Liquid blast furnace slag granulation and multi-drum waste heat recovery system

A waste heat recovery system and blast furnace slag technology, applied in the field of metallurgy energy conservation and environmental protection, can solve the problems of not realizing double benefits at the same time, and achieve the effect of alleviating the contradiction between the continuity of waste heat utilization, improving the utilization grade, and improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

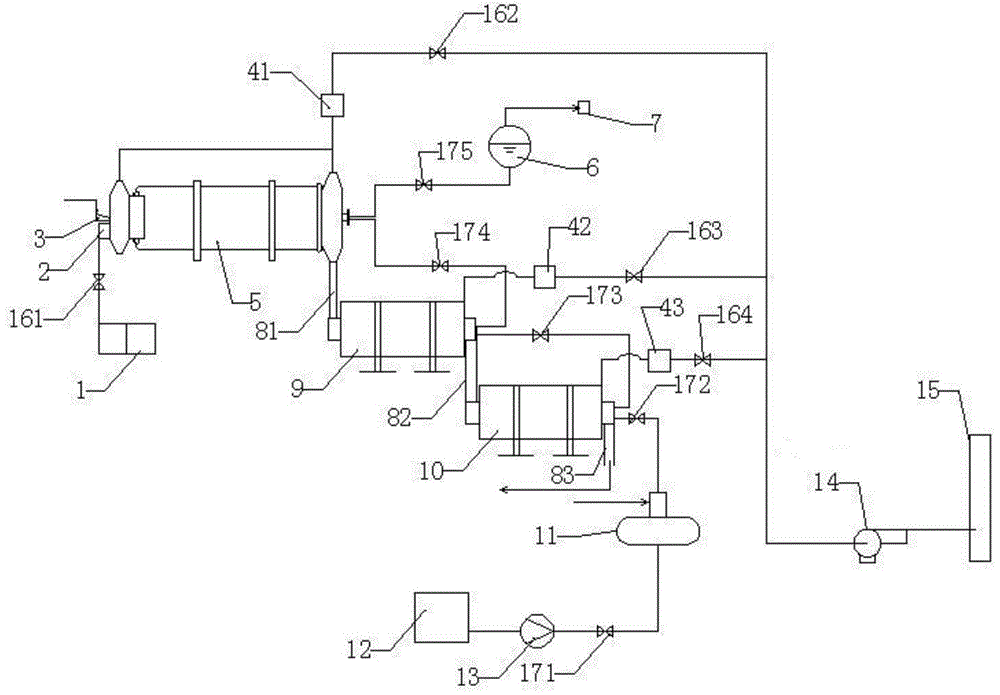

[0022] A liquid blast furnace slag granulation and multi-drum waste heat recovery system uses high-pressure gas to crush the blast furnace slag, and uses multi-stage series drums to cool down the slag particles in steps and recover waste heat.

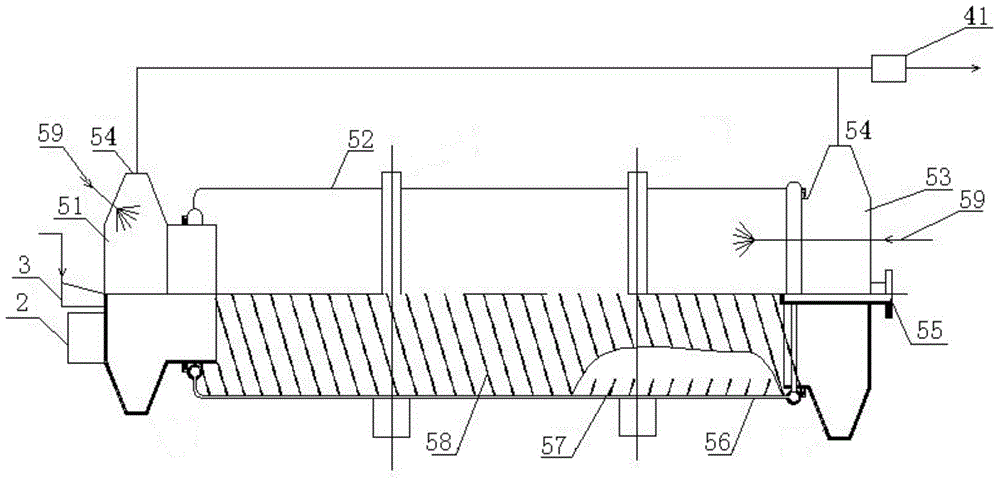

[0023] The structure of this embodiment is as figure 1 As shown, it includes a three-stage series drum, an exhaust cotton collection system, and a waste heat recovery system, wherein the three-stage series drum includes a first-stage vaporization drum granulation bin 5, a second-stage vaporization drum storage bin 9, and a third-stage drum cooler 10; The discharge port of the vaporization drum granulation bin 5 communicates with the feed port of the secondary vaporization drum storage bin 9 through the feed pipe, and the discharge port of the secondary vaporization drum storage bin 9 communica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com