Separation and detection method for roflumilast and intermediate thereof

A technology for roflumilast and intermediates, which is applied in the field of separation and detection of roflumilast and its intermediates, and can solve problems such as difficulty in simultaneous separation and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

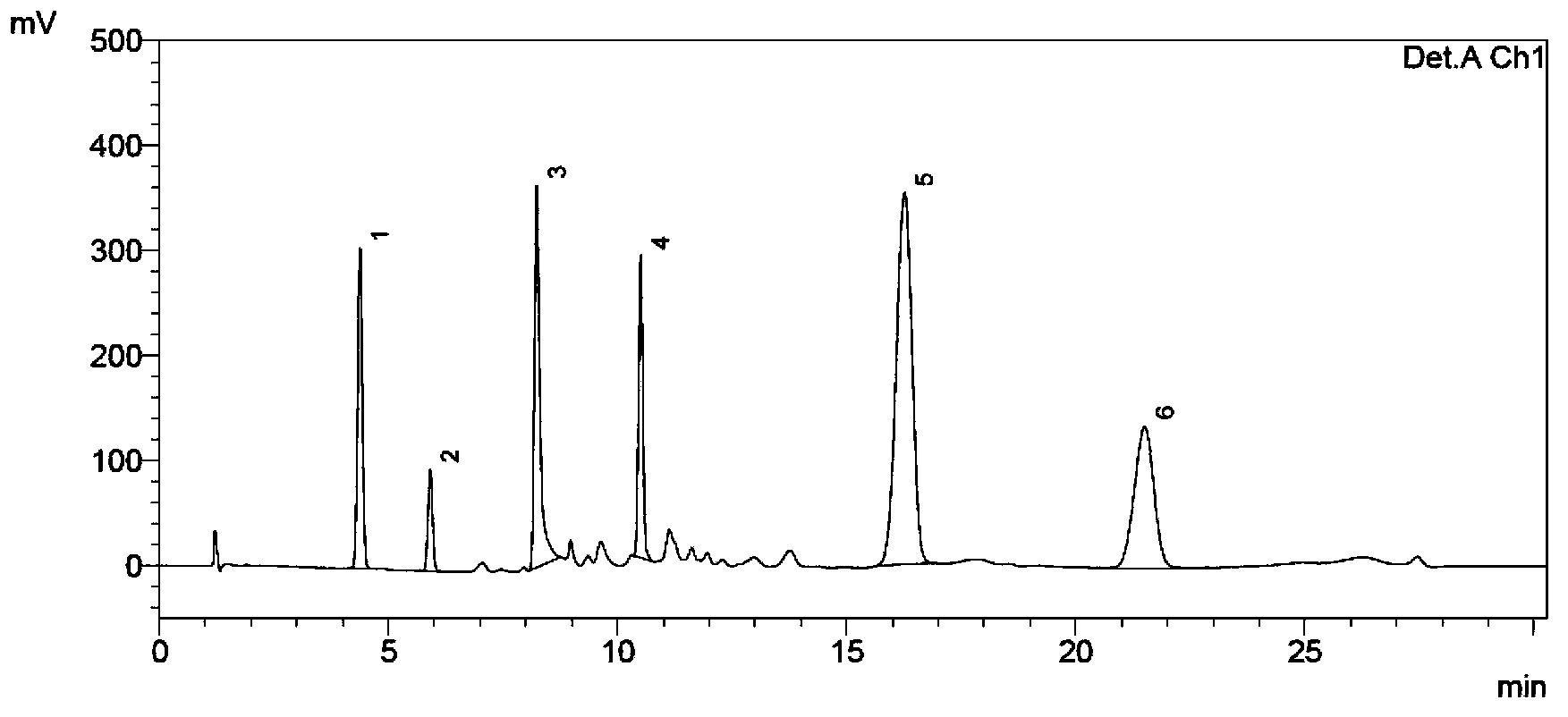

Embodiment 1

[0058] 1) Instruments and conditions

[0059] High-performance liquid chromatography: Shimadzu LC-2010AHT; filler: C18 (150mm×4.6mm, 5μm); mobile phase A: take 1.6g of sodium dihydrogen phosphate and 1.2g of sodium decanesulfonate, add 1000ml of water to dissolve, and use Adjust the pH value to 2.5 with phosphoric acid, mobile phase B: methanol; adopt linear gradient elution method; gradient elution method is as follows:

[0060] time (min)

Mobile phase A%

0

80%

8

40%

25

40%

25.01

80%

40

80%

[0061] The column temperature is 30°C; the flow rate is 1.0ml / min; the detection wavelength is 215nm; the injection volume is 10μl.

