Solar reflective condensation panel

A technology for reflecting concentrators and the sun, applied in the field of solar concentrators, can solve the problems of large thermal expansion and contraction, short service life, low reflective efficiency, etc., and achieve high fatigue resistance, long service life, good reflection rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

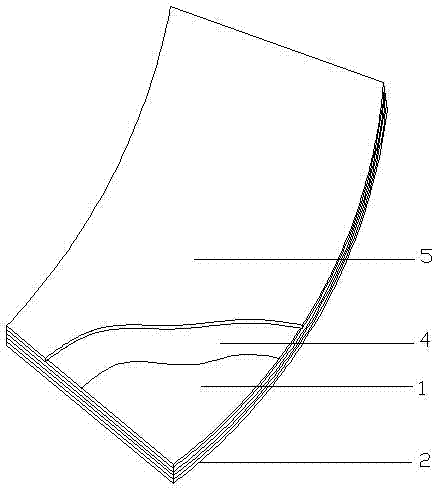

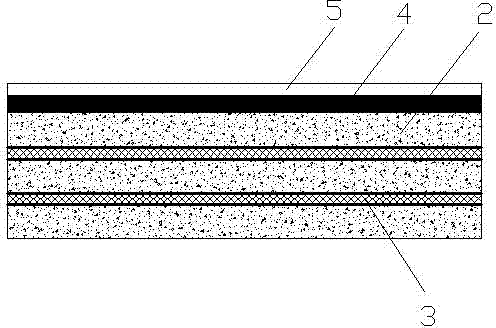

[0020] Example 1, such as figure 1 with figure 2 A kind of solar reflection concentrating panel shown, comprises composite panel 1, and described composite panel is a parabolic panel, has good light-gathering effect, and composite panel comprises 3 layers of composite layers 2, and is set between adjacent two layers of composite layers. Metal mesh 3 is arranged, and the sunken surface of composite plate is provided with light-reflecting layer 4, and the outer surface of light-reflecting layer is provided with protective film 5, and the light-reflecting layer in the present embodiment is aluminum thin film, and thickness is 30nm, and protective film is TiO 2 film, the thickness of the protective film is 20nm, the composite layer 2 is made of the following components in mass percentage: resin 20%, glass fiber 50%, carbon fiber 30%, the thickness of the composite layer is 2.0mm, and the resin adopts acid value in 70~75mgKOH / g, carboxyl-terminated polyester resin with a softenin...

Embodiment 2

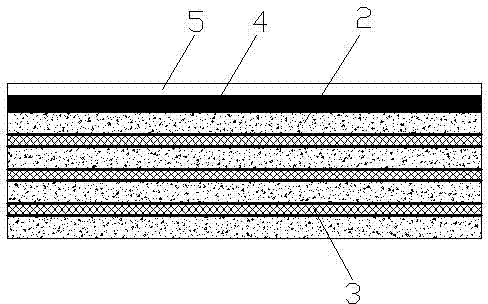

[0021] Embodiment 2: as figure 1 with image 3 A solar reflective concentrating panel shown includes a composite panel 1, the composite panel is a parabolic panel, the composite panel includes 4 composite layers 2, and a metal mesh 3 is arranged between adjacent two composite layers, and the composite panel The sunken surface of the is provided with reflective layer 4, and the thickness of composite layer is 1.5mm, and the outer surface of reflective layer is provided with protective film 5, and the reflective layer in the present embodiment is aluminum thin film, and thickness is 40nm, and protective film is TiO 2 Thin film, the thickness of the protective film is 10nm, the composite layer 2 is made of the following components in mass percentage: resin 25%, glass fiber 55%, carbon fiber 20%, resin with an acid value of 70-75mgKOH / g, softening point It is a carboxyl-terminated polyester resin at 85~95°C. Both carbon fiber and glass fiber in this kind of composite board have ...

Embodiment 3

[0022] Example 3, such as figure 1 with Figure 4 A solar reflective concentrating panel shown includes a composite panel 1, the composite panel is a parabolic panel, the composite panel includes five composite layers 2, and a metal mesh 3 is arranged between adjacent two composite layers, and the composite panel The sunken surface of the is provided with reflective layer 4, and the thickness of composite layer is 1.2mm, and the outer surface of reflective layer is provided with protective film 5, and the reflective layer in the present embodiment is aluminum thin film, and thickness is 50nm, and protective film is TiO 2film, the thickness of the protective film is 5nm, and the composite layer 2 is made of the following components in mass percentage: 30% resin, 60% glass fiber, and 10% carbon fiber. Since there are 4 layers of metal mesh in the composite plate, the metal mesh To set the shape and increase the connection strength, so the content of carbon fiber can be slightly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com