Gas static purification method based on rotary polar lines

A gas and electrostatic technology, applied in the field of air purification, can solve the problems of poor trapping effect, single action, poor trapping effect of fine particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

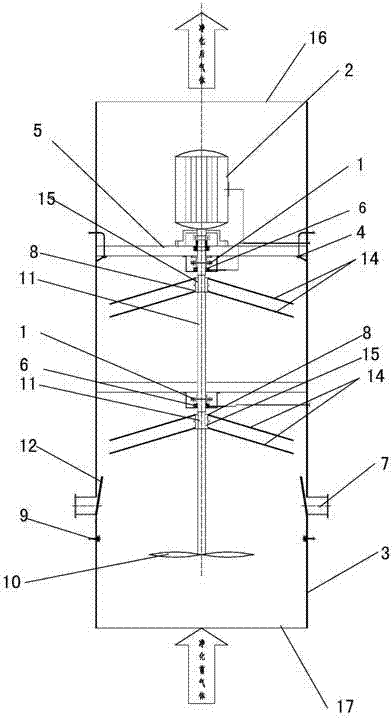

[0045] Below in conjunction with accompanying drawing, the device used in the method of the present invention is further explained:

[0046] Below in conjunction with accompanying drawing, device of the present invention is further explained:

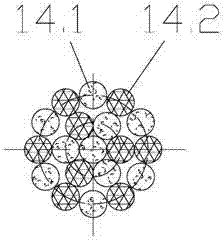

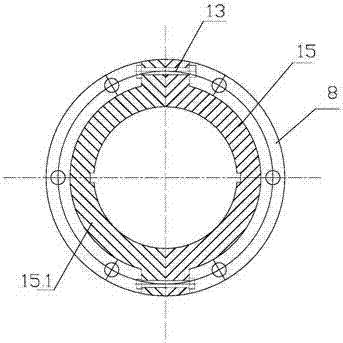

[0047] The bottom of the cylinder 3 is provided with an air inlet 16, and the top is provided with an air outlet 17. A motor 2 is provided at the central axis of the cylinder 3 on the upper section of the cylinder 3, and the motor 2 is fixed on the inner wall of the cylinder 3 via a support beam 5. The rotating shaft of the motor 2 (one motor is used in this embodiment) is connected in series with two layers (could be multi-layer, two layers in this embodiment) of electrostatic components, and the electrostatic components include an insulating coupling 1 and an insulating wire The live shaft 11 connected by the coupling (which can be guided and supported by the bearing system), through the insulating coupling 1, the rotating shaft of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com