OCA (Optical Clear Adhesive) tape

A tape and optical technology, applied in the direction of adhesives, non-polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of poor heat resistance, difficult filling and bonding, fast curing and difficult bonding, etc.

Inactive Publication Date: 2014-03-19

常熟市富邦胶带有限责任公司

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the shortcomings of acrylate adhesives are also more obvious.

First of all, the heat resistance of acrylate adhesives is poor, and it cures quickly and is difficult to be used for large-area bonding. Without thickening, it is difficult to use for filling bonding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

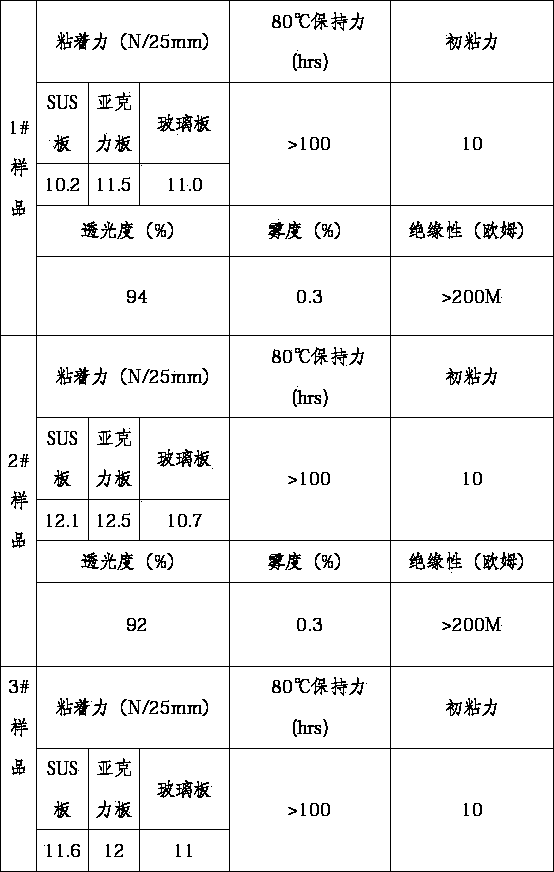

experiment example 1

[0014] Formula: cyanoacrylate: 100; polycyanoacrylate: 3; KH-550: 0.5; dibutyl ester: 3; copper acetate: 0.1.

experiment example 2

[0016] Formula: acrylate adhesive: 100; polycyanoacrylate: 3; KH-550: 0.5; tricresyl: 3; copper acetate: 0.1.

experiment example 3

[0018] Formula: acrylate adhesive: 100; acrylate: 3; KH-550: 0.5; dibutyl: 3; copper acetate: 0.1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an OCA (Optical Clear Adhesive) tape which sequentially comprises a light stripping PET (Poly Ethylene Terephthalate) release film layer, an OCA layer and a heavy stripping PET release film layer from top to bottom. The optical adhesive comprises the following components in parts by weight: 100 parts of acrylate adhesive, 3 parts of thickener, 0.5 parts of coupling agent, 3 parts of plasticizer and 0.1 parts of stabilizer. The OCA tape provided by the invention has better adhesive performance to various materials such as SUS plates, acrylic plates and glass plates. The OCA tape is better in transmission of light, and can be used for solving the technical problems that pollution is easily caused and the operation is inconvenient because bubbles are easily generated due to solidification and contraction of an existing liquid optical clear adhesive (LOCA) which has difficulty in thickness control in the market.

Description

technical field [0001] The invention mainly relates to an OCA optical adhesive tape, in particular to an OCA optical adhesive tape capable of better bonding properties to both inorganic glass and organic plastic sheets. Background technique [0002] The optical adhesive of OCA optical tape is a special adhesive used for bonding transparent optical components. It is characterized by colorless transparency, a light transmittance of more than 90%, good bonding strength, and can be cured at room temperature or medium temperature. With the characteristics of small curing shrinkage, it is mainly used for the bonding of ITO film, electronic paper, transparent devices, projection screen assembly, display assembly, lens assembly, resistive touch screen, capacitive touch screen, panel and other related electronic optical devices. Due to the different raw materials used, or the different preparation and measurement of the same raw materials, there are many kinds of optical adhesives. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J7/00C09J4/04C09J11/06C09J11/08C09J11/04

Inventor 沈阳

Owner 常熟市富邦胶带有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com