Irradiation device and synthesis method for preparing hydrogel sheet through cobalt-60 radioactive source

A technology of irradiation device and synthesis method, applied in irradiation device, nuclear engineering and other directions, can solve the problem of uneven thickness of sheets, and achieve the effects of uniform thickness, high production efficiency, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

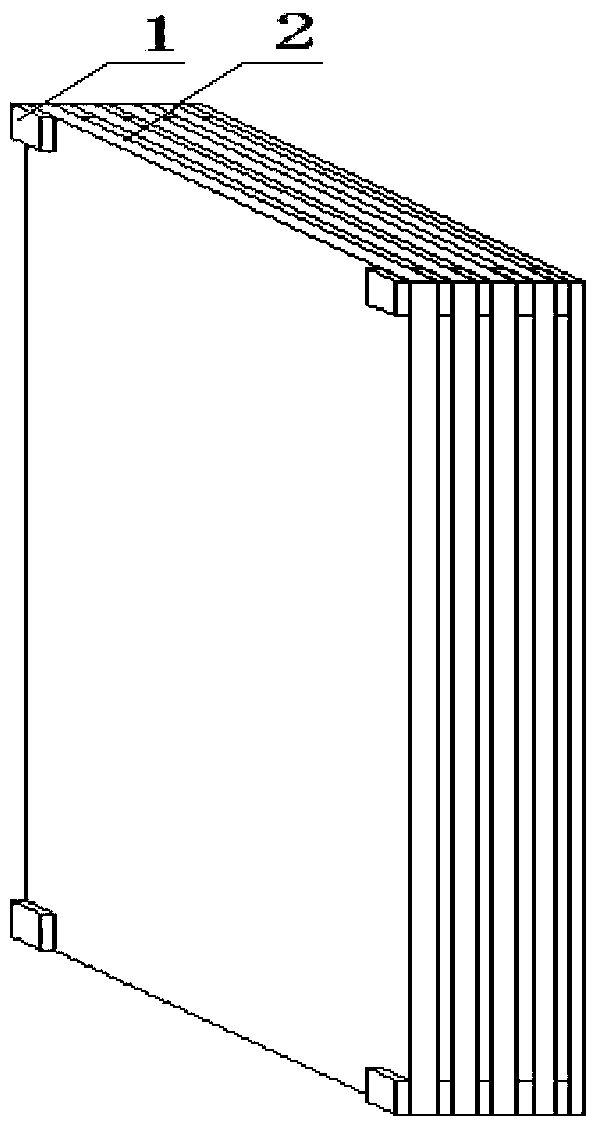

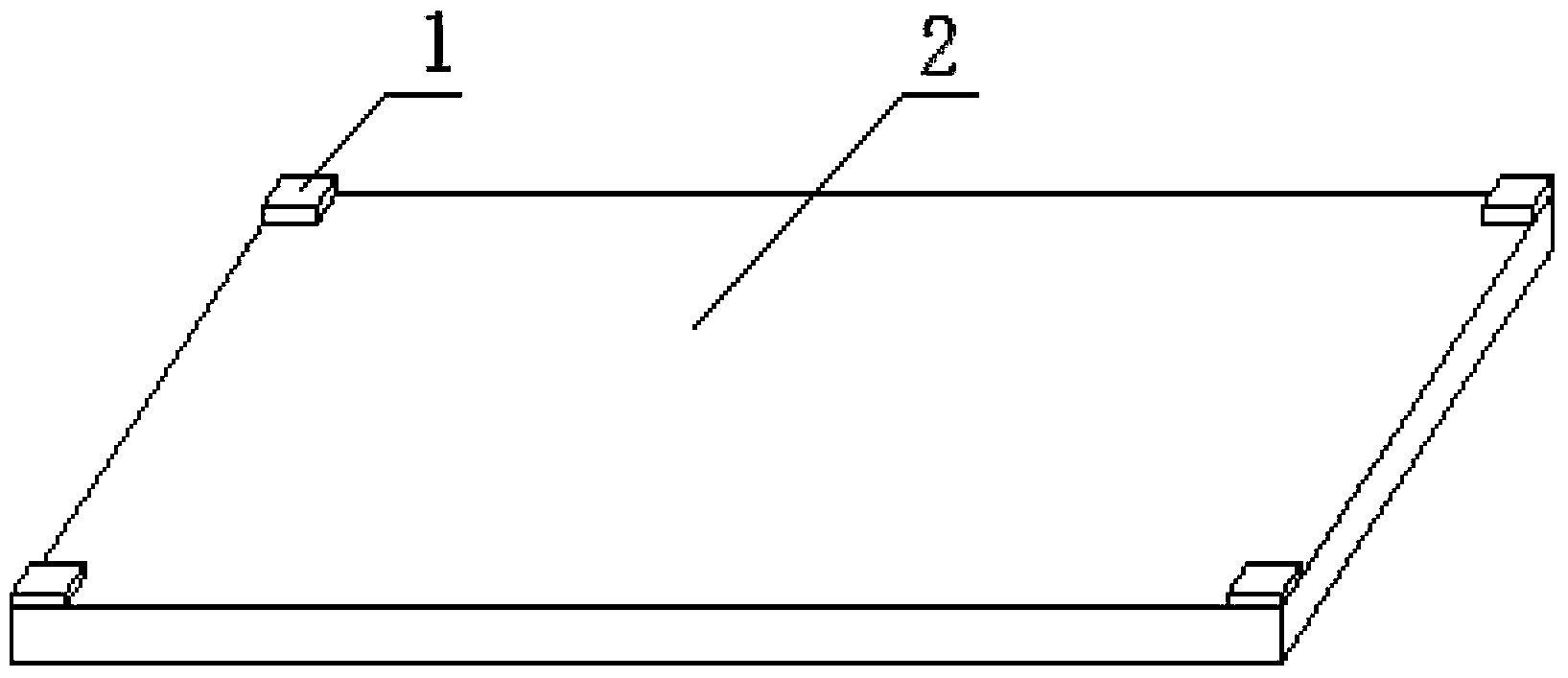

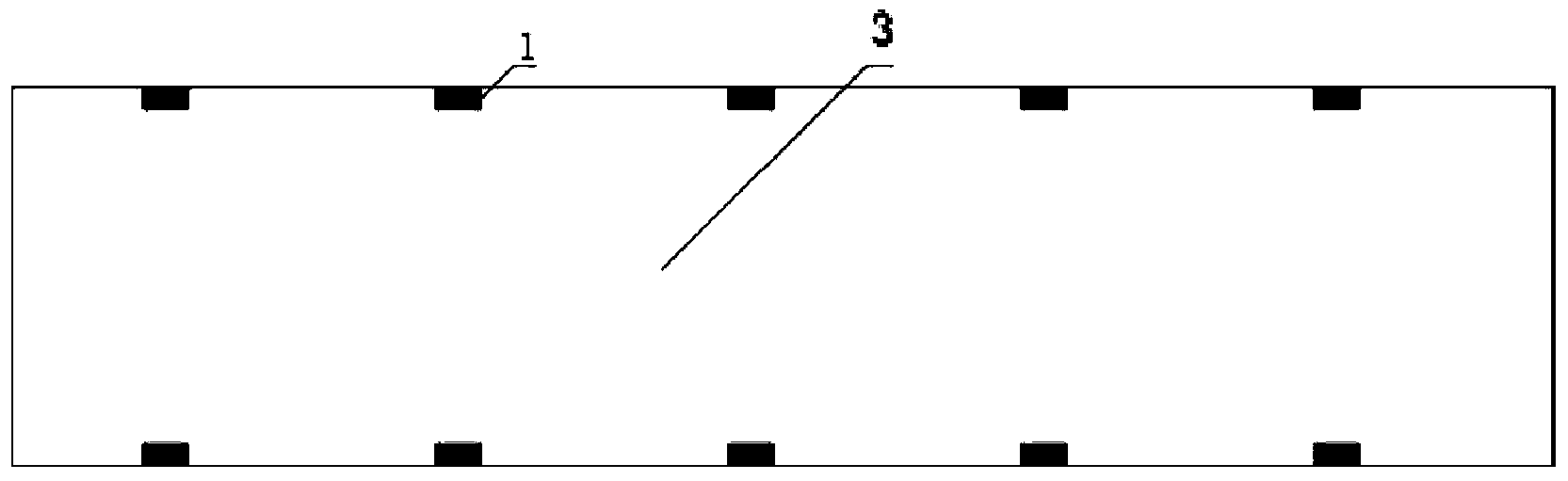

Embodiment 1

[0036]Put agar, polyvinyl alcohol, polyethylene glycol and water in a mass ratio of 2:6:4:88 into a reaction device that can be heated and stirred, heat up and stir to prepare a hydrogel raw material solution, and wait for vacuum defoaming use. Prepare a hydrogel-formed scaffold with a gap of 3mm (that is, a gasket thickness of 3mm), made of a PET plate with a thickness of 3mm, and put it into the container with the hydrogel sheet vertical to the horizontal plane. After filling the hydrogel raw material solution into the container, the container is sealed. A 30kGy irradiation dose is irradiated to the container containing the gel raw material solution and the gel forming bracket, so that the hydrogel raw material solution is cross-linked to form a gel. The hydrogel-formed scaffold is decomposed to obtain a hydrogel sheet. The thickness deviation range of the obtained hydrogel sheet (difference between the thickest part and the thinnest part) is 0-0.25mm, and the edges of the...

Embodiment 2

