Method for synthesizing branched chain amino acid nitrate

A synthesis method and amino acid technology are applied in the field of synthesizing branched-chain amino acid nitrates, which can solve the problems that branched-chain amino acids are not easily absorbed by the body, and that branched-chain amino acids are not easy to store, package and transport, and achieve qualified product quality and simple steps. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

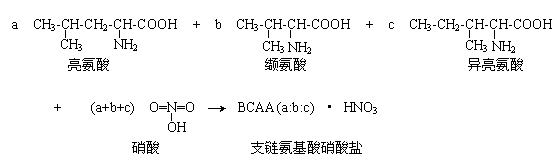

[0024] A kind of synthetic method of mixed branched-chain amino acid nitrate, comprises the steps:

[0025] a. Add nitric acid into the reaction vessel, slowly heat up to 50°C under stirring, add leucine, and keep warm for 0.5 hours to completely dissolve the leucine;

[0026] b. Heat up to 60°C again, add valine, and keep warm for 0.5 hours to dissolve all valine;

[0027] c. Then heat up to 70°C, add isoleucine, and keep warm for 0.5 hours to completely dissolve the isoleucine;

[0028] d. Filtrate the above-mentioned reacted solution, cool the filtrate to crystallize, separate the crystalline product and dry it at -0.09Mpa, 80°C to obtain a solid product of mixed branched-chain amino acid nitrate.

[0029] The molar ratio of the added amount of leucine, valine and isoleucine is 3:2:1.

[0030] The molar ratio of the added amounts of leucine, valine and isoleucine is 2:1:1.

[0031] The ratio of the moles of the added nitric acid to the sum of the moles of leucine, valine...

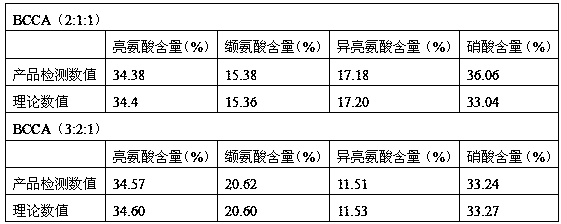

Embodiment 1

[0034] A kind of synthetic method of mixed branched-chain amino acid nitrate, comprises the steps:

[0035] a. Add 77.5kg of concentrated nitric acid with a mass fraction of 65% in the reaction vessel, slowly heat up to 50°C under stirring, add 52.5kg of leucine, and keep warm for 0.5 hours to completely dissolve the leucine;

[0036] b. Heating up to 60°C again, adding 23.4 kg of valine, and incubating for 0.5 hour, so that all valine was dissolved;

[0037] c. Then heat up to 70°C, add 26.2 kg of isoleucine, and keep warm for 0.5 hours to dissolve all the isoleucine;

[0038] d. Filtrate the above-mentioned reacted solution, cool the filtrate to crystallize, separate the crystalline product and dry it at -0.09Mpa, 80°C to obtain 144kg of solid product of mixed branched-chain amino acid nitrate, with a yield of 94.4%.

Embodiment 2

[0040] A kind of synthetic method of mixed branched-chain amino acid nitrate, comprises the steps:

[0041] a. Add 295kg of concentrated nitric acid with a mass fraction of 65% in the reaction vessel, slowly heat up to 50°C under stirring, add 200kg of leucine, and keep warm for 0.5 hours to completely dissolve the leucine;

[0042] b. Heating up to 60°C again, adding 89 kg of valine, and incubating for 0.5 hours, so that all valine is dissolved;

[0043] c. Heat up to 70°C again, add 100 kg of isoleucine, and keep warm for 0.5 hours to completely dissolve the isoleucine;

[0044] d. Filtrate the solution through the above reaction, the filtrate is cooled and crystallized, and the crystal product is separated and dried at -0.09Mpa and 80°C to obtain 556kg of solid product of mixed branched-chain amino acid nitrate, with a yield of 95.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com