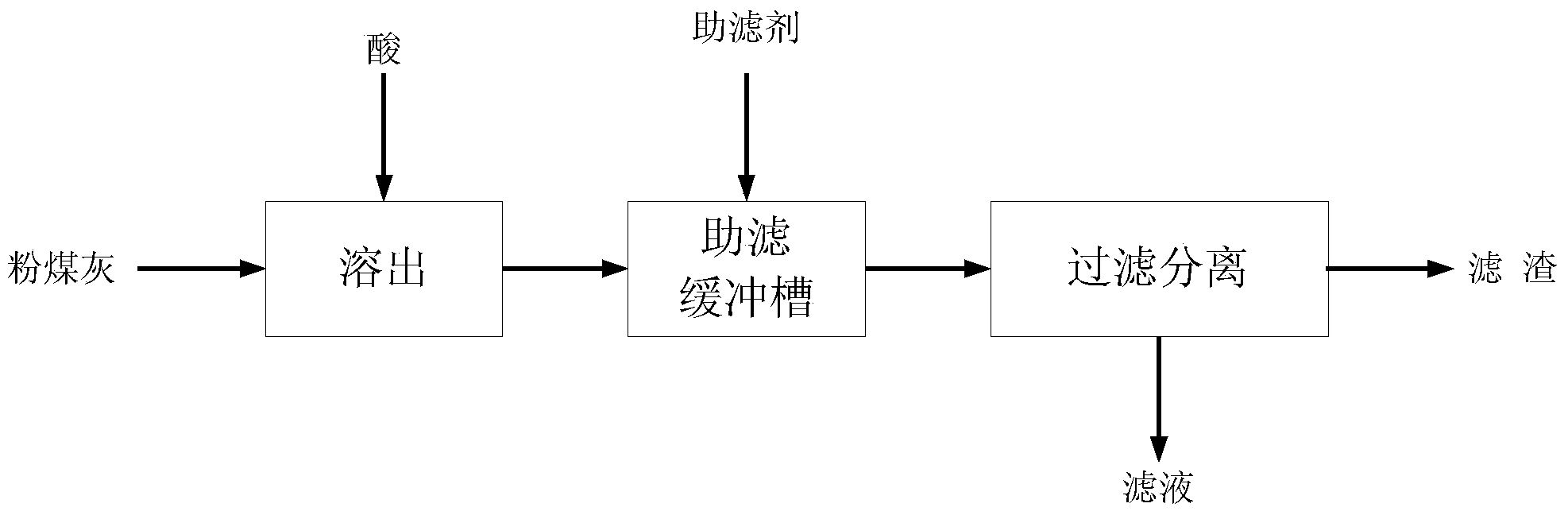

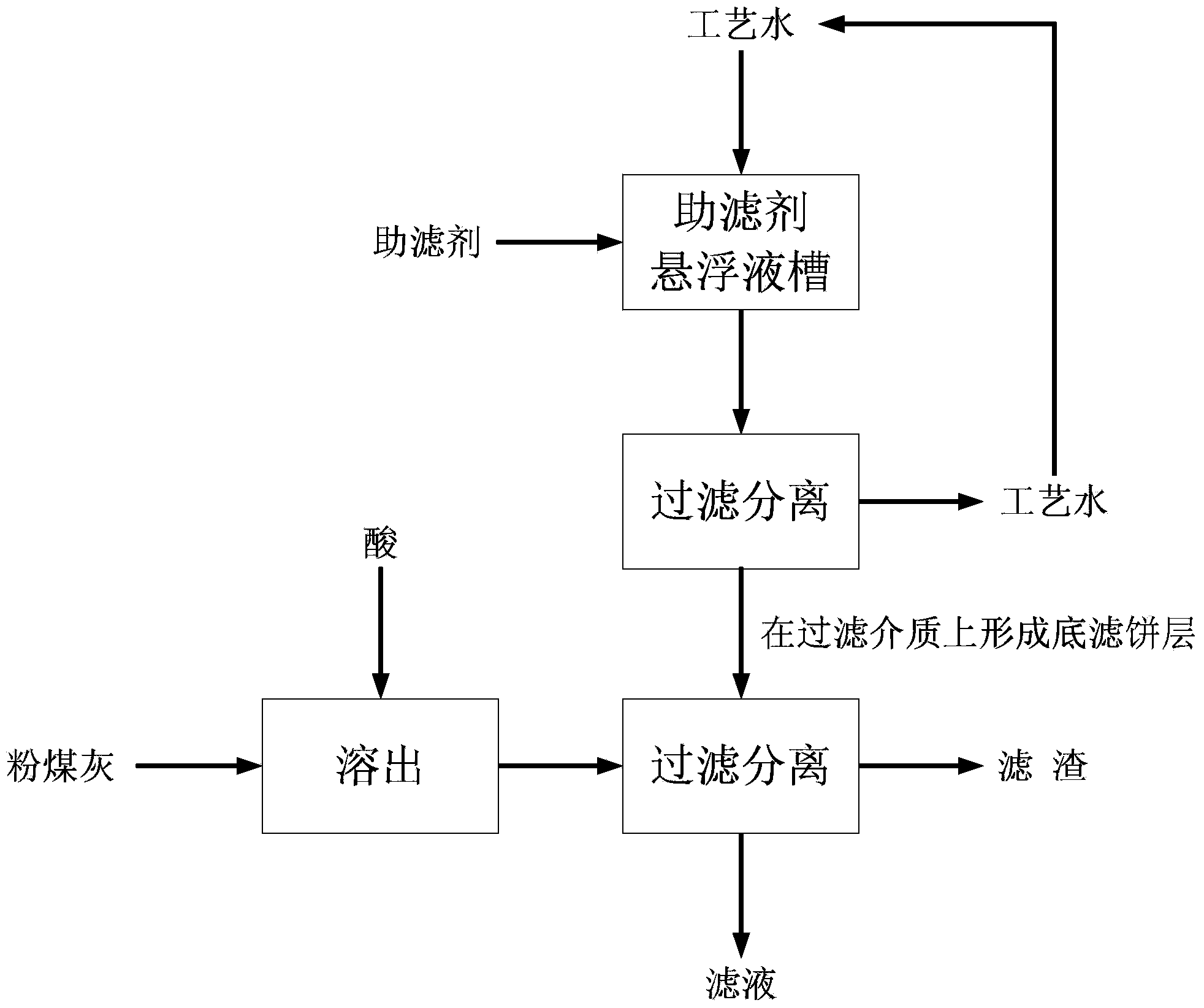

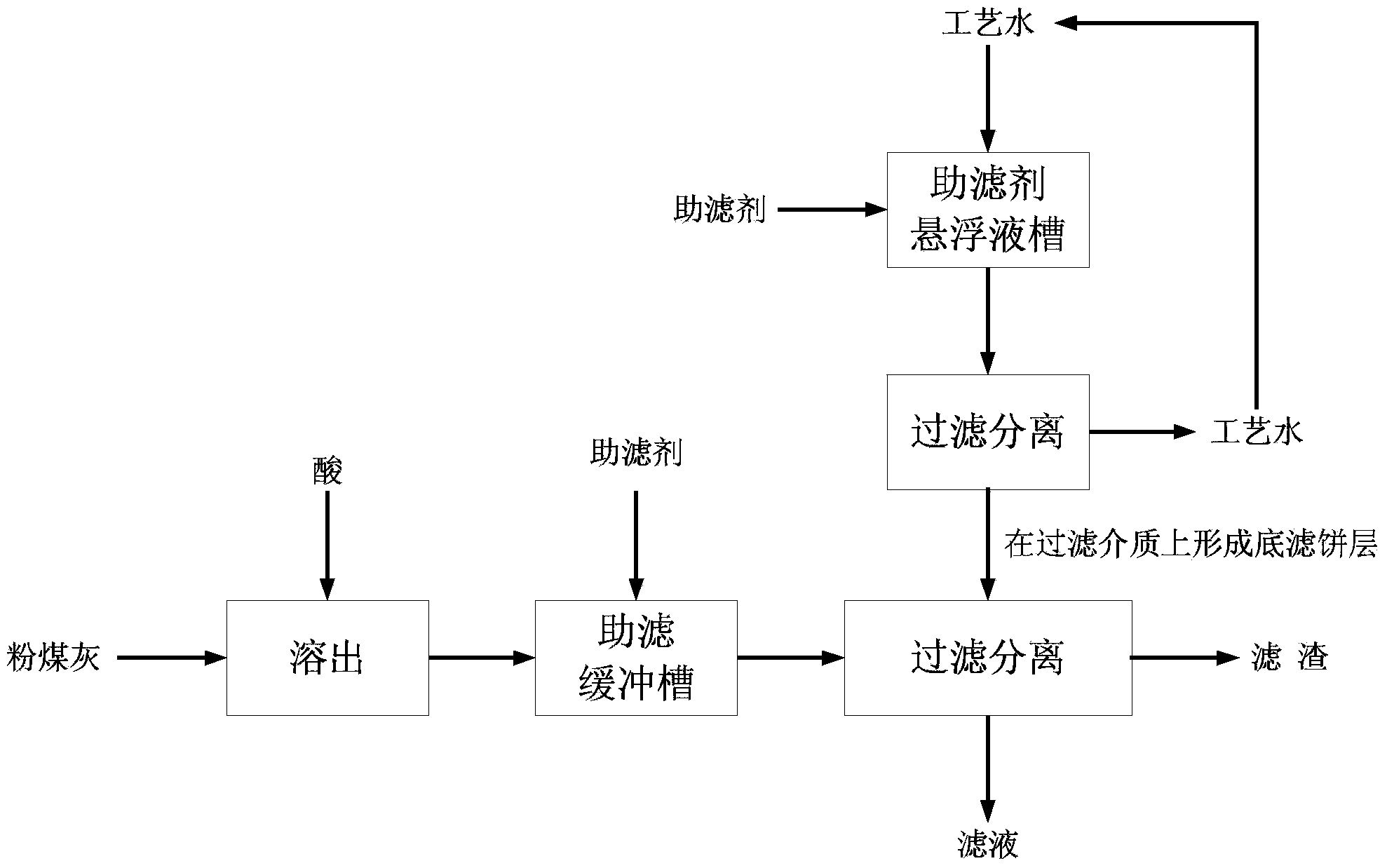

Method for improving filtering property of acid coal ash slurry

A filter performance, fly ash technology, applied in the field of fly ash resource utilization, to achieve the effect of stable chemical composition, convenient use, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Taking fly ash 10% hydrochloric acid chemical iron removal slurry as an example, polyacrylamide (improved, cationic, molecular weight about 500,000 to 1,000,000) was used as flocculant, and 100mL1g L was prepared in advance -1For polyacrylamide solution, pipette 2.0mL and mix it with 300mL fly ash slurry at a speed of 300r·min -1 Stir at low temperature for 10s, and filter under the conditions that the filter medium is polypropylene (polypropylene, PP) acid-resistant filter cloth, the size is Φ100mm, the vacuum degree is 0.07MPa, and the temperature is 75-80°C. The effective filtration time