated mercury removal rate after ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com