A kind of extinction type black polyimide resin and preparation method thereof

A polyimide resin, black polyimide technology, applied in the field of polymer materials, can solve problems such as complex methods, and achieve the effects of simple operation, good bonding strength and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

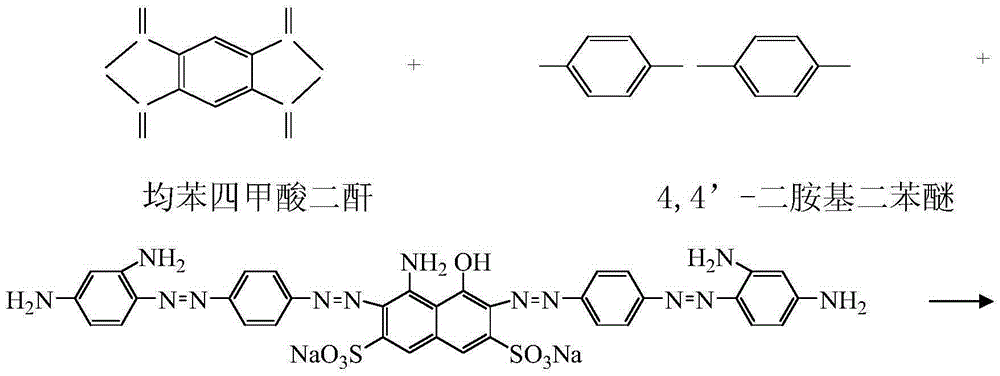

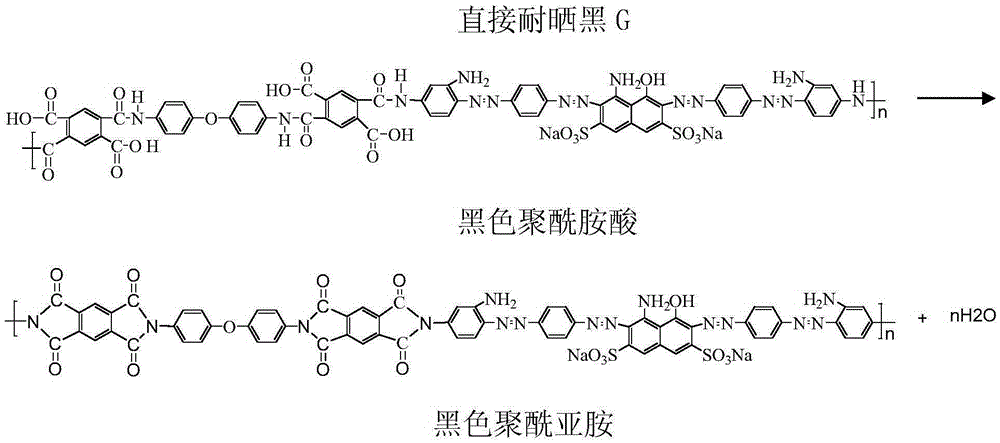

Method used

Image

Examples

Embodiment 1

[0030] 1. Weigh 22.52g of direct suntan G and dissolve it in 159.39g of dimethylformamide, stir for 2 hours at a speed of 150min / r, and stand still for 4 hours. The upper layer solution is high-purity direct suntan G solution, high purity The content of the direct sun black G in the direct sun black G solution is 7.58%, and it is for use;

[0031] 2. Raise the temperature of the water bath to 36°C; add 295.09g of dimethylformamide into the flask, adjust the stirrer to 90min / r, add 36.24g of 4,4'-diaminodiphenyl ether into the flask, and stir until completely dissolved; slowly add 132.42g of the high-purity direct suntan G solution prepared in step 1 and 42.42g of pyromellitic dianhydride at the same time, the addition time is about 60min, and the reaction temperature of the materials is controlled at 40°C; stir evenly for 2h , to obtain a black polyamic acid solution;

[0032] 3. Laboratory coating, thermal imidization to form black polyimide film.

Embodiment 2

[0034] 1. Weigh 22.52g of direct diazonium black BH and dissolve it in 159.39g of dimethylacetamide, stir for 2 hours at a speed of 200min / r, and stand still for 4 hours. The upper solution is high-purity direct diazonium black BH solution, high-purity The content of direct diazo black BH in the direct diazo black BH solution is 7.58%, stand-by;

[0035] 2. Raise the temperature of the water bath to 36°C; add 295.09g of dimethylacetamide into the flask, adjust the stirrer to 90min / r, add 36.24g of aromatic diamide into the flask, and stir until completely dissolved; slowly and simultaneously Add 132.42g of the high-purity direct diazonium black BH solution prepared in step 1 and 42.42g of benzophenone dianhydride, the addition time is about 60min, and the reaction temperature of the materials is controlled at 40°C; uniformly stirred for 2h to obtain black polyamic acid solution.

[0036] 3. Conventional thermal imidization to form black polyimide film.

Embodiment 3

[0038] 1. Weigh 22.52g of C032 black base LS and dissolve it in 159.39g of dimethylformamide, stir for 2 hours at a speed of 180min / r, and stand still for 4 hours. The upper layer solution is high-purity C032 black base LS solution, high-purity C032 black base The content of C032 black base LS in LS solution is 7.58%;

[0039] 2. Raise the temperature of the water bath to 36°C; then add 295.09g of dimethylformamide into the flask, adjust the stirrer to 90min / r, add 36.24g of polyetherdiamine into the flask, and stir until completely dissolved; Slowly add 132.42g of the high-purity C032 black base LS solution prepared in step 1 and 42.42g of diphenyl ether dianhydride at the same time. The addition time is about 60 minutes, and the reaction temperature of the materials is controlled at 40°C; uniformly stirred for 2 hours to obtain black polyamide acid solution.

[0040] 3. Laboratory coating, thermal imidization to form black polyimide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com