is 19min46s without additives Shortened to 1min3s, the water content of the filter cake decreased from 61.3% without additives to 44.3%, and the chemical composition of the filtrate remained unchanged.

Embodiment 2

[0036] Taking the slurry chemically activated by 15% hydrochloric acid of fly ash as an example, polyacrylamide (improved, cationic, with a molecular weight of about 500,000 to 1,000,000) was used as a flocculant, and 100 mLg L was prepared in advance -1 For polyacrylamide solution, pipette 2.0mL and mix it with 300mL fly ash slurry at a speed of 300r·min -1 Stir at low temperature for 10s, and filter under the condition that the filter medium is polypropylene (polypropylene, PP) acid-resistant filter cloth, the size is Φ100mm, the vacuum degree is 0.07MPa, and the temperature is 55-60°C. The effective filtration time is 17min8s without adding flocculant Shortened to 1min18s, the water content of the filter cake was reduced from 60.2% without flocculant to 43.8%, and the chemical composition of the filtrate was stable.

[0037] Among them, the improvement of polyacrylamide is mainly through temperature or pH adjustment, dispersing machine, adding CO 2 Or polyethylene glycol a...

Embodiment 3

[0039] Taking fly ash chemically activated slurry with 7% sulfuric acid as an example, polyethylene glycol 4000 was used as surfactant, and 100mL2g L was prepared in advance -1 Polyethylene glycol solution, pipette 5.0mL, mix with 300mL fly ash slurry, at a speed of 300r min -1 Stir at low temperature for 10s, and filter under the conditions that the filter medium is polypropylene (polypropylene, PP) acid-resistant filter cloth, the size is Φ100mm, the vacuum degree is 0.07MPa, and the temperature is 55-60°C. The effective filtration time is 13min28s without additives Shortened to 56s, the water content of the filter cake was reduced from 55.6% without additives to 39.8%, and the chemical composition of the filtrate was stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com