Microspheric Fischer-Tropsch synthesized iron and zinc catalyst and preparation method and application of microspheric Fischer-Tropsch synthesized iron and zinc

A technology of Fischer-Tropsch synthesis and catalysts, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. It can solve problems such as easy overheating, low selectivity of heavy hydrocarbons, and difficulty in removing heat from reactions , to achieve the effect of promoting dispersion and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

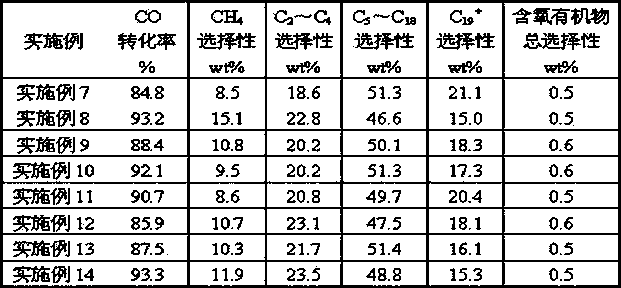

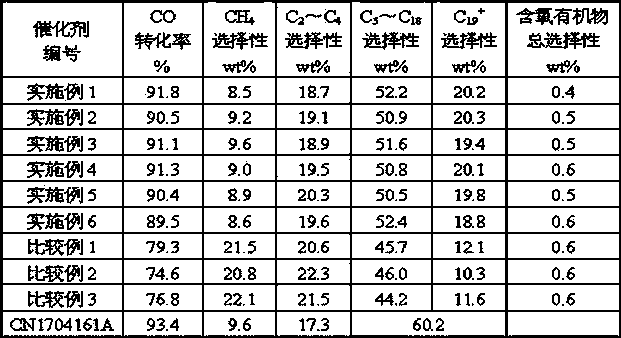

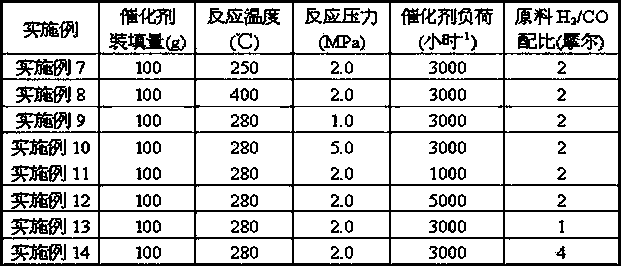

Examples

Embodiment 1

[0031] Add 20 grams of water to 3.83 grams of Potassium Hydroxide and dissolve after heating to obtain material (A); 461.7 grams of ferric nitrate and 33.99 grams of zinc nitrate are placed in the same container, add 120.2 grams of manganese nitrate, and then add 400 grams of water, stir and dissolve to obtain material (B).

[0032] Material (A) is mixed with 625 grams of silica sol with a weight concentration of 40%, and material (B) is added successively under stirring, and the acidity of the above-mentioned slurry is adjusted with ammonia water so that the pH=6.0 of the mixed slurry is fully stirred to obtain Slurry, according to the usual method, the prepared slurry is carried out into microspheres in a spray dryer, and finally the inner diameter is 89 mm, and the length is 1700 mm (φ89 * 1700 mm) in a rotary roaster at 500 ° C for 2.0 hours, made into:

[0033] 50% Fe 100 K 5.0 mn 30.0 Zn 10.0 o x +50%SiO2 2 .

[0034] catalyst.

[0035] The prepared catalyst was c...

Embodiment 2~6

[0052] Adopt and [embodiment 1] substantially the same method to prepare the catalyst with different composition, gained catalyst number and composition are respectively:

[0053] Example 1 50%Fe 100 K 5.0 mn 30.0 Zn 10.0 o x +50%SiO2 2

Embodiment 2

[0054] Example 2 60%Fe 100 K 8.0 Cu 30.0 mn 20.0 Zn 1.0 o x +40%Al 2 o 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com