Patents

Literature

46results about How to "Resolve volatile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

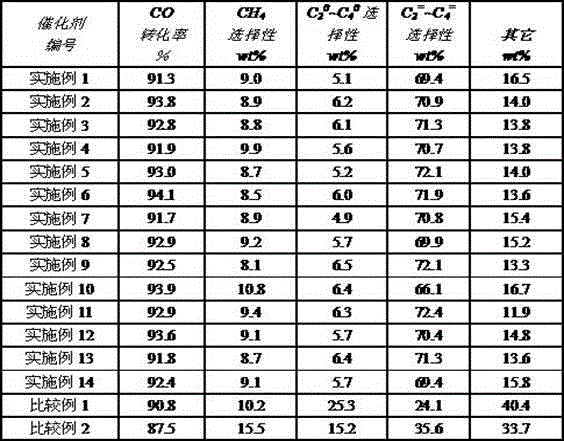

Catalyst for directly preparing low-carbon olefin from microspherical synthesis gas, as well as preparation method thereof

ActiveCN104549296AImprove wear performanceReduce wear rateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasFluidized bed

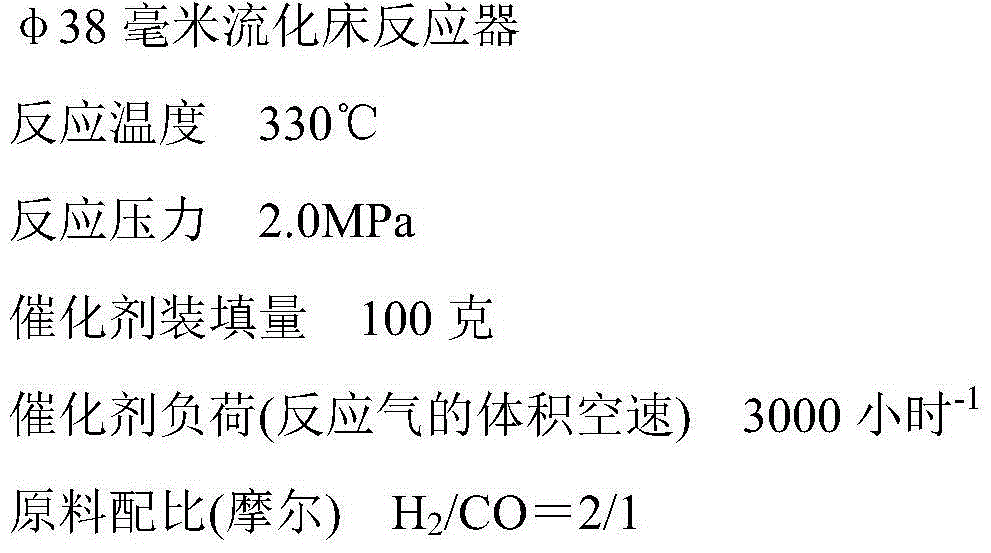

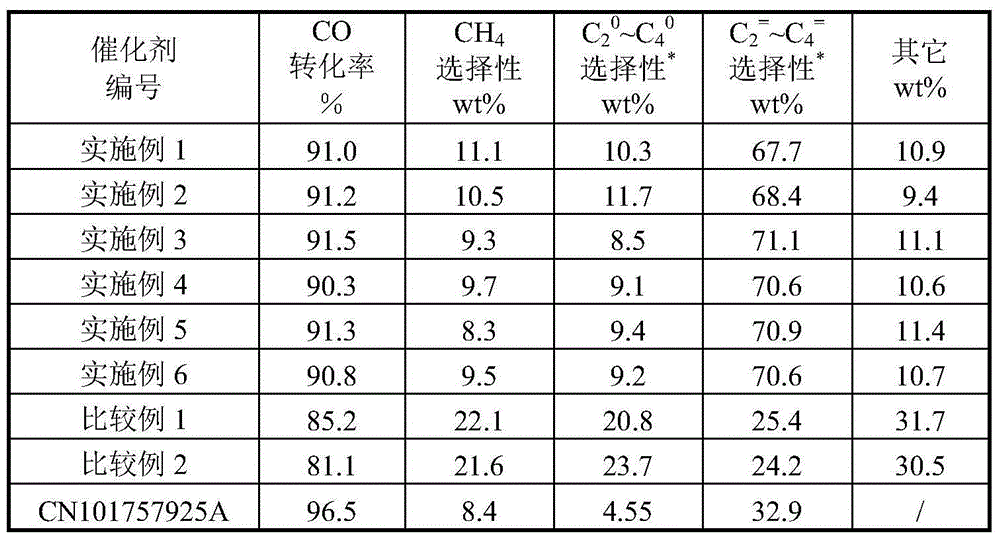

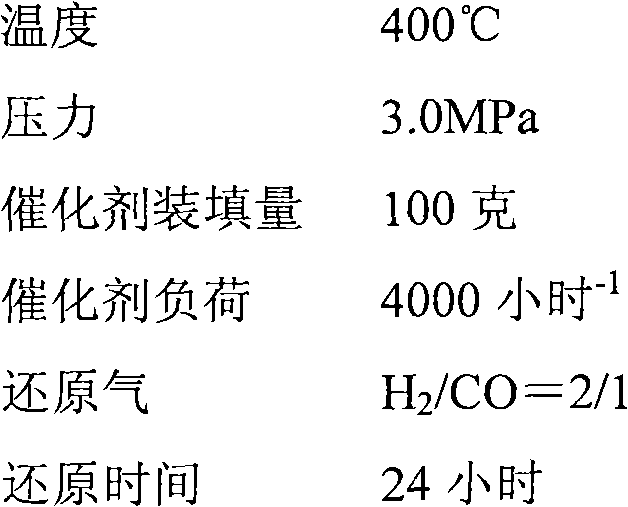

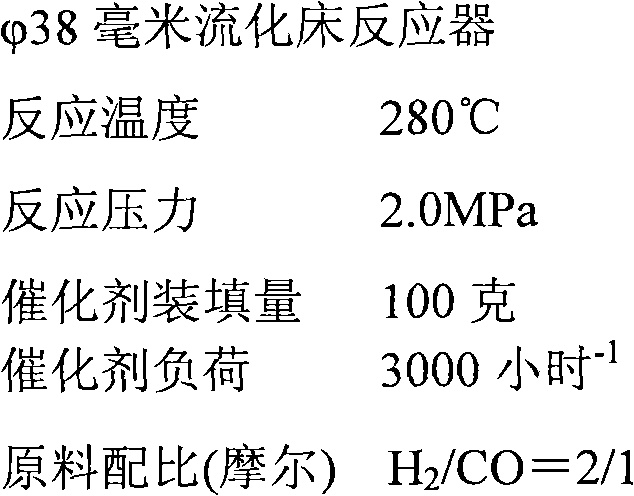

The invention relates to a catalyst for directly preparing a low-carbon olefin from a microspherical synthesis gas, and is mainly used for solving the problems that the existing co-precipitation Fischer-Tropsch catalyst preparation technology comprises the following steps: firstly co-precipitating and then pulping and spray-forming, so that the slurry is substantially a non-homogenous body dispersed by adopting a physical method, the finial catalyst finished product is uneven and the hydrocarbon products on the catalyst are widely distributed. The problems are well solved by adopting the technical scheme that the preparation method comprises the following steps: firstly precipitating a part of components, then carrying out peptization on the obtained precipitates by using the salt solution of non-precipitated components to obtain chemically evenly dispersed sol, then spray-drying the sol, and then roasting at high temperature. The preparation method can be used for industrial production for a catalyst for synthesizing the low-carbon olefin from the synthesis gas. The catalyst is applicable to but not limited to such reactors as a fluidized bed and a slurry-state bed in which catalyst grains are required to be distributed according to the certain distribution rule.

Owner:CHINA PETROLEUM & CHEM CORP +1

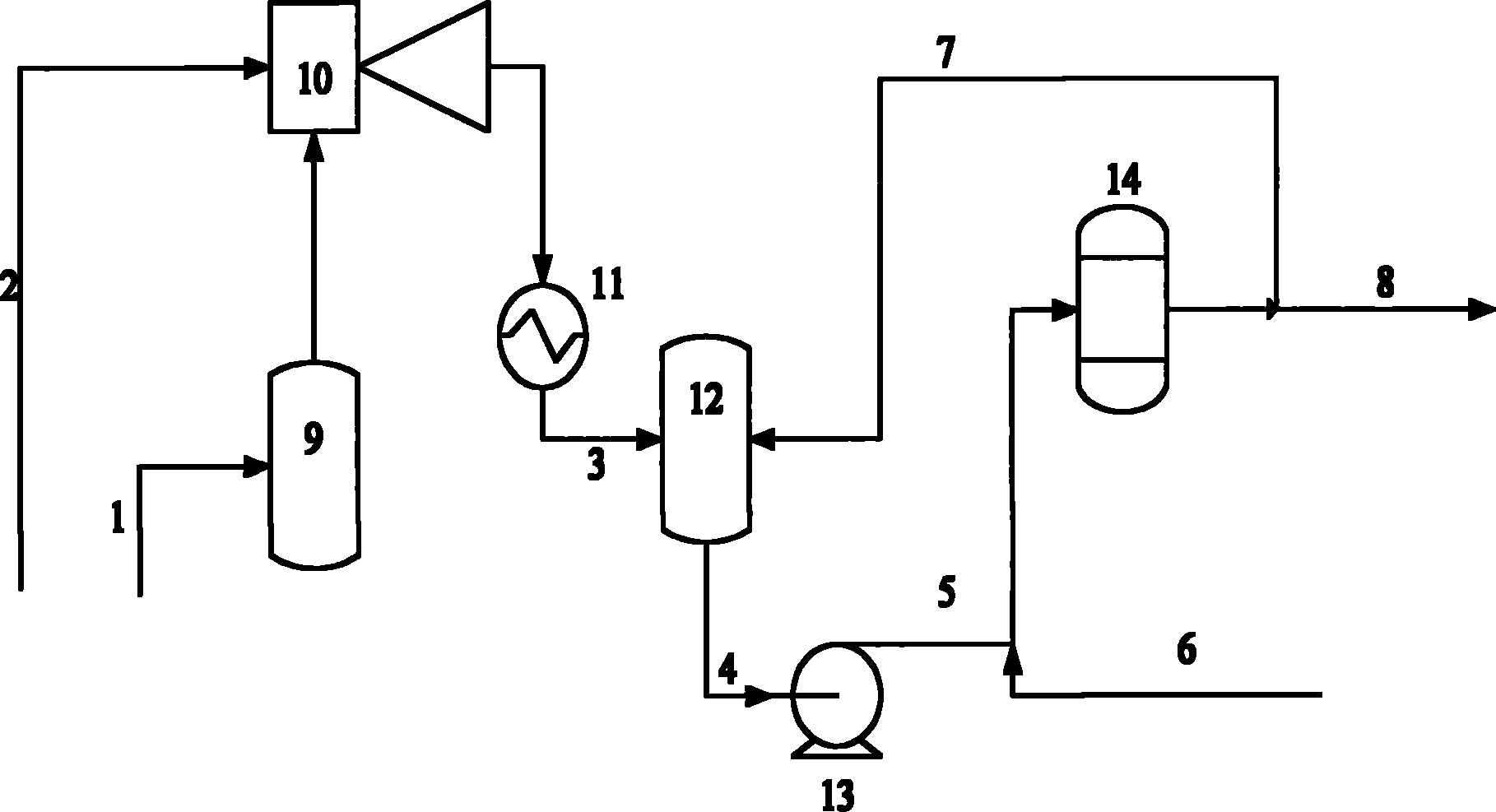

Method for recycling waste gas of butadiene extracting device

ActiveCN102050695AIncrease profitAchieve boostHydrocarbon by hydrogenationHydrocarbon purification/separationAlkaneHigh pressure

The invention discloses a method for recycling waste gas of a butadiene extracting device, which comprises: (1) a step of boosting, which is to allow liquid-phase C4 with a relatively high pressure and the waste gas with a relatively low pressure to enter the injector, mix the waste gas and the liquid-phase C4 at the outlet of the injector to form a gas-liquid phase material flow, and cool the material flow to obtain the liquid-phase blended C4 material flow; and (2) a step of hydrogenization, which is to mix the blended C4 material flow obtained by the step (1) and circular alkane from hydrogenization products, boost with a booster pump, introduce hydrogen gas into the hydrogenization reactor, cool the products discharged from the outlet of the hydrogenization reactor to room temperature, and separate the products into two flows, wherein one flow serving as the circular alkane is introduced to the inlet of the hydrogenization reactor, and the other is used as the alkane product. The method can reduce the inactivation of catalyst in the hydronization process, saves energy and improves the comprehensive utilization rate of C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

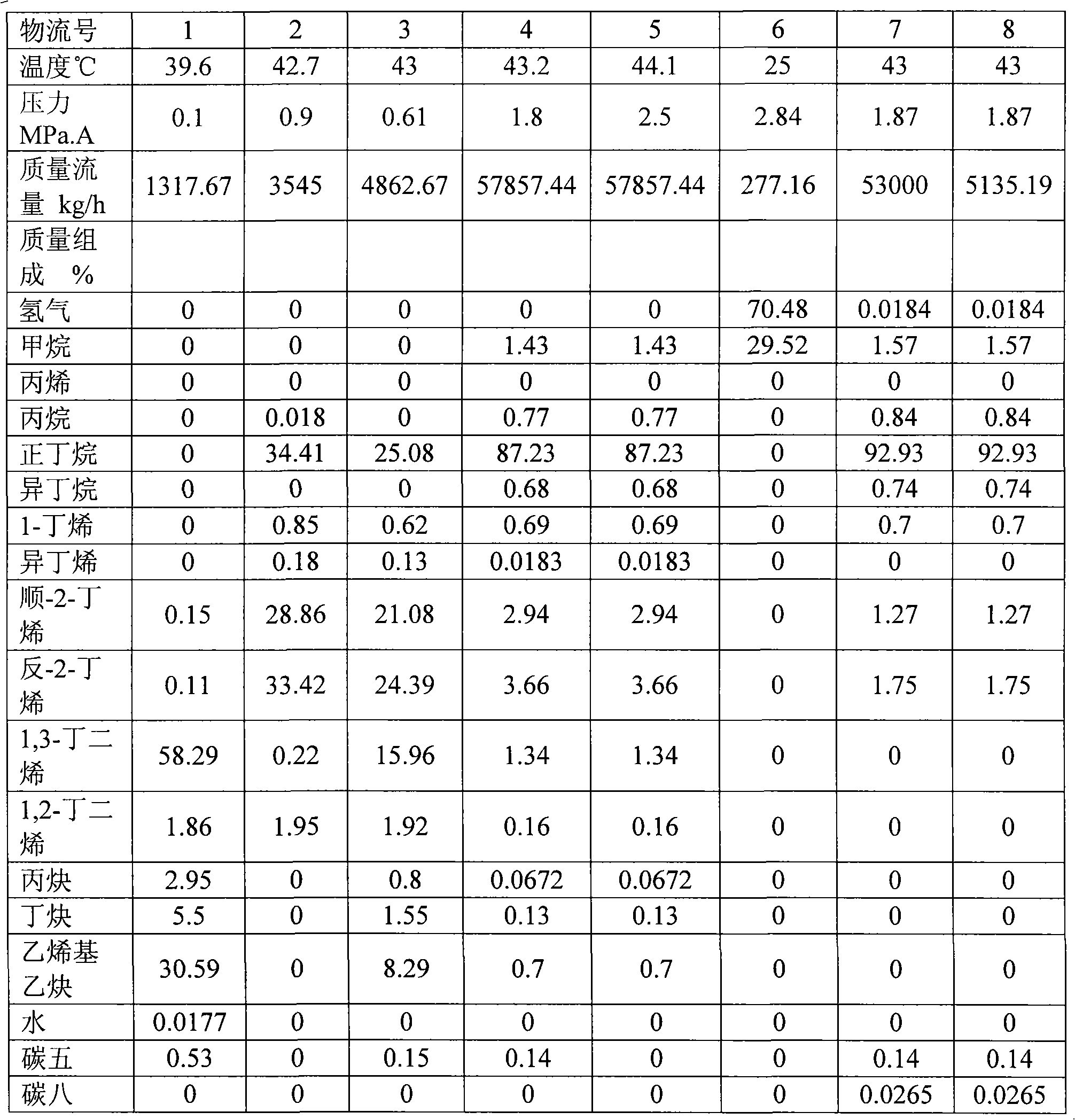

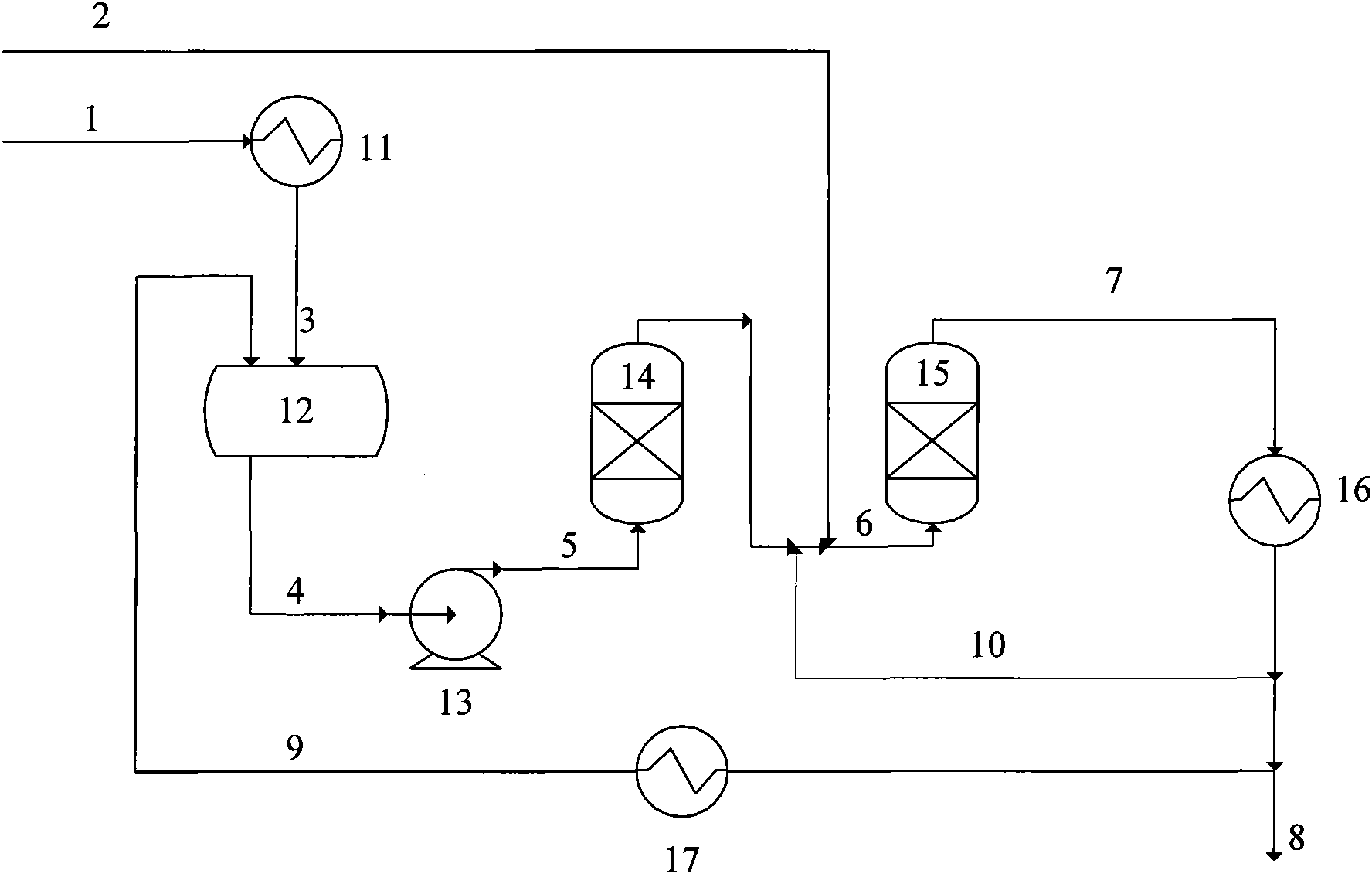

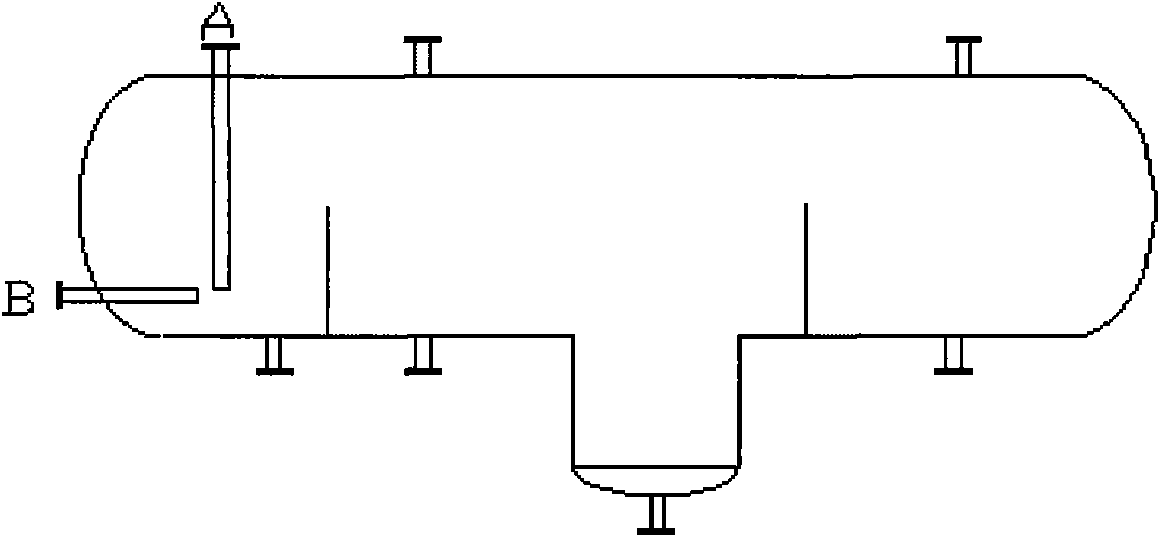

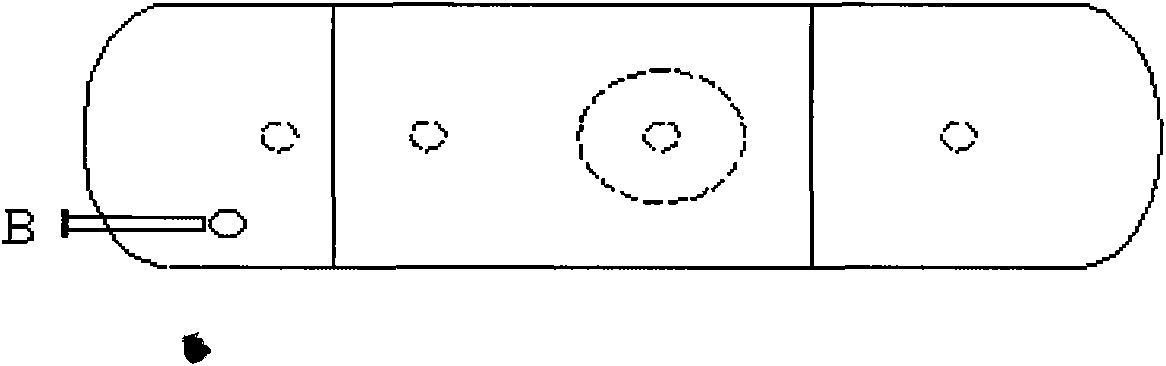

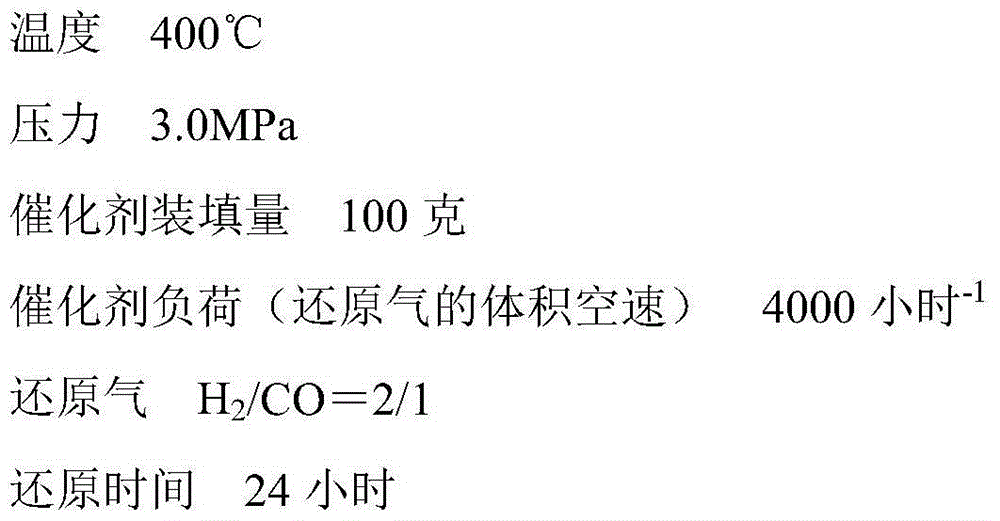

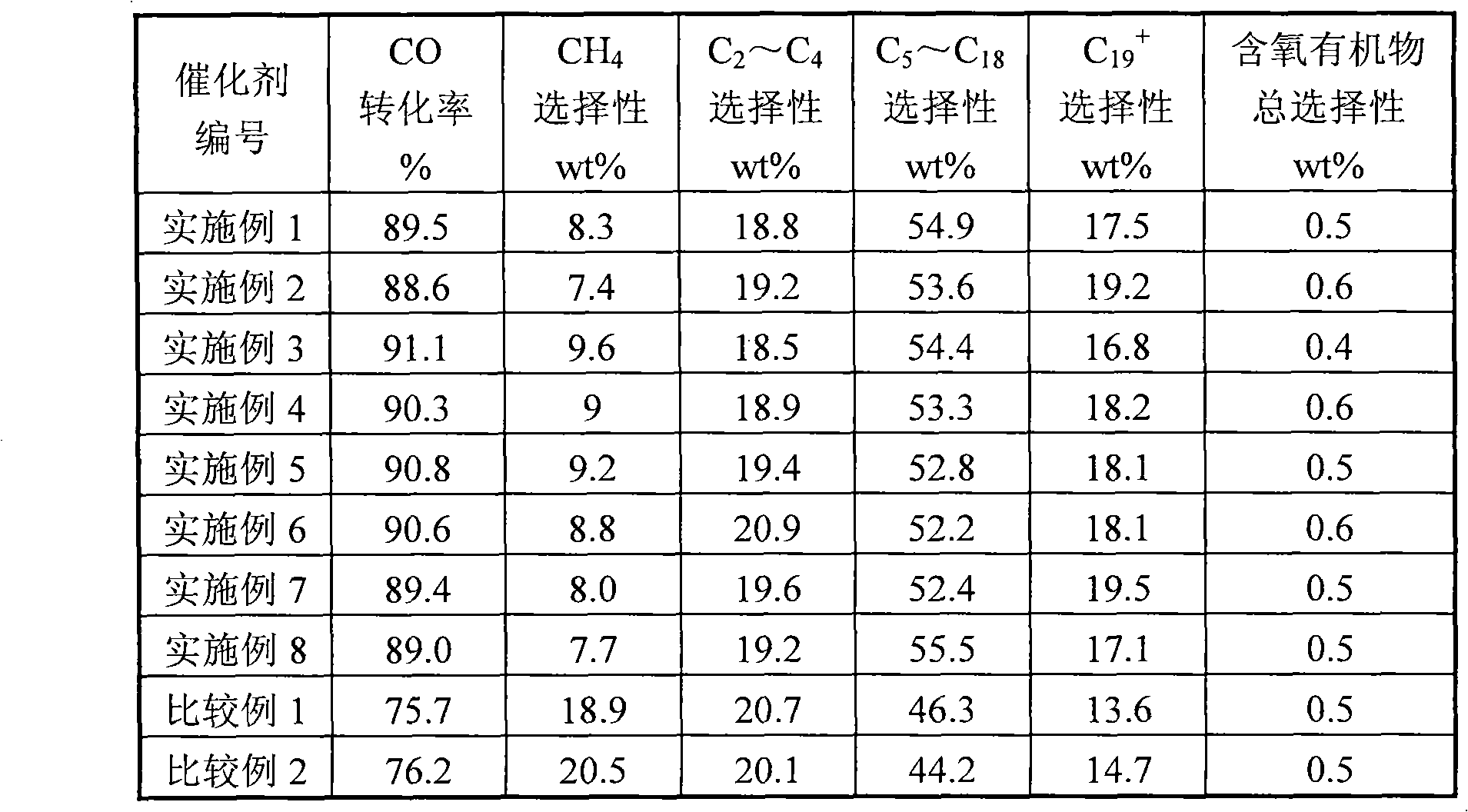

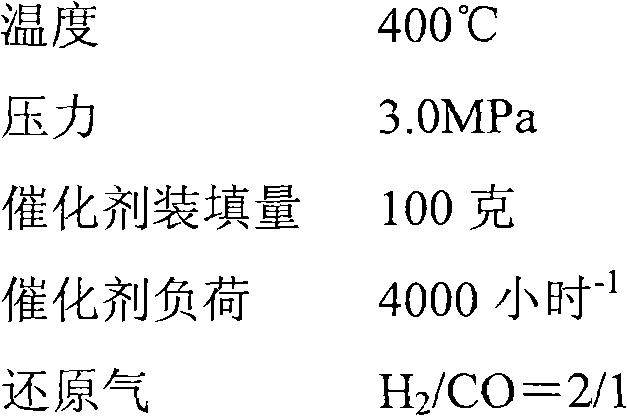

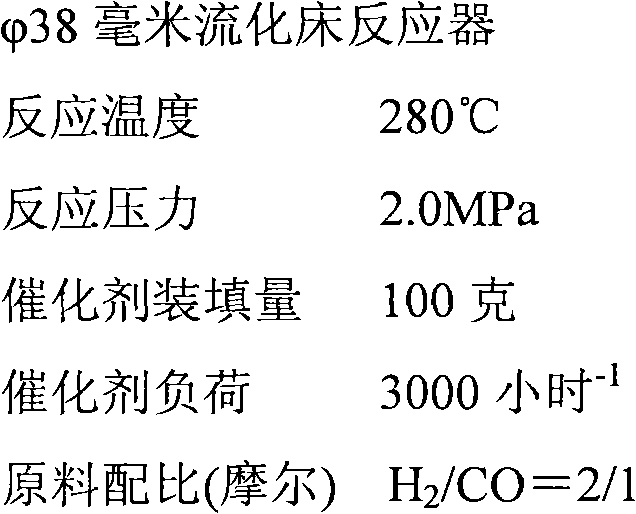

Fischer-Tropsch synthesis method for heavy hydrocarbon

ActiveCN101993707AResolve volatileHigh activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalSynthesis methods

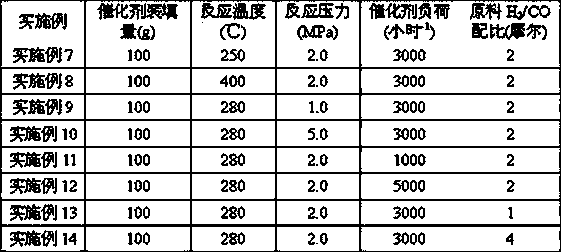

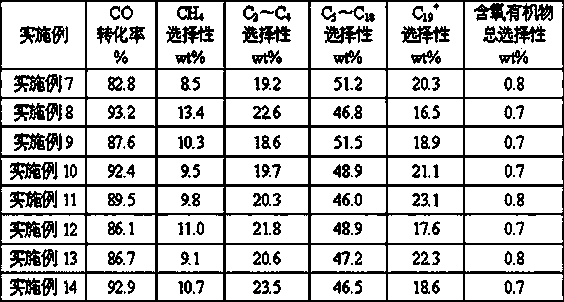

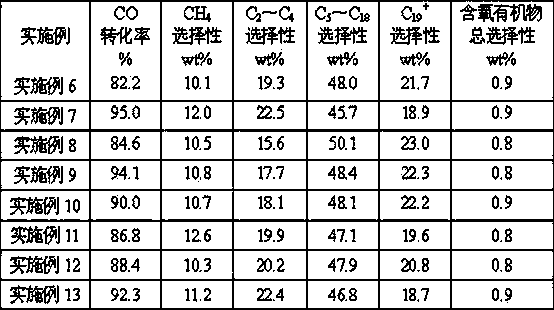

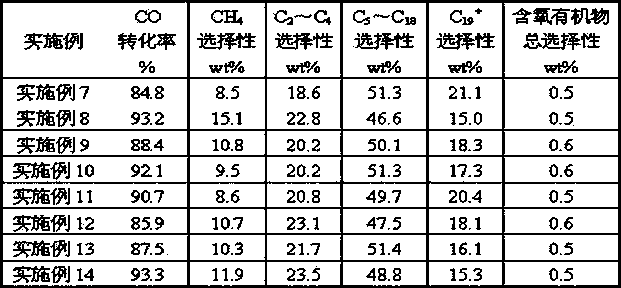

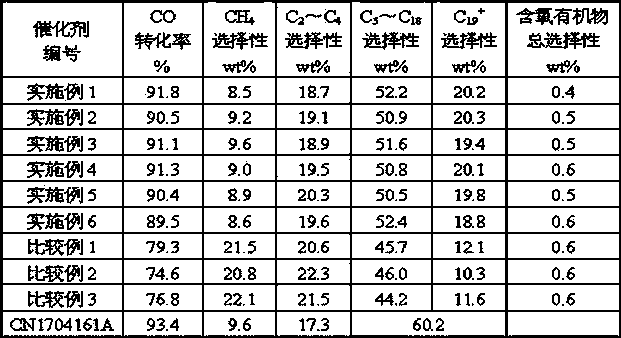

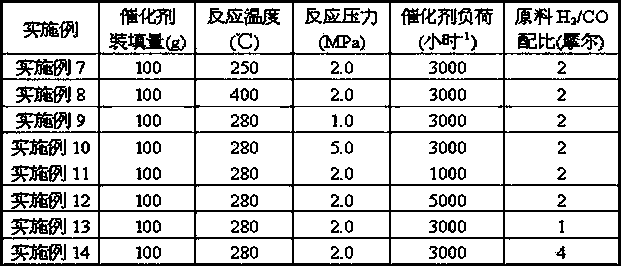

The invention relates to a Fischer-Tropsch synthesis method for heavy hydrocarbon, mainly solving the problems that as the Fischer-Tropsch synthesis reaction is an exothermal reaction, in the prior art, when a fixed bed is used, heat is difficultly removed for reaction and the temperature is easy to run away so that a catalyst is easy to inactivate; and when a fluidized bed is used, the selectivity of the heavy hydrocarbon is low. In the Fischer-Tropsch synthesis method, a synthesized gas is taken as a raw material; and the raw material is contacted and reacted with a fluidized bed catalyst at the conditions of 0.5-10MPa of pressure, 200-600 DEG C of reaction temperature and 100-8000 h<-1> of reaction air speed, so as to generate the heavy hydrocarbon, wherein the used iron-based fluidized bed catalyst takes at least one oxide selected from Si or Al as a carrier; and an active component contains a composition having the chemical formula based on an atom ratio as follows: Fe100AaBbCcOx, wherein A is selected from at least one of alkali metals or alkaline-earth metals, B is selected from at least one of La or Ce, and C is selected from at least one of Cu or Mn. By using the technical scheme of the method, the problems can be better solved. The method can be used in industrial production of Fischer-Tropsch synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

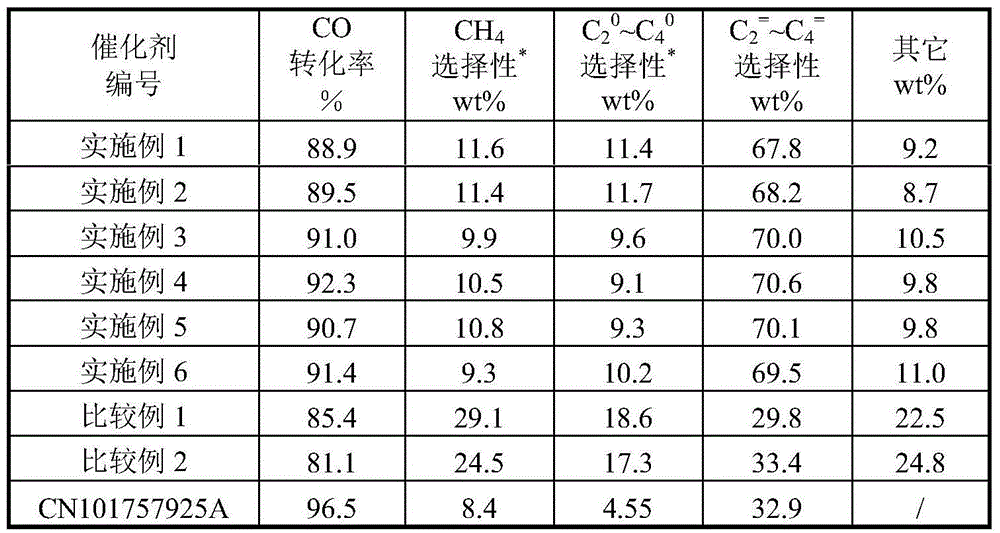

Catalyst for directly preparing light hydrocarbon through synthesis gas and preparation method of catalyst

ActiveCN105363464ALow selectivityHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasActive component

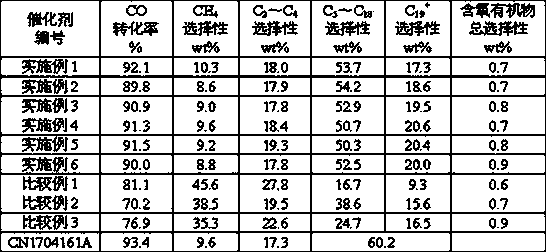

The invention relates to a catalyst for directly preparing light hydrocarbon through synthesis gas and a preparation method of the catalyst. The problem that in the prior art, light hydrocarbon is low in selectivity is mainly solved. Through the technical scheme that synthesized gas as the raw material makes contact with the iron-base fluidized bed catalyst, with the composition of chemical formula of Fe100KaCobMncLadOx as the active component according to the atomic ratio, in a fluidized bed at the pressure of 0.5-10 MPa, the reaction temperature of 200-600 DEG C, the reaction airspeed of 100-8000 h<-1> and the raw material gas H2 / CO ratio of 0.1-5.0 to 1.0 with alumina as the carrier to react and generate light hydrocarbon, the problems are well solved, and the catalyst can be used for industrial production of directly preparing light hydrocarbon through synthesis gas in the fluidized bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

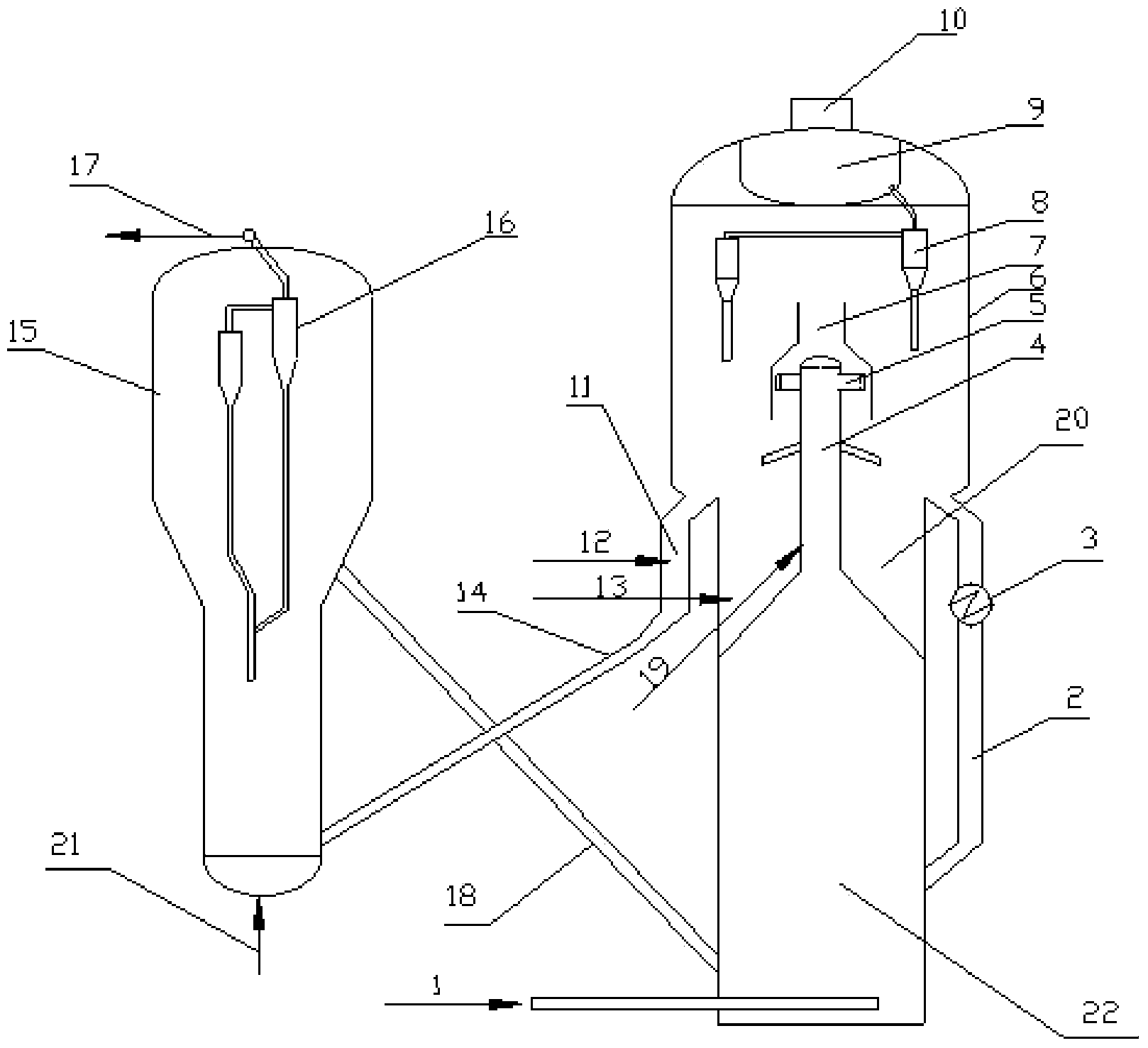

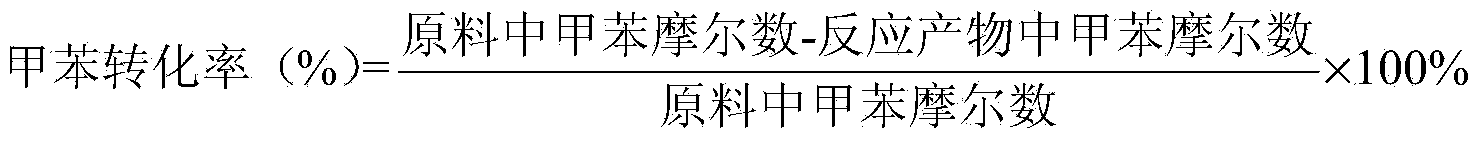

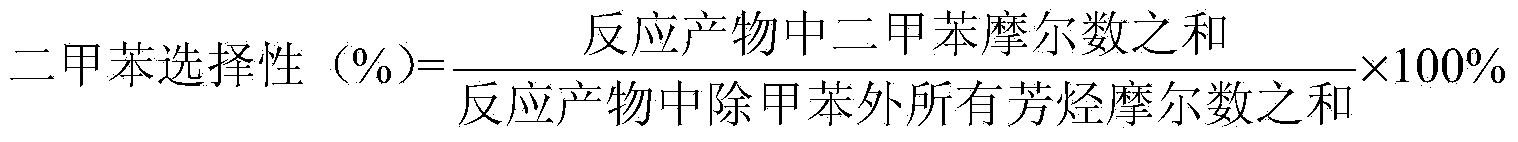

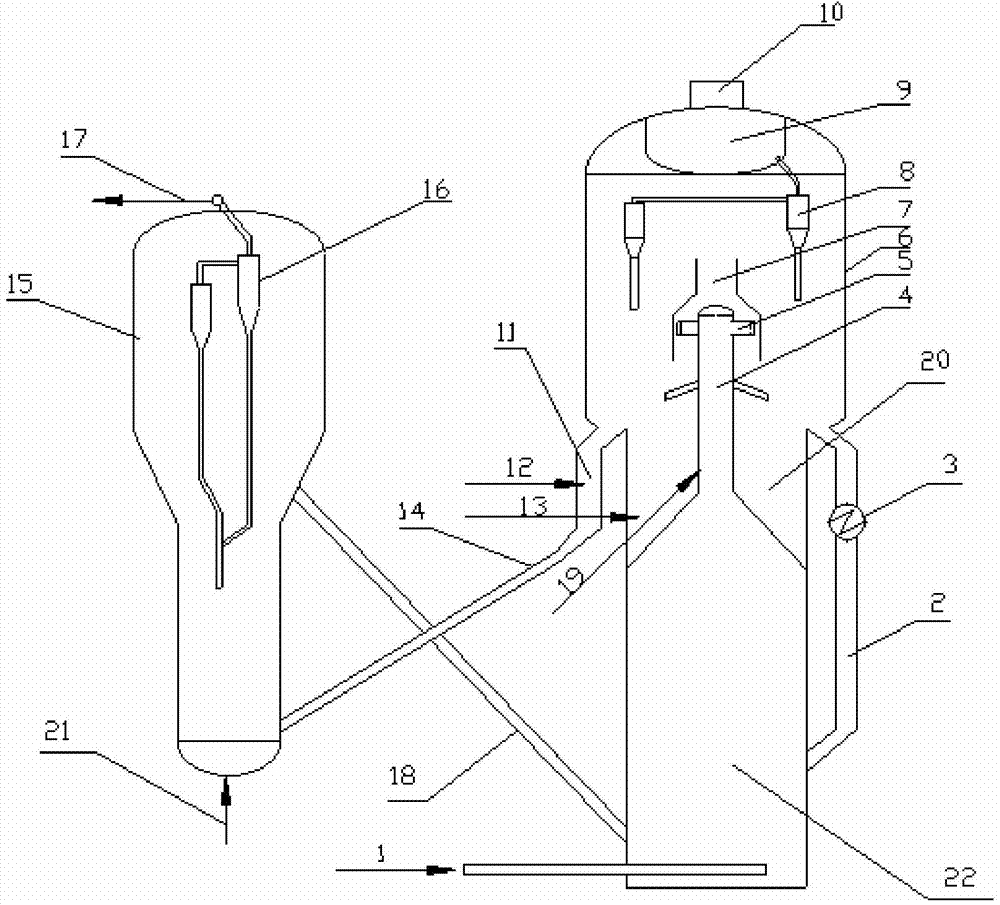

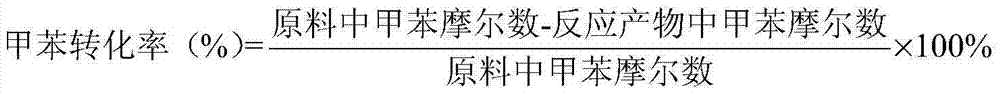

Fluidized bed method for producing p-xylene through shape-selective toluene and methanol alkylation

ActiveCN103588601ALow selectivityReduce temperature riseHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical recyclingAlkyl transferGas phase

The invention relates to a fluidized bed method for producing p-xylene through shape-selective toluene and methanol alkylation, and mainly solves the problem of lower selectivity for p-xylene in the prior art. The fluidized bed method for producing the p-xylene through the shape-selective toluene and methanol alkylation comprises the steps as follows: 1), raw materials enter a reaction zone of a fluidized bed reactor after heated and are contacted with an alkylation catalyst, and a mixture flow of the p-xylene is generated; 2), the mixture flow enters a rapid gas-solid separation zone, a separated gaseous product enters a follow-up separation section, a separated catalyst enters a toluene pre-contact region, at least one part of the catalyst in the toluene pre-contact region enters a regenerator for regeneration after steam stripping by a steam stripping zone, and a regenerated catalyst is formed; and 3), the regenerated catalyst returns to the reaction zone for continuous reaction. With the adoption of the technical scheme, the problem is solved, and the method can be applied to p-xylene production.

Owner:SHANGHAI HUAYI GRP CO

Method and equipment for using waste gas of butadiene extraction unit

ActiveCN101993323AIncrease profitAlkyne content decreasedHydrocarbon by hydrogenationGaseous mixture working upAlkaneNaphtha

The invention relates to a method for using waste gas of a butadiene extraction unit, comprising the following steps: (1) condensation and pressurization: introducing waste gas materials from the extraction unit to a condenser, condensing the materials to liquid phases to enter a mixing tank, completely mixing the liquid phases with diluted alkane from hydrogenated products of step (2) in the mixed tank, then entering to a pump, pressurizing by the pump; and (2) hydrogenation: mixing the mixed material flow pressurized in step (1) with cycling alkane from hydrogenated products, adding hydrogen in a certain ratio and then entering a hydrogenation reactor, cooling the hydrogenated products at the outlet of the reactor to normal temperature, and dividing the cooled products into three parts,wherein one part is taken as diluted alkane to enter the mixed tank in step (1), one part is taken as cycling alkane to enter inlet of the reactor, and the rest part is served as alkane products. Thehydrogenated products in the invention can be taken as the fuels, can be returned to a cracking furnace as cracking stocks to replace parts of naphtha, and also can be taken as high-purity alkane which is sent to a downstream unit for being a raw material, thereby reaching the purposes of saving resources and improving the rate of multipurpose utilization of C4.

Owner:CHINA PETROLEUM & CHEM CORP +1

A microsphere catalyst for preparing lower hydrocarbons from synthetic gas and a preparing method of the catalyst

ActiveCN105435803AResolve volatileLow selectivityHydrocarbon from carbon oxidesCatalyst activation/preparationMicrosphereActive component

The invention relates to a microsphere catalyst for preparing lower hydrocarbons from synthetic gas and a preparing method of the catalyst, and mainly overcomes problems in the prior art that reaction heat dissipation is difficult when fixed beds are used, and temperature runaway can easily arise so that catalysts are liable to deactivate because reactions of synthesizing the lower hydrocarbons from the synthetic gas are strongly exothermal reactions and a problem that selectivity of lower hydrocarbons especially lower olefins is low. According to a technical scheme, an iron-based fluidized bed catalyst adopting aluminium oxide as a carrier and adopting an active component comprising a composition is adopted, with the chemical formula based on an atomic ratio being shown as Fe<100>KaZnCr<c>La<d>Ox, the synthetic gas is adopted as a raw material, and the raw material is brought into contact with the iron-based fluidized bed catalyst in a fluidized bed and reacts to produce the lower hydrocarbons. The problems are overcome by adoption of the technical scheme. The catalyst can be used for industrial synthesis of the lower hydrocarbons from the synthetic gas in fluidized beds.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized bed Tropsch synthesis method for heavy hydrocarbons

ActiveCN102041020AResolve volatileLow selectivityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalSynthesis methods

The invention relates to a Tropsch synthesis method for heavy hydrocarbons, which mainly solves the problems that the reaction heat dissipation is difficult, temperature runaway is easily caused and the catalyst is easily inactivated when a fixed bed is used and the selectivity of the heavy hydrocarbons is low when a fluidized bed is used in the prior art because the Tropsch synthesis reaction is strong heat generating reaction. Synthesis gas is used as a raw material; under the conditions that the reaction pressure is 0.5 to 10MPa, the reaction temperature is 200 to 600 DEG C, the reaction space velocity is 100 to 8,000 per hour and the H2 / CO molar ratio of the raw material gas is 0.1-5.0: 1, the raw material is contacted with a cobalt-based fluidized bed catalyst in the fluidized bed and reacted to generate the heavy hydrocarbons, wherein the heavy hydrocarbons are hydrocarbons of over C5; and in the cobalt-based fluidized bed catalyst, at least one of oxides of Si and Al or mixture of Si or Al and ZrO2 is selected as a carrier, and the active ingredient contains the following compound with chemical formula in an atomic ratio: Co100AaBbOx, wherein in the formula, A is selected from at least one of alkali metals or alkaline earth metals, and B is selected from at least one of Cr, Ni, Cu and Zn. According to the technical scheme, the problems are well solved, and the method can be used in the industrial production of fluidized bed Tropsch synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch synthesized Co-based fluidized bed catalyst and preparation method thereof

ActiveCN102039133AHigh mechanical strengthReduce wear rateCatalyst activation/preparationLiquid hydrocarbon mixture productionAlkaline earth metalFluidized bed

The invention relates to a Fischer-Tropsch synthesized Co-based fluidized bed catalyst and a preparation method thereof, mainly solving the problems existing in the prior art because an Fischer-Tropsch synthesis reaction is a strong exothermic reaction which causes thermal withdrawal difficulty in a reactor, temperature runaway and easy catalyst inactivation in case of using a fixed bed, and relatively low selectivity of heavy hydrocarbon in case of using a fluidized bed. By adopting the preparation method and the technical scheme that at least one of oxides of Si or Al or a mixture of the at least one oxide and ZrO2 is selected as a carrier, and the active constituent contains the following composition with a chemical formula in the atomic ratio of Co100AaBbOx, wherein A is selected from at least one of alkali metal or alkaline earth metal, B is selected from at least one of Cr, Ni, Cu and Zn to be combined into a catalyst, the invention favorably solves the problems and can be used in the industrial production of the Fischer-Tropsch synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-sugar meal-replacement powder for regulating human intestines and preparation method of low-sugar meal-replacement powder

InactiveCN108669438AImprove physiological activityHigh activityFood ingredient as mouthfeel improving agentMicrowave methodAlpha-amylase

The invention discloses low-sugar meal-replacement powder for regulating human intestines and a preparation method of the low-sugar meal-replacement powder and belongs to the field of food processing.The preparation method comprises the following steps: liquefying a mixture of oat powder, millet powder and coix seed powder by using alpha-amylase, performing enzymolysis on proteins by using papainunder assistance of a microwave method, inoculating bacillus coagulans and lactic acid bacteria, mixing to carry out fermentation, implementing a low-temperature spraying drying technique on a fermentation liquid to obtain coarse cereal flour, and mixing the obtained coarse cereal flour with lycium barbarum powder, lotus seed powder, kudzu vine root powder, konjaku flour and a xylitol raw material, thereby obtaining the low-sugar meal-replacement powder. The low-sugar meal-replacement powder disclosed by the invention has the characteristics that the bacillus coagulans and the lactic acid bacteria are adopted as fermentation agents, on the basis that the taste of coarse cereals is improved, rich dietary fibers of the coarse cereals are maintained, and in addition, unique flavor can be achieved.

Owner:JILIN UNIV

Yogurt containing bifidobacterium embedding beads or embedding blocks and preparation method thereof

ActiveCN103749672AResolve volatileActivity does not weakenMilk preparationBiotechnologyBifidobacterium

The invention discloses yogurt containing bifidobacterium embedding beads or embedding blocks and a preparation method thereof and aims to solve the problems that the bifidobacterium in a bifidobacterium drink product is low in activity, short in storage period and difficult to store. The yogurt contains bifidobacterium embedding beads or embedding blocks, and the preparation method is divided into two links, namely preparation of the bifidobacterium embedding beads or embedding blocks, and preparation of the yogurt containing the bifidobacterium embedding beads or embedding blocks. The problems that the bifidobacterium is low in viable count in the yogurt content, the storage period is short, and the bifidobacterium is hard to reach the intestinal tract in batches after being eaten are effectively solved, the viable count of the bifidobacterium, the activity of the bifidobacterium and the storage period of the bifidobacterium are effectively guaranteed, and a probiotic role of the bifidobacterium to a human body is realized. The yogurt containing bifidobacterium embedding beads or embedding blocks is mild in preparation conditions, and the method is simple and convenient and is convenient for industrial production.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

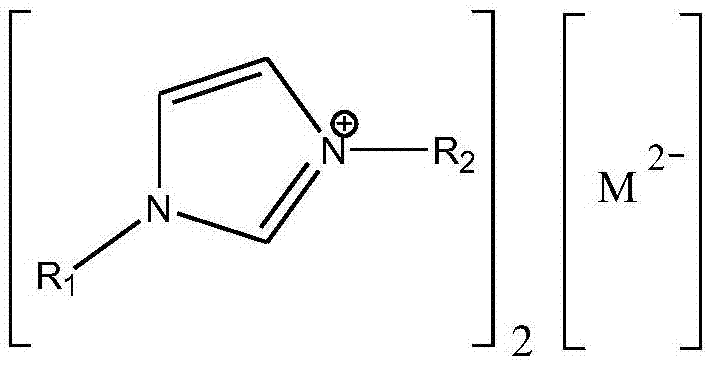

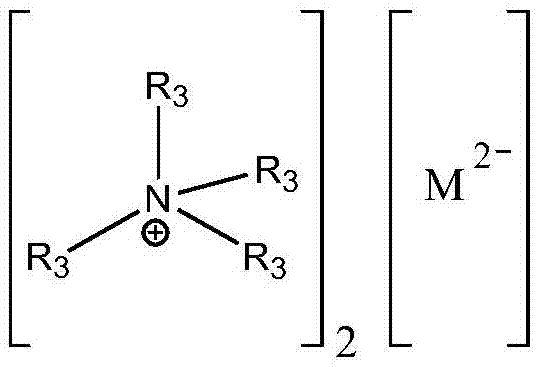

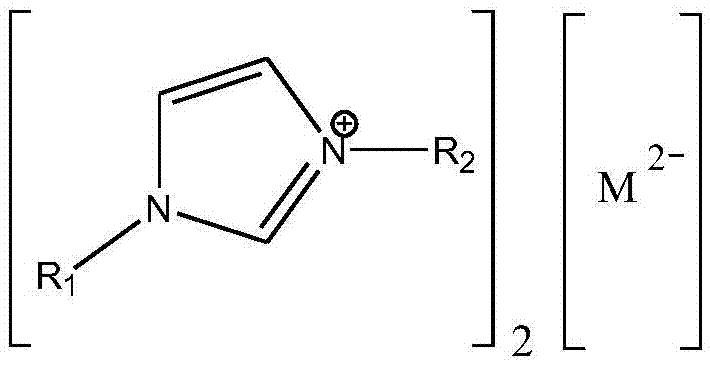

Method for preparing didodecyl carbonate by taking oxometallate ion liquid as catalyst

ActiveCN105439856AHigh catalytic activityMild reaction conditionsPreparation from organic carbonatesIonDistillation

The invention discloses a method for preparing didodecyl carbonate by taking an oxometallate ion liquid as a catalyst. The method comprises: adding dimethyl carbonate, laurinol and the oxometallate ion liquid catalyst into a reaction kettle in sequence; stirring and heating to 80-110 DEG C; performing a constant-temperature reaction for 1-3 hours and cooling; and performing water-washing, phase-splitting and reduced pressure distillation separation to obtain didodecyl carbonate. According to the method, the oxometallate ion liquid catalyst is high in catalytic activity, the reaction condition is mild, the highest conversion rate of dimethyl carbonate reaches 99%, and the yield of the didodecyl carbonate reaches 97%; and in addition, the oxometallate ion liquid catalyst is simple to synthesize and high in stability, can be reused after water-washing and drying treatment, and still can keep relatively high catalytic activity after being used for multiple times, so that the problems that an existing solid base catalyst is complicated in preparation and liable to lose activity are solved.

Owner:JIANGXI NORMAL UNIVERSITY

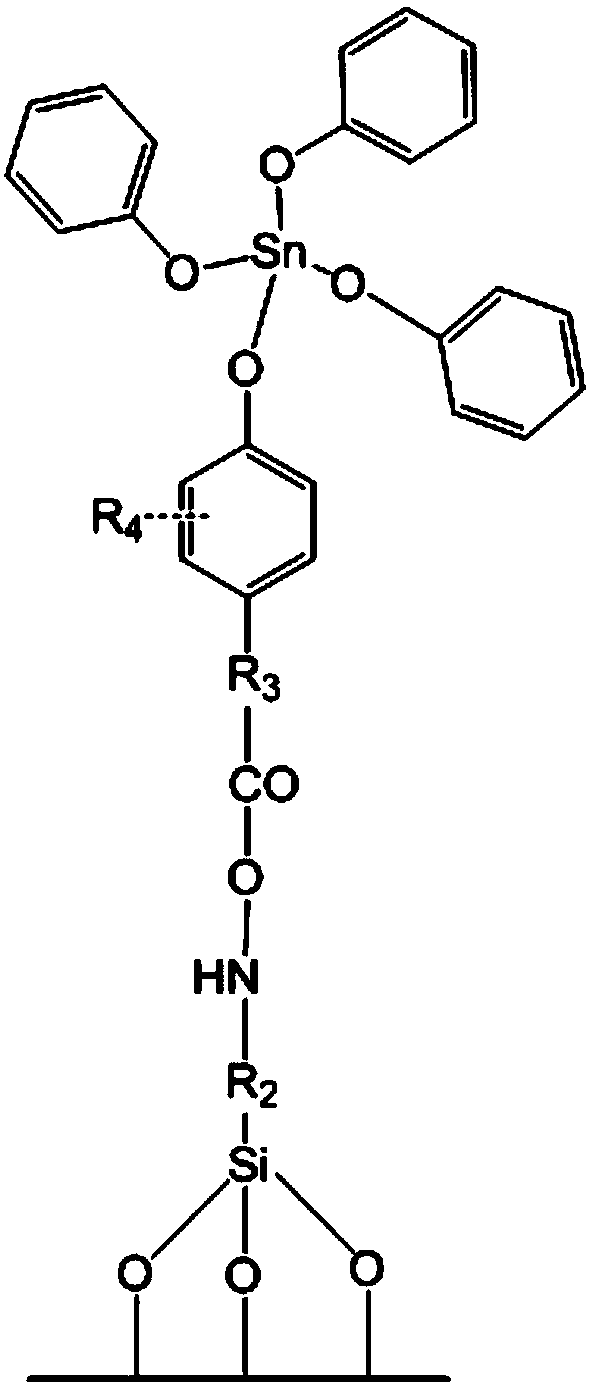

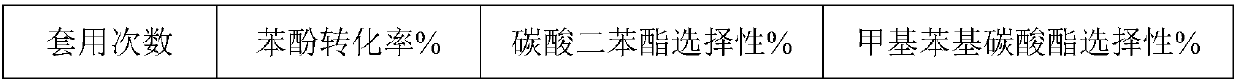

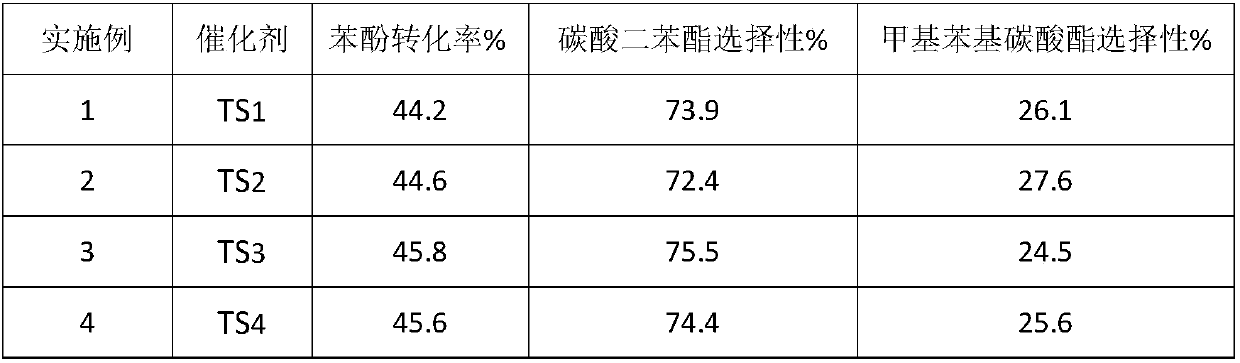

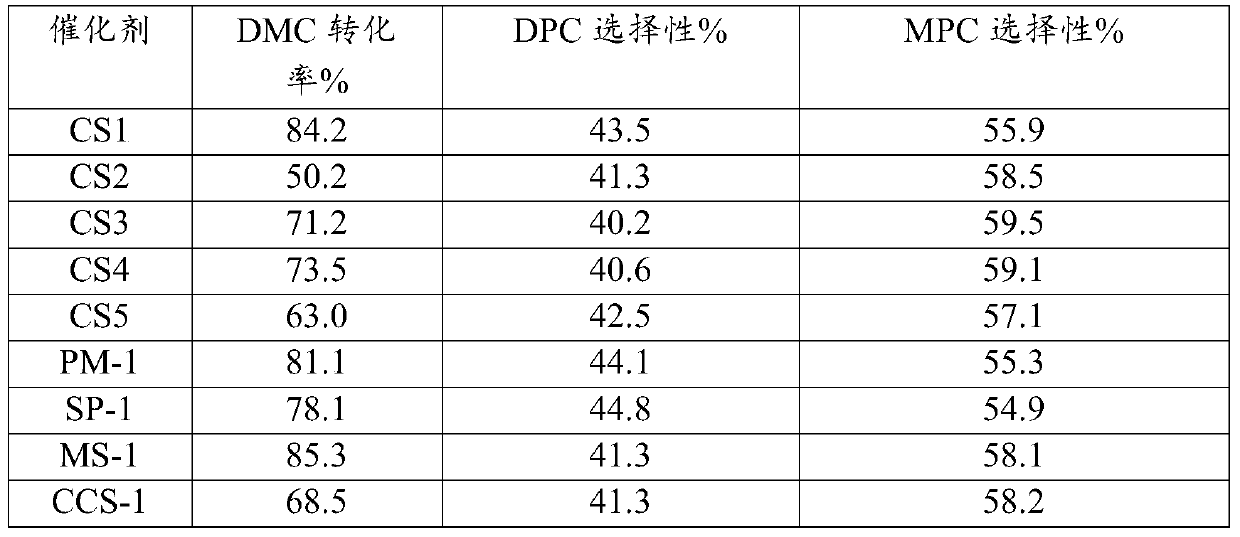

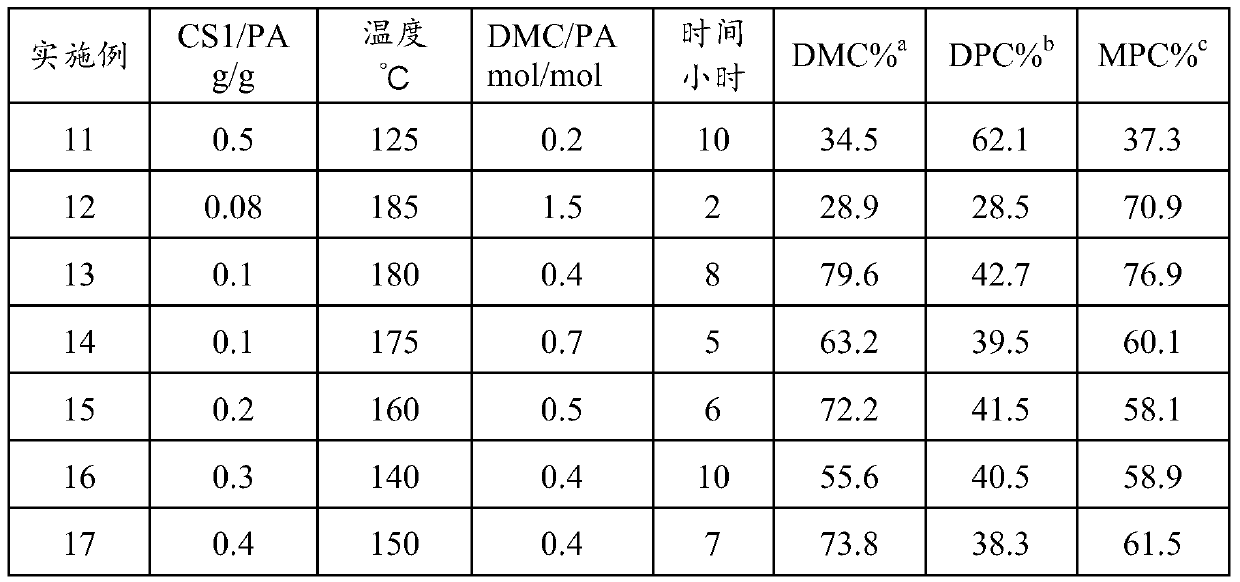

Preparation and application of monodisperse solid catalyst for preparing diphenyl carbonate through interesterification

ActiveCN109675630AHigh activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsActive componentPhenol

The invention relates to a catalyst for preparing diphenyl carbonate through interesterification of dimethyl carbonate and phenol and a preparation method of the catalyst. The problems of low activityand easy loss of heterogeneous catalysts in the prior art are mainly solved. According to the catalyst, active components are fixedly loaded onto a carrier through chemical bonds, the catalyst is a loaded monodisperse tin catalytic system catalyst, and comprises the carrier and a stannate ester group, the carrier is a substrate, and the stannate ester group is the active center. According to thetechnical scheme of the catalyst, the problem of catalyst loss in a reaction of synthesis of the diphenyl carbonate through interesterification of the phenol and the dimethyl carbonate is well solved,and the catalyst can be used for industrial production of the diphenyl carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

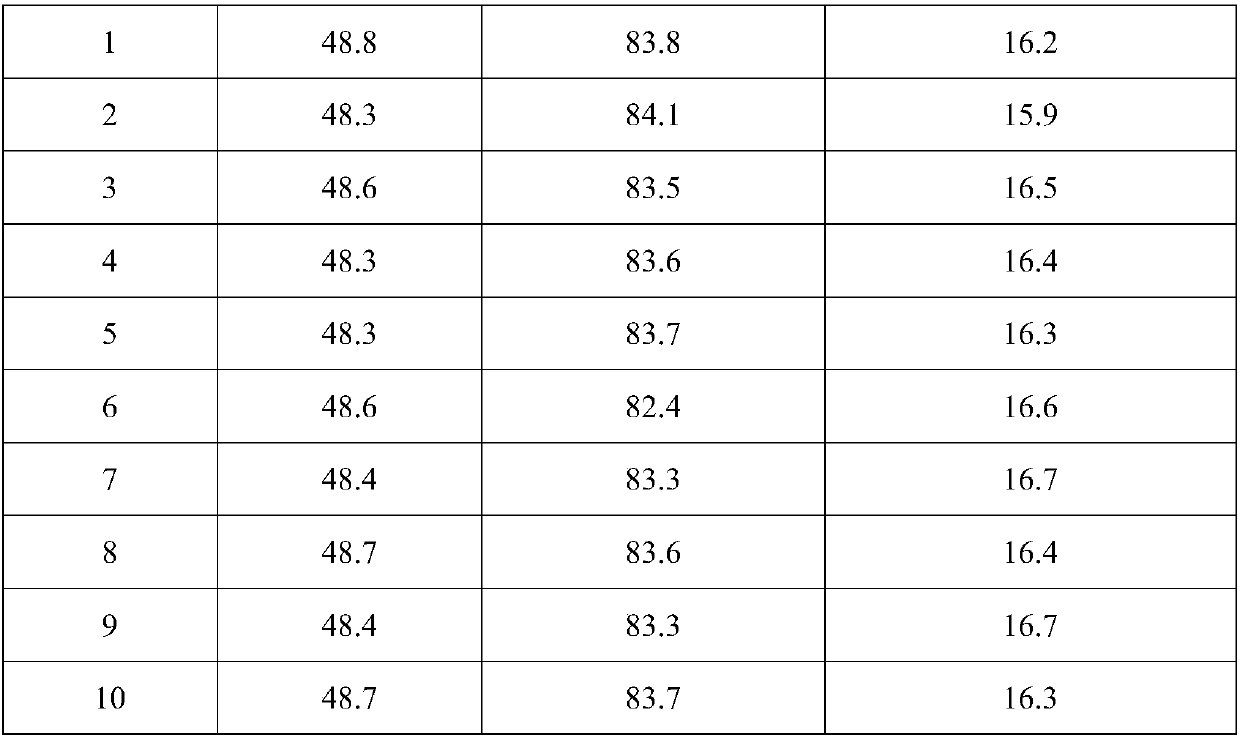

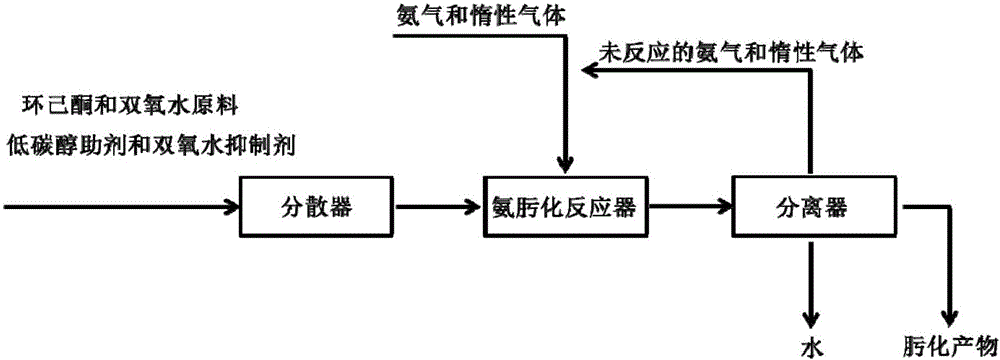

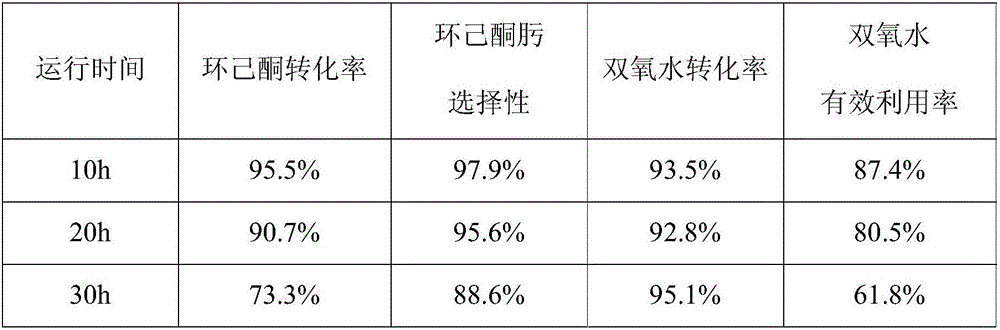

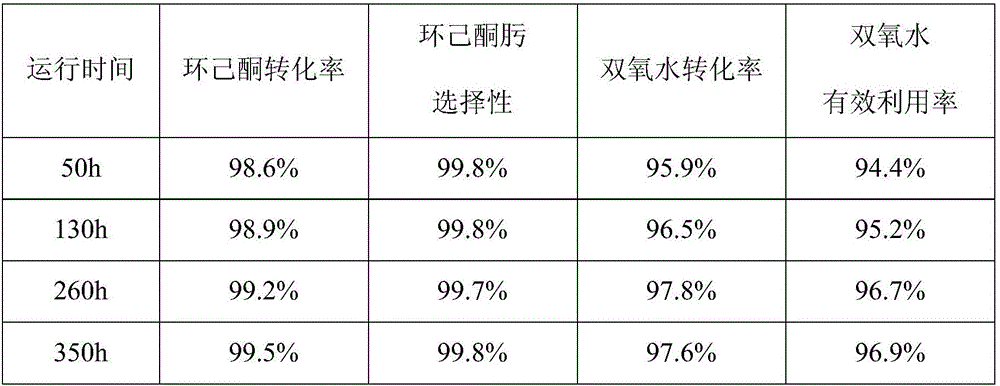

