Composite conductive film taking graphene as conductive agent and preparation method of composite conductive film

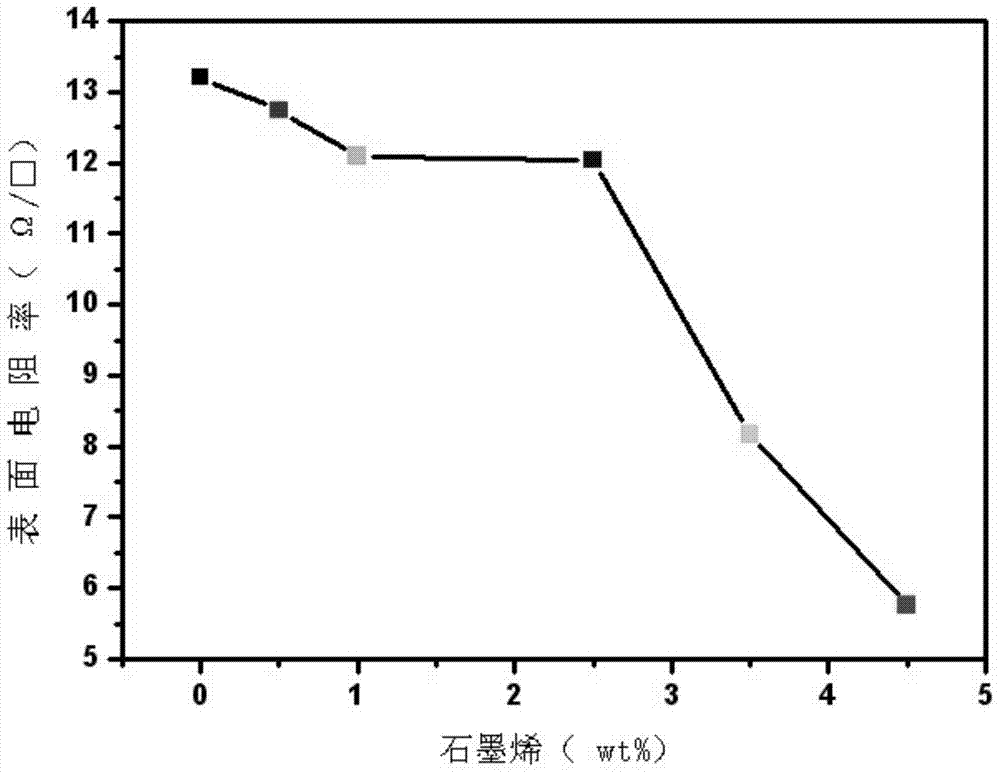

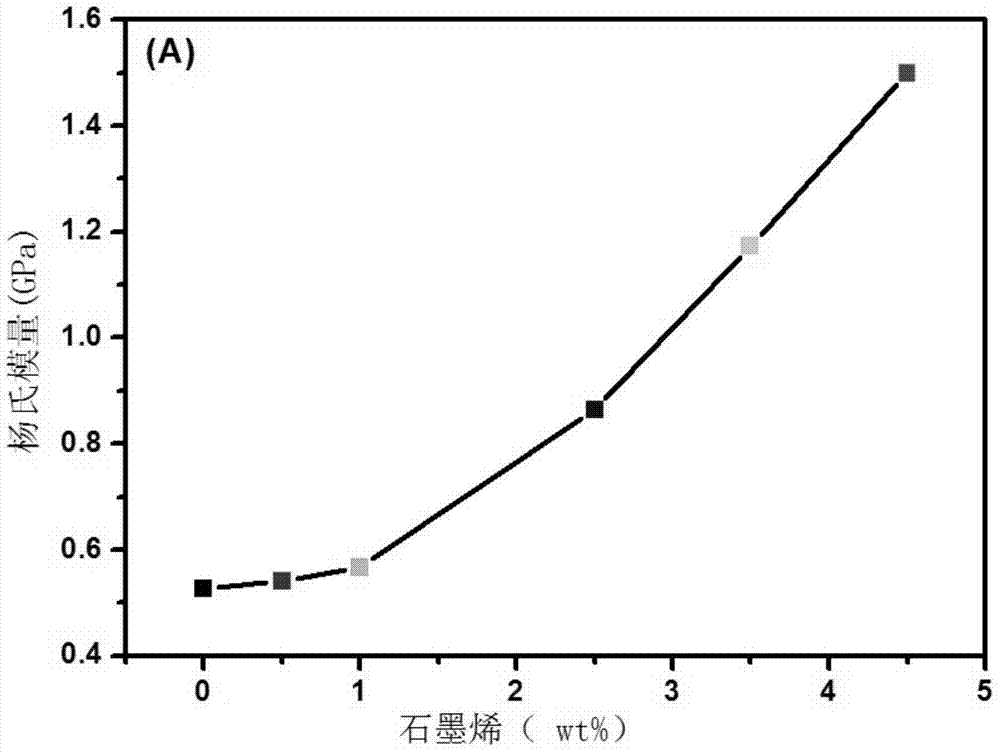

A composite conductive and composite film technology, applied in the field of thermoplastic resin polymer composite conductive film and its preparation, can solve the problems of easily destroying the graphene sheet structure, affecting the expected performance of the composite material, complicated preparation methods, etc., so as to improve the conductive performance. , the effect of light weight and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

