A kind of heavy metal sewage treatment agent and preparation method thereof

A sewage treatment agent, heavy metal technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, treatment effect needs to be improved, high treatment cost, and achieve high performance Stable, good treatment effect, rapid precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

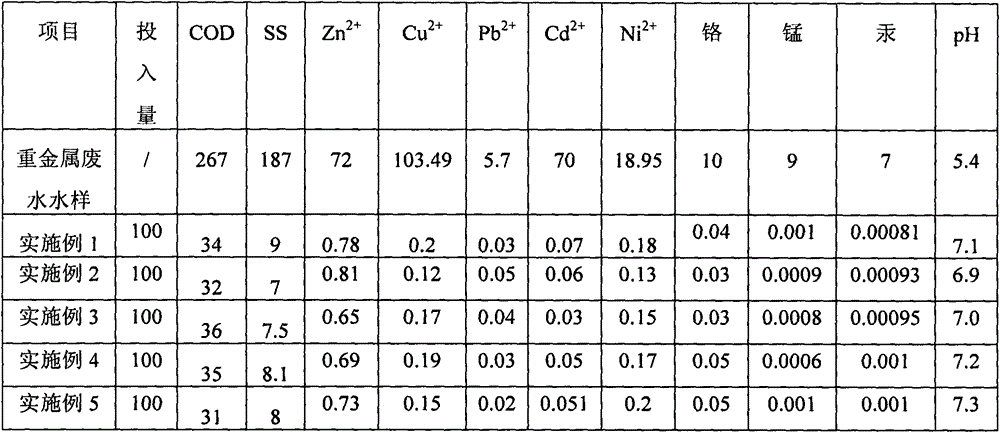

Examples

Embodiment 1

[0040] A heavy metal sewage treatment agent comprising the following raw materials in parts by weight: 2 parts of aminotrimethylene phosphonic acid, 5 parts of ethylene glycol diethyl ether diamine tetraacetic acid, 10 parts of sodium polyacrylate, diethylenetriamine 15 parts of pentasodium pentaacetate, 10 parts of polyaspartic acid, 30 parts of starch xanthate, graphene nanolayer (GNS) / MnO 2 3 parts of composite, 20 parts of cross-linked rectorite, 10 parts of polyaluminum chloride, 10 parts of chitosan-graphene composite material, and the balance is deionized water.

[0041] A preparation method of a heavy metal sewage treatment agent, the preparation steps are as follows:

[0042] A, take raw material according to weight portion, open container, add deionized water;

[0043] B. Add graphene nanolayer (GNS) / MnO 2 Composite, chitosan-graphene composite material, ultrasonic vibration for 10 minutes; preferably, the ultrasonic frequency is 1000W;

[0044] C. Add aminotrimet...

Embodiment 2

[0047] The heavy metal sewage treatment agent described in this embodiment includes the following raw materials in parts by weight: 0.5 part of aminotrimethylene phosphonic acid, 3 parts of ethylene glycol diethyl ether diamine tetraacetic acid, 20 parts of sodium polyacrylate, pentasodium diethylenetriaminepentaacetic acid 5 parts, polyaspartic acid 14 parts, starch xanthate 25 parts, graphene nanolayer (GNS) / MnO 2 5 parts of composite, 15 parts of cross-linked rectorite, 30 parts of polyaluminum chloride, 6 parts of chitosan-graphene composite material, and the balance is deionized water.

[0048] A preparation method of a heavy metal sewage treatment agent, the preparation steps are as follows:

[0049] A, take raw material according to weight portion, open container, add deionized water;

[0050] B. Add graphene nanolayer (GNS) / MnO 2 Composite, chitosan-graphene composite material, ultrasonic vibration for 15 minutes; preferably, the ultrasonic frequency is 1200W;

[00...

Embodiment 3

[0054] The heavy metal sewage treatment agent described in this embodiment includes the following raw materials in parts by weight: 1 part of aminotrimethylene phosphonic acid, 4 parts of ethylene glycol diethyl ether diamine tetraacetic acid, 12 parts of sodium polyacrylate, pentasodium diethylenetriaminepentaacetic acid 13 parts, 10 parts of sodium persulfate, 20 parts of polyaspartic acid, 20 parts of starch xanthate, graphene nanolayer (GNS) / MnO 2 6 parts of composite, 16 parts of cross-linked rectorite, 15 parts of polyaluminum chloride, 9 parts of chitosan-graphene composite material, and the balance is deionized water.

[0055] A preparation method of a heavy metal sewage treatment agent, the preparation steps are as follows:

[0056] A, take raw material according to weight portion, open container, add deionized water;

[0057] B. Add graphene nanolayer (GNS) / MnO 2 Composite, chitosan-graphene composite material, ultrasonic vibration for 18 minutes; preferably, the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com