Low-temperature dry-distillation oil-extraction process of small-granule oil shale

A technology of oil mother shale and small particles, which is applied in the field of oil mother shale dry distillation, can solve the problems of abnormal production and operation, abandoned oil mother shale, small particle size of materials, etc., achieves significant social and economic benefits, and solves the effects of dust entrainment and environmental pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

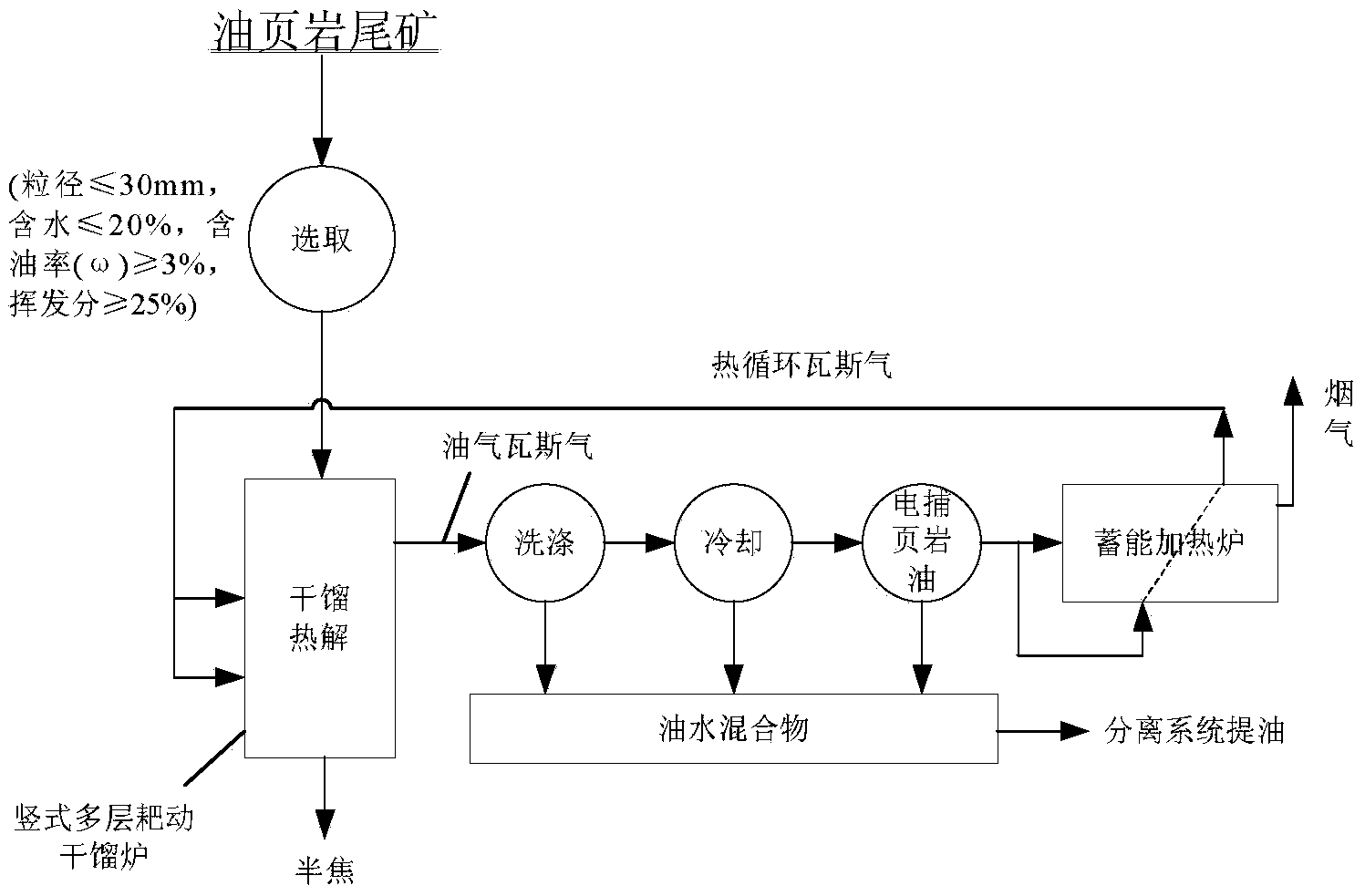

[0028] A low-temperature dry distillation pyrolysis oil extraction process of small particle kerogen shale, comprising the following steps:

[0029] 1. Select small-grain kerogen shale tailings by screening, select small-grain kerogen shale with a particle size of ≤30 mm, a water content of 19.8%, a volatile matter of 28.7%, and an oil content (ω) of 7.4% as materials, and send the materials to the top of the multi-stage furnace The material enters the drying section through the feeder and the feeding pipe. Under the thrust of the rake teeth in the furnace, the material is evenly pushed and turned on each furnace level, and moves down layer by layer, and is combined with the pyrolysis produced by the dry distillation section. And the hot oil, gas and gas that pass through the furnace layer of the preheating section and rise to the drying section are in countercurrent and mixed flow contact to complete the drying and dehydration process;

[0030] 2. After the dried oil shale ma...

Embodiment 2

[0036] A low-temperature dry distillation pyrolysis oil extraction process of small particle kerogen shale, comprising the following steps:

[0037] 1. Select small-grain kerogen shale tailings with particle size ≤30 mm, water content 17.2%, volatile matter 25.2%, oil content (ω) 3.0% as materials through screening, and feed the materials into the upper hopper of the multi-stage furnace, And enter the drying section through the feeder and the feeding pipe. Under the thrust of the rake teeth in the furnace, the material is evenly pushed and turned on each furnace level, and moves down layer by layer, and is combined with the pyrolysis produced by the dry distillation section. The hot oil, gas and gas in the preheating section rises from the furnace layer to the drying section in countercurrent and mixed flow contact to complete the drying and dehydration process;

[0038] 2. The dried kerogen shale material enters the preheating section through the drying section. Under the thr...

Embodiment 3

[0044] A low-temperature dry distillation pyrolysis oil extraction process of small particle kerogen shale, comprising the following steps:

[0045] 1. Select small grain kerogen shale tailings with particle size ≤30 mm, water content 9.8%, volatile matter 31.2%, and oil content (ω) 9.3% as materials through screening, and feed the materials into the upper hopper of the multi-stage furnace. And enter the drying section through the feeder and the feeding pipe. Under the thrust of the rake teeth in the furnace, the material is evenly pushed and turned on each furnace level, and moves down layer by layer, and is combined with the pyrolysis produced by the dry distillation section. The hot oil, gas and gas in the preheating section rises from the furnace layer to the drying section in countercurrent and mixed flow contact to complete drying and dehydration;

[0046] 2. The dried kerogen shale material enters the preheating section through the drying section. Under the thrust of ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com