[0038] Put polyglutamic acid and water in a mass ratio of 10:90 into a reaction device that can be heated and stirred, heat up and stir and mix to prepare a hydrogel raw material liquid, and vacuum defoam it for use. Prepare a hydrogel roll forming bracket with a gap of 50mm, made of a PET sheet with a thickness of 1mm, and put it into the container in the direction of the hydrogel sheet perpendicular to the horizontal plane. After filling the hydrogel raw material solution into the container, the container is sealed. The container containing the gel raw material solution and the gel forming bracket is irradiated with an irradiation dose of 80kGy, so that the hydrogel raw material solution is cross-linked to form a gel. The hydrogel-formed scaffold is decomposed to obtain a hydrogel sheet. The thickness deviation range of the obtained hydrogel sheet (the difference between the thickest part and the thinnest part) is 0-0.28mm, and the edges of the gel are neat; in the case of ...

Embodiment 3

[0040] Put PVA and water in a mass ratio of 5:95 into a reaction device that can be heated and stirred, heat up and stir to prepare a hydrogel raw material solution, and vacuum defoam it for use. Prepare a hydrogel sheet molding bracket with a gap of 10mm, made of acrylic plate with a thickness of 3mm, and put it into the container in the direction of the vertical and horizontal plane of the hydrogel sheet. After filling the hydrogel raw material solution into the container, the container is sealed. The container containing the gel raw material solution and the gel forming bracket is irradiated with an irradiation dose of 100 kGy, so that the hydrogel raw material solution is cross-linked to form a gel. The hydrogel-formed scaffold is decomposed to obtain a hydrogel sheet. The thickness deviation range of the obtained hydrogel sheet (difference between the thickest part and the thinnest part) is 0-0.5mm, and the edges of the gel are neat; in the case of the same raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com