Continuous resistance wire probe and making method thereof

A manufacturing method and resistance wire technology, which are applied to devices using electric/magnetic methods, devices that measure the time required to move a certain distance, etc., can solve problems such as short circuits, improve reliability, simplify the test process, and improve the reliability of the test process. volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

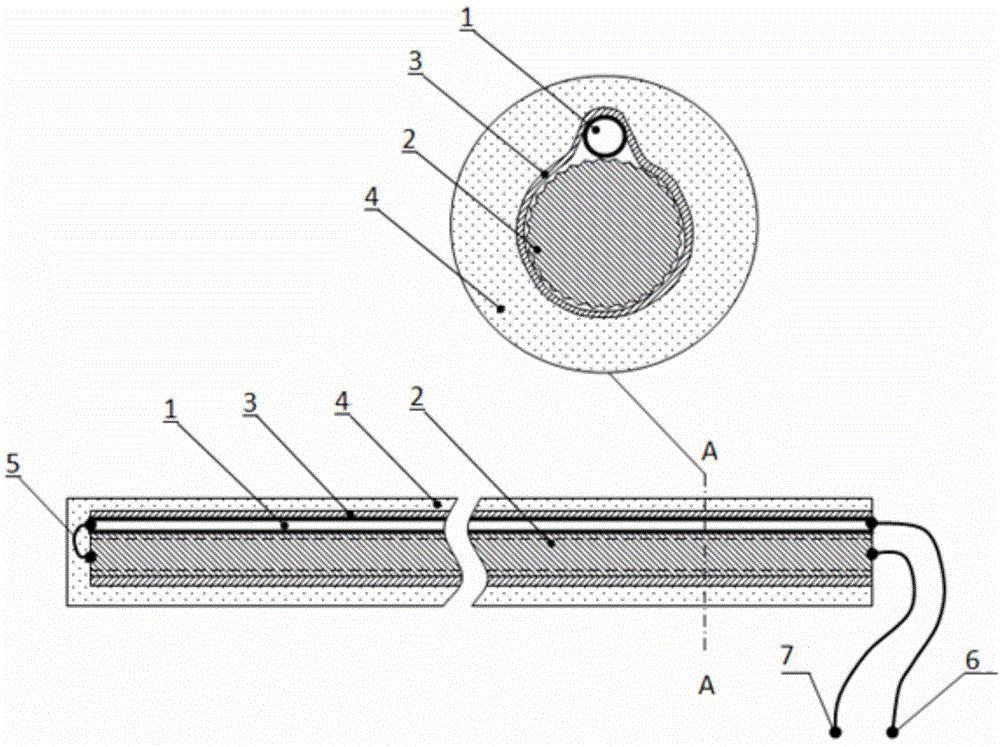

[0030]Take a circular stainless steel wire rope with a diameter of 0.5mm and a length of 0.9m as the twist-shaped metal wire 2; take a constantan polyester enameled wire with a diameter of 0.05mm and a length of 1m as the enamelled resistance wire 1, and measure its resistance value ρ=245.0 Ω / m; Take copper foil with a thickness of 0.015mm as the shielding layer 3, and extrude it into a wire with a diameter of 1.5mm; take a polyvinyl chloride heat shrinkable sleeve with a length of 0.9m as the insulating shell layer 4.

[0031] ①Remove the insulating paint from both ends of the enamelled resistance wire 1 by 10mm, weld the first end to the first end of the twisted metal wire 2 as the conduction terminal 5, the end of the resistance wire as the lead terminal A6, and the end of the twisted metal wire 2 as the lead terminal B7 ;

[0032] ② Wind the enamelled resistance wire 1 and the twist-shaped metal wire 2 together with a winding machine;

[0033] ③ Wrap the shielding layer 3...

Embodiment 2

[0041] Take a stainless steel square steel wire with a side length of 0.3mm and a length of 0.9m as the core wire; take a constantan polyester enameled wire with a diameter of 0.05mm and a length of 1m as the enamelled resistance wire 1, and measure its resistance value ρ=245.0Ω / m; Copper foil with a thickness of 0.015mm is used as the shielding layer 3, and a polyvinyl chloride heat-shrinkable sleeve with a length of 0.9m is used as the insulating shell layer 4.

[0042] ① Vacuum annealing and twisting of stainless steel square steel wire to make twist-shaped metal wire 2 with a pitch of 0.25mm, degreasing and pickling.

[0043] ②Remove 10mm of insulating varnish from both ends of the enamelled resistance wire 1, and weld the first end with the twist-shaped metal wire 2 as the conduction terminal 5, the end of the resistance wire as the lead terminal A6, and the end of the twist-shaped metal wire 2 as the lead terminal B7 ;

[0044] ③ Wrap the twist-shaped metal wire 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com