[0062] 2) Experimental steps

[0063] Take 25mg each of roflumilast and its intermediates, accurately weigh them, put them in the same 50ml measuring bottle, add methanol to dissolve and dilute to the mark, shake well, and use it as a mixed solution. Carry out...

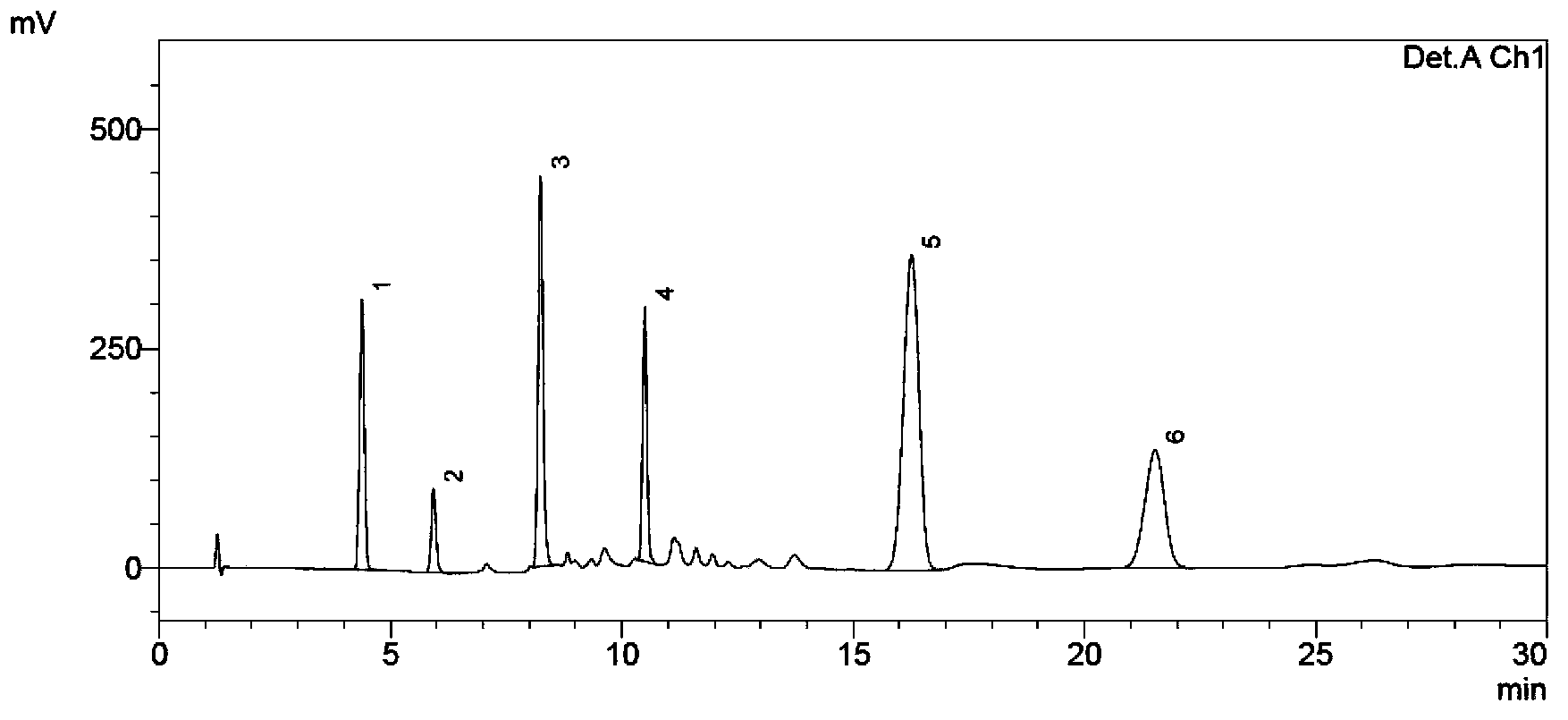

Embodiment 2

[0065] 1) Instruments and conditions

[0066] High-performance liquid chromatography: Shimadzu LC-2010AHT; filler: C18 (150mm×4.6mm, 5μm); mobile phase A: take 1.6g of potassium dihydrogen phosphate, 2.0g of sodium heptanesulfonate, add 1000ml of water to dissolve, and use Adjust the pH value to 2.0 with phosphoric acid, mobile phase B: methanol; adopt linear gradient elution method; gradient elution method is as follows:

[0067] time (min)

Mobile phase A%

0

80%

8

40%

25

40%

25.01

80%

40

80%

[0068] The column temperature is 35°C; the flow rate is 1.0ml / min; the detection wavelength is 215nm; the injection volume is 10μl.

[0069] 2) Experimental steps

[0070] Take 25mg each of roflumilast and its intermediates, accurately weigh them, put them in the same 50ml measuring bottle, add methanol to dissolve and dilute to the mark, shake well, and use it as a mixed solution. Carry ou...

