Recycling process for active material of waste cathode piece of lithium ion battery

A technology for lithium ion batteries and active materials, which is applied in the field of regeneration technology of active materials of waste cathode sheets of lithium ion batteries, can solve the problems of complex process flow, large secondary pollution and high recycling cost, and achieves simple process and low production cost. , the effect of avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

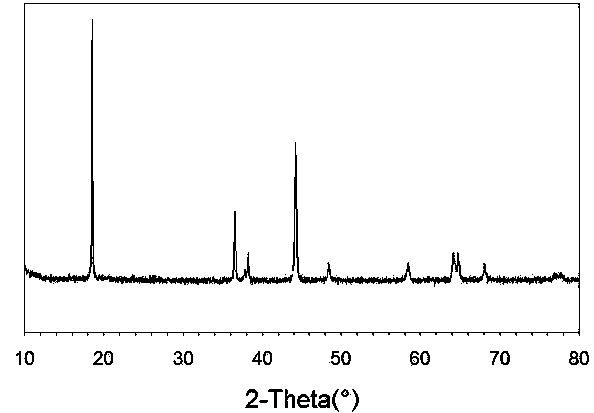

[0014] (1) For collected ternary materials (LiCo x Ni y mn z o 2 , x+y+z=1) Sorting the waste positive electrodes of the secondary battery, cleaning the waste positive electrodes with dirty surface with ethanol, acetone or N-methylpyrrolidone to clean the surface and proceed to step (2), Clean positive electrode waste can directly enter step (2);

[0015] (2) Rinse 50g of clean positive electrode waste with 200ml of a stripping agent containing a sulfuric acid solution with a mass concentration of 35% repeatedly, so that the drug film surface on the positive electrode waste is in effective contact with the stripping agent, and the ambient temperature is kept at 30°C. 1h;

[0016] (3) Take out the positive electrode waste sheet in step (2), shake it gently, (ultrasound, stirring can be used) the drug film surface containing the active substance will naturally fall off the aluminum foil, and remove the aluminum foil;

[0017] (4) Wash and filter the shedding solid with 50ml...

Embodiment 2

[0024] (1) For collected LiMn 2 o 4 Sorting the waste positive electrodes of the secondary battery, cleaning the waste positive electrodes with dirty surface with ethanol, acetone or N-methylpyrrolidone, making the surface clean and then proceeding to step (2), the clean positive electrode waste can directly enter the step (2);

[0025] (2) Soak 50g of clean positive electrode waste in 1L of stripping agent containing sulfuric acid solution with a mass concentration of 10%, so that the drug film surface on the positive electrode waste is in effective contact with the stripping agent, and the ambient temperature is maintained at -10°C 36h;

[0026] (3) Take out the positive electrode waste sheet in step (2), shake it gently, (ultrasound, stirring can be used) the drug film surface containing the active substance will naturally fall off from the aluminum foil, and remove the aluminum foil;

[0027] (4) Wash the filtered solid with 50ml of absolute ethanol for 3 times, and the w...

Embodiment 3

[0033] (1) For collected LiMn 2 o 4 Sorting the positive electrode waste of the secondary battery, cleaning the positive electrode waste with dirty surface with ethanol, acetone or N-methylpyrrolidone, making the surface clean and then proceeding to step (2), the clean positive electrode waste can directly enter the step (2);

[0034] (2) Soak 50g of clean positive electrode waste in 1L of stripping agent containing 90% sulfuric acid solution, so that the drug film surface on the positive electrode waste is in effective contact with the stripping agent, and the ambient temperature is maintained at 120°C at 0.1 h;

[0035] (3) Take out the positive electrode waste sheet in step (2), shake it gently, (ultrasound, stirring can be used) the drug film surface containing the active substance will naturally fall off the aluminum foil, and remove the aluminum foil;

[0036] (4) Wash the filtered solid with 50ml of absolute ethanol for 3 times, and the washed absolute ethanol can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com