Preparation method of mussel jerky product

A technology for dried mussel meat and mussel meat, which is applied in food preparation, food denaturation, food ingredients, etc. It can solve the problem of strong fishy smell of mussels, unfavorable large-scale processing, and large difference in quality of mussel meat skirts, etc. problem, to achieve the effect of delicious taste, proper chewing force and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

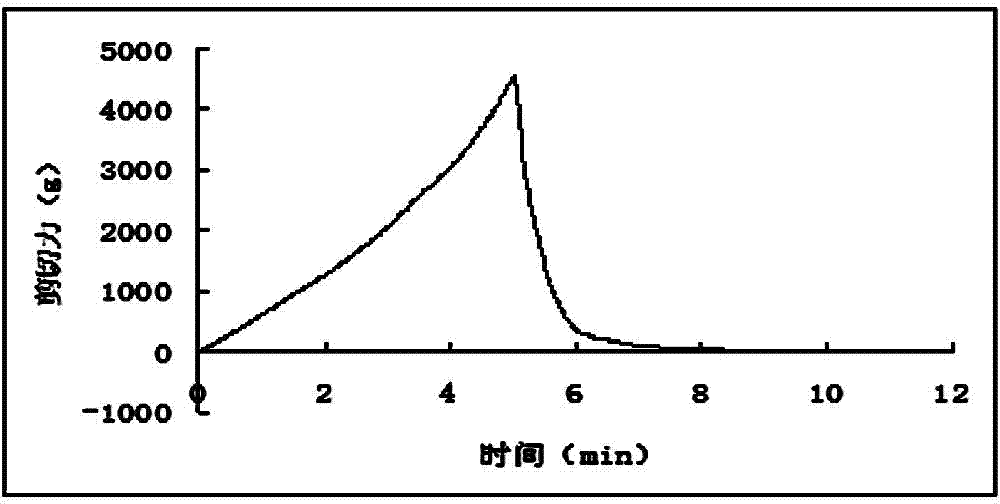

Image

Examples

Embodiment 1

[0030] A kind of preparation method of mussel jerky, its preparation method comprises the following steps:

[0031] (1) Preparation of clam meat homogenate:

[0032] Add 250ml of water into a 1000ml beaker with a measuring cylinder, weigh 0.12g of carrageenan on an electronic balance, add the above water while stirring, heat on an adjustable electric stove, stir while heating until boiling, keep boiling for 3min, until The carrageenan is completely dissolved, the solution is transparent, the concentration of the carrageenan solution is 4.8%, and it is cooled to room temperature for subsequent use.

[0033] Take 400g of mussels, remove the shells and wash them, and get 250g of mussel meat, put them in a tissue masher, add 250ml of carrageenan solution, turn on the tissue masher, and beat for 3 minutes;

[0034] (2) Preparation of mussel meat gel:

[0035] Add 40ml of water into a 100 ml beaker with a measuring cylinder, weigh 10g of glucono δ lactone on an electronic scale, a...

Embodiment 2

[0043] A kind of preparation method of mussel jerky, its preparation method comprises the following steps:

[0044] (1) Preparation of clam meat homogenate:

[0045] Add 25 kg of water into the electric cooking pot, weigh 120g of carrageenan on an electronic scale, add the above water while stirring, turn on the power, stir while heating until boiling, keep boiling slightly for 3 minutes, until the carrageenan is completely dissolved, and the solution It is transparent, the concentration of carrageenan solution is 4.8%, and it is cooled to room temperature for later use.

[0046] Take 40 kg of mussels, remove the shells and wash them, and get 25 kg of mussel meat, put them in a high-speed beater, add 25 kg of carrageenan solution, turn on the high-speed beater, and beat for 3 minutes;

[0047] (2) Preparation of mussel meat gel:

[0048] Add 400ml of water into a 100ml beaker with a measuring cylinder, weigh 100g of glucono δ lactone on an electronic scale, add it into the a...

Embodiment 3

[0056] A kind of preparation method of mussel jerky, its preparation method comprises the following steps:

[0057] (1) Preparation of clam meat homogenate:

[0058] Add 25 kg of water into the electric cooking pot, weigh 150g of carrageenan on an electronic scale, add the above water while stirring, turn on the power, stir while heating until boiling, keep boiling slightly for 3 minutes, until the carrageenan is completely dissolved, and the solution It is transparent, the concentration of carrageenan solution is 6.0%, and it is cooled to room temperature for later use.

[0059] Take 40 kg of mussels, remove the shells and wash them to obtain 25 kg of mussel meat, put them in a high-speed beater, add 25 kg of carrageenan solution, turn on the high-speed beater, and beat for 2.5 minutes;

[0060] (2) Preparation of mussel meat gel:

[0061] Add 800ml of water into a 100ml beaker with a measuring cylinder, weigh 200g of glucono δ lactone on an electronic scale, add the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com