Sewage treatment agent

A sewage treatment agent, sisal fiber technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor treatment effect, secondary pollution, high treatment cost, etc. , to achieve the effect of good treatment effect, stable performance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

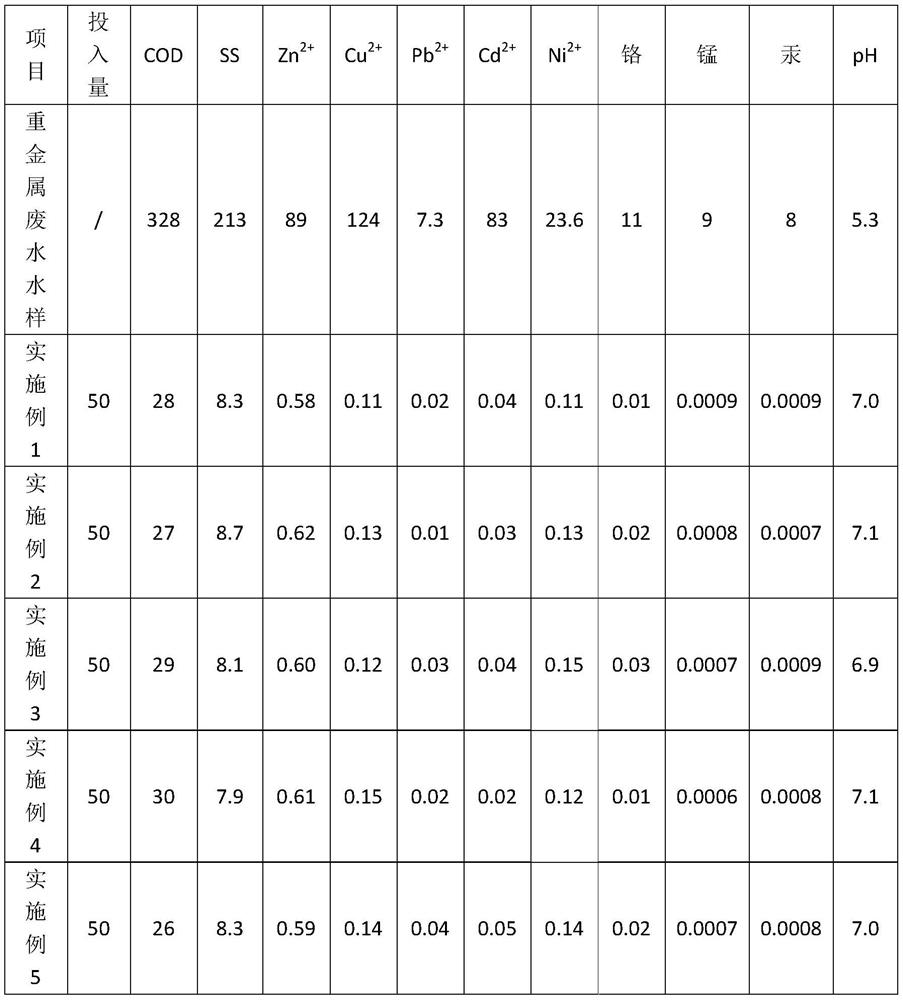

Examples

Embodiment 1

[0035] A sewage treatment agent, comprising the following raw materials in parts by weight: 5 parts of lactic acid, 20 parts of modified sisal fiber porous microspheres, 5 parts of polyglycine, 5 parts of starch xanthate and 1 part of aminotrimethylene phosphonic acid; Modified sisal fiber porous microspheres are obtained by modifying sisal fiber with citric acid, activating 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, and crosslinking chitosan Citric acid modified sisal fiber cross-linked chitosan porous microspheres.

[0036] A preparation method of sewage treatment agent, comprising:

[0037] Preparation of modified sisal fiber porous microspheres:

[0038] Dissolve sisal fiber in citric acid, then add sodium hypophosphite, the molar ratio of sisal fiber, citric acid and sodium hypophosphite is 1:4:0.01, carry out hydrothermal reaction in autoclave, hydrothermal reaction The temperature is 100°C, and the reaction time is 4 hours. After the reaction, centri...

Embodiment 2

[0044]A sewage treatment agent, comprising the following raw materials in parts by weight: 6 parts of hydroxybutyric acid, 22 parts of modified sisal fiber porous microspheres, 6 parts of polyasparagine, 6 parts of starch xanthate and amino trimethylene phosphine 2 parts of acid; modified sisal fiber porous microspheres are citric acid modified sisal fiber crosslinked chitosan obtained by citric acid modification, N-hydroxysuccinimide activation and chitosan crosslinking of sisal fiber porous microspheres.

[0045] A preparation method of sewage treatment agent, comprising:

[0046] Preparation of modified sisal fiber porous microspheres:

[0047] Dissolve sisal fiber in citric acid, then add sodium hypophosphite, the molar ratio of sisal fiber, citric acid and sodium hypophosphite is 1:5:0.05, carry out hydrothermal reaction in autoclave, hydrothermal reaction The temperature is 110°C, and the reaction time is 4.5 hours. After the reaction, centrifuge, remove the lower laye...

Embodiment 3

[0053] A sewage treatment agent, comprising the following raw materials in parts by weight: 7.5 parts of salicylic acid, 25 parts of modified sisal fiber porous microspheres, 7.5 parts of polyglutamic acid, 7.5 parts of starch xanthate and aminotrimethylene phosphine 3 parts of acid; modified sisal fiber porous microspheres are sisal fiber modified by citric acid, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride activation, chitosan Cross-linking obtained citric acid modified sisal fiber cross-linked chitosan porous microspheres.

[0054] A preparation method of sewage treatment agent, comprising:

[0055] Preparation of modified sisal fiber porous microspheres:

[0056] Dissolve sisal fiber in citric acid, then add sodium hypophosphite, the molar ratio of sisal fiber, citric acid and sodium hypophosphite is 1:6:0.1, carry out hydrothermal reaction in autoclave, hydrothermal reaction The temperature is 120°C, and the reaction time is 5 hours. After the reaction, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com