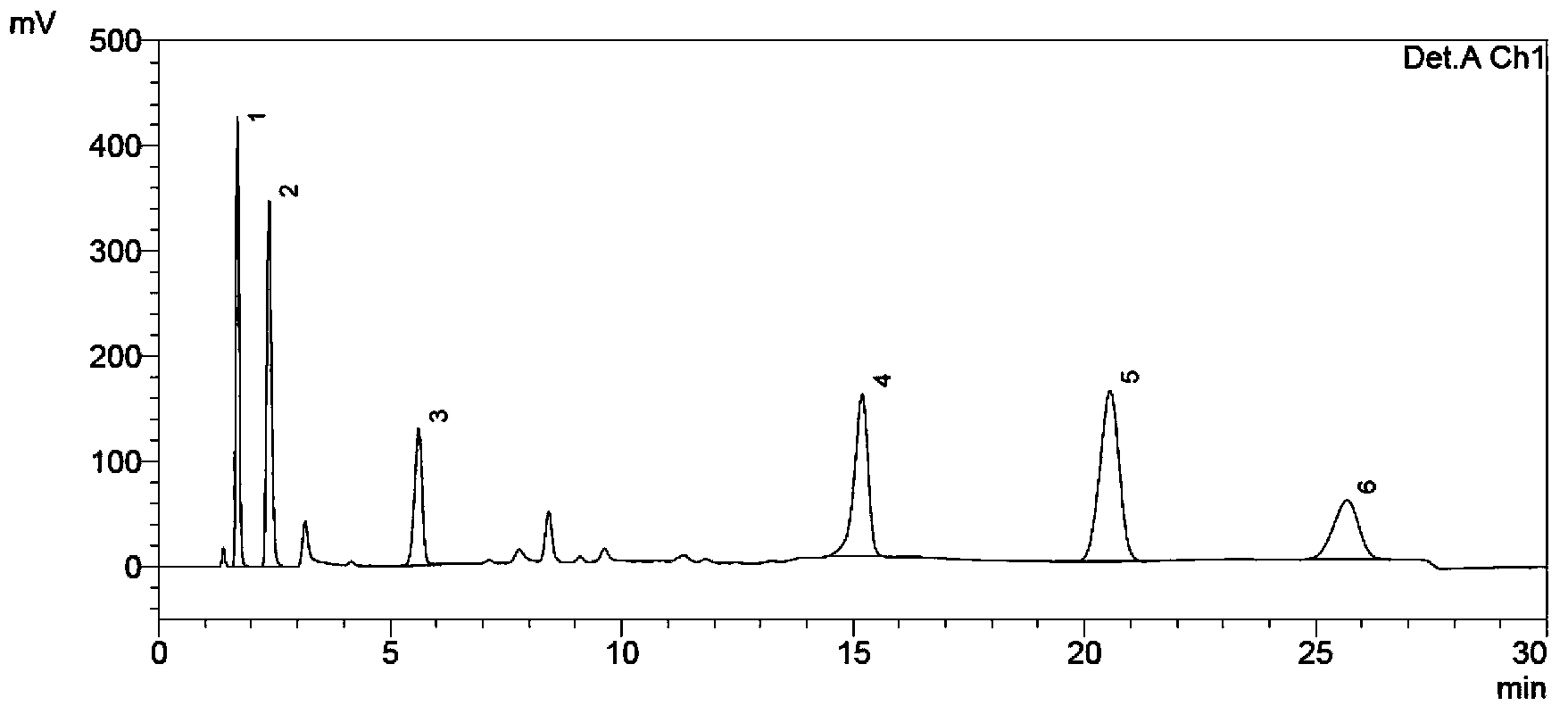

Embodiment 3

[0072] 1) Instruments and conditions

[0073] High-performance liquid chromatography: Shimadzu LC-2010AHT; filler: C18 (150mm×4.6mm, 5μm); mobile phase A: take 0.8g disodium hydrogen phosphate, 0.2g sodium octane sulfonate, add water 1000ml to dissolve, and use Adjust the pH value to 3.0 with phosphoric acid, mobile phase B: methanol; adopt linear gradient elution method; gradient elution method is as follows:

[0074] time (min)

Mobile phase A%

[0075] 0

60%

8

40%

25

40%

25.01

60%

40

60%

[0076] The column temperature is 25°C; the flow rate is 1.0ml / min; the detection wavelength is 215nm; the injection volume is 10μl.

[0077] 2) Experimental steps

[0078] Take 15mg of roflumilast and its intermediates, weigh them accurately, put them in the same 50ml measuring bottle, add methanol to dissolve and dilute to the mark, shake well, and use it as a mixed solution. Carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com