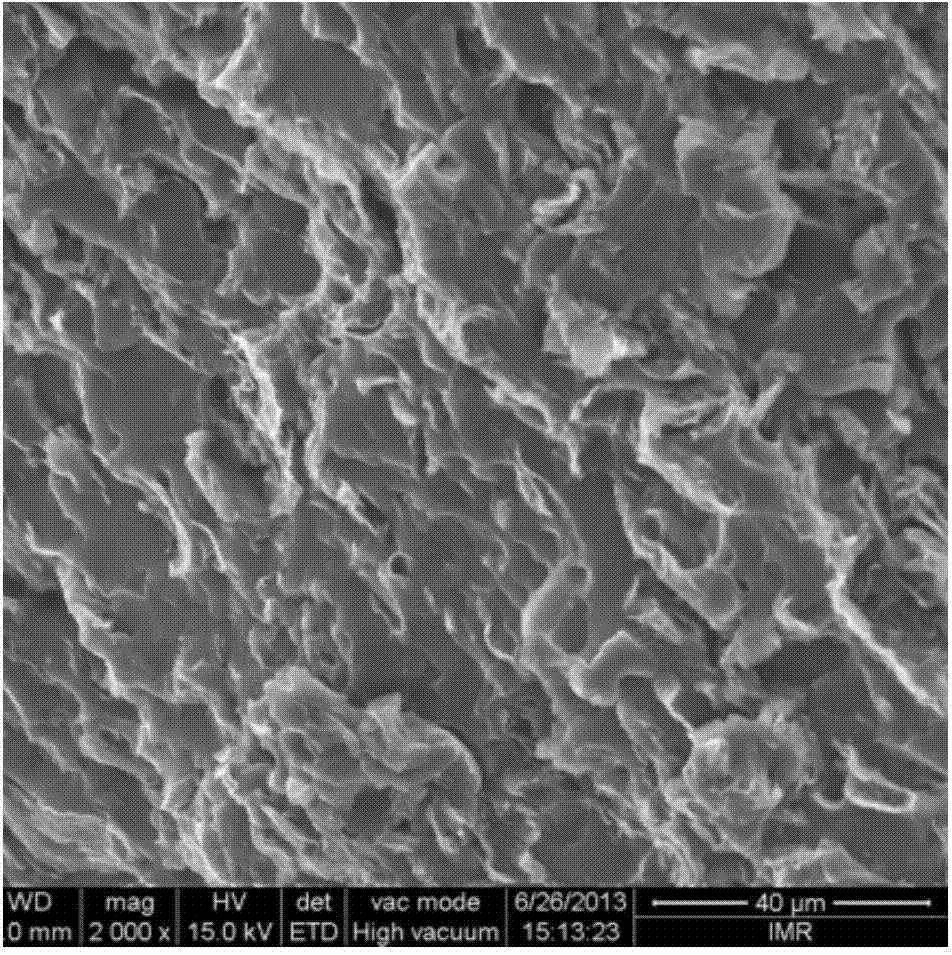

[0032] The graphene / thermoplastic resin polymer composite conductive film of the present invention is characterized in that the graphene is uniformly distributed and overlapped to form a conductive network through double-roll mixing to form an antistatic thermoplastic resin polymer composite material. First, liquid calcium and zinc are stabilized Add the plasticizer to the plasticizer and stir evenly, then add the thermoplastic resin polymer to it and stir evenly, then mature the evenly mixed material in the oven, then add the graphene and stir evenly, and finally mix it with a two-roll mixer. Graphene / thermoplastic resin polymer composite conductive film. The preparation method of graphene / thermoplastic resin polymer composite conductive film includes the following processes:

[0033] (1) After pre-mixing an appropriate amount of dioctyl phthalate (DOP) and liquid calcium zinc stabilizer, add an appropriate amount of thermoplastic resin into a high-speed mixer and stir for 5-20 ...

Embodiment 1

[0040] The graphene / polyvinyl chloride (PVC) composite conductive film was prepared, and the content of graphene in the composite conductive film material was 0.5wt%.

[0041] First, weigh 50g of polyvinyl chloride resin, 30g of dioctyl phthalate plasticizer and 2g of liquid calcium zinc stabilizer CH400 in the ratio of 100:60:4, and combine the dioctyl phthalate and liquid calcium zinc After the stabilizer is initially mixed, the weighed polyvinyl chloride resin is added to it, and the mixture is stirred in a high-speed mixer (speed of 5000 rpm) for 5-20 minutes to make it uniform, and then placed in an oven at 80°C for 1 hour. ; Then add 0.412g graphene powder to the cured PVC, stir for 5-20 minutes in a high-speed mixer (rotating speed of 5000rpm), and mix evenly to obtain a well-mixed graphene / PVC composite powder; finally the above composite powder It is added to the twin rolls of a small precision twin-roll mill. The temperature of the front and rear rolls are 170℃ and 168℃...

Embodiment 2

[0044] The graphene / PVC composite conductive film was prepared, and the content of graphene in the composite conductive film material was 2.5wt%.

[0045] The amount of graphene added was 2.1 g, and the remaining raw material ratio and preparation method were the same as in Example 1. A graphene / polyvinyl chloride composite conductive film with a graphene content of 2.5 wt% was prepared, and the thickness was 0.5 mm.

[0046] After testing, the volume resistance of the conductive film is 1.5×10 5 Ω, volume resistivity 7.3×10 7 Ω·cm; surface resistance 3.5×10 6 Ω, surface resistivity 1.1×10 8 Ω / □.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com