A kind of Lactobacillus casei producing high optical purity L-lactic acid and fermentation method thereof

A technology of Lactobacillus casei and lactic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of low optical purity of L-lactic acid, achieve stable acid production capacity and purity, and low mutagenesis cost , The effect of reducing the cost of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

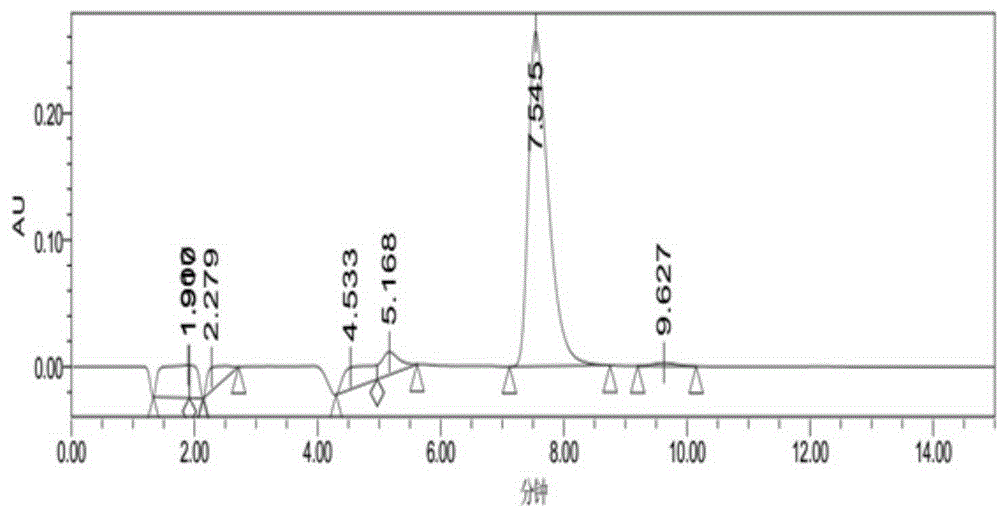

Image

Examples

Embodiment 1

[0020] Embodiment 1: the drawing of the growth curve of wild-type Lactobacillus casei

[0021] Take the wild-type Lactobacillus casei ZW-63A as the starting strain from -80°C, pick it up with a sterilized toothpick and streak it on the YE plate, culture it at a constant temperature of 37°C for 2 days, pick a single clone with a toothpick and inoculate it into 3mL Cultivate overnight in liquid sterile MRS medium, and transfer to 100mL sterilized liquid MRS medium with 1% inoculum size. The bacteria are cultured by standing for 12 hours and then shaking culture. During the culture of bacteria Measure the OD value every 2 hours, dilute the bacterial solution to a certain concentration, control the OD value between 0.1 and 0.9 after dilution, measure the OD value of the bacterial cell at 600nm with an ultraviolet spectrophotometer, and set three parallel repeated experiments , to ensure the credibility of the results. From the growth curve of wild-type Lactobacillus casei, it can...

Embodiment 2

[0022] Example 2: Ultraviolet mutagenesis and breeding of L-lactic acid strains with high optical purity

[0023] Firstly, for the dilution concentration of the bacterial solution during ultraviolet mutagenesis, place the strains cultivated for 18 hours on ice for 10 minutes, then centrifuge at 5000 r / min for 5 minutes at 4°C, discard the supernatant, and use sterilized 0.9% physiological Wash with saline, centrifuge at 5000r / min for 5min at 4°C, discard the supernatant, and wash twice with normal saline. Finally, dissolve the bacteria with 100 mL of sterilized ultrapure water, and fully mix the bacteria. Pipette 100uL of bacterial solution and dilute to 10 -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 、10 -7 、10 -8 、10 -9 、10 -10 For each dilution factor, two parallel plates were set up, and 100uL of each diluted gradient was spread on a YE plate, incubated at a constant temperature of 37°C for 2 days, and then the number of single colonies was calculated.

[0024] Pick th...

Embodiment 3

[0027] Embodiment 3: Carry out mutagenesis selection and stability test to the mutant strain obtained by ultraviolet mutagenesis with diethyl sulfate (DES)

[0028] Put the mutant strain of L-lactic acid with high optical purity screened by ultraviolet mutagenesis on the YE plate, culture it in a constant temperature incubator at 37°C for 2 days, and after the monoclonal growth, use a sterilized toothpick to inoculate the monoclonal colony. In 3mL sterilized liquid MRS medium, cultivate overnight on a shaker at 37°C at 150r / min, transfer to 100mL sterilized liquid MRS medium at a ratio of 1 / 100, and culture at 37°C for 12 hours Shake culture at 150r / min for 20h, then place it on ice for 30min, transfer the bacterial liquid to a sterilized 50mL centrifuge tube in turn in a sterile operating table, centrifuge at 5000r / min for 5min, collect the bacterial precipitate, and use sterilized Bacteria were washed twice with 0.9% normal saline, and finally dissolved with 20mL of 0.9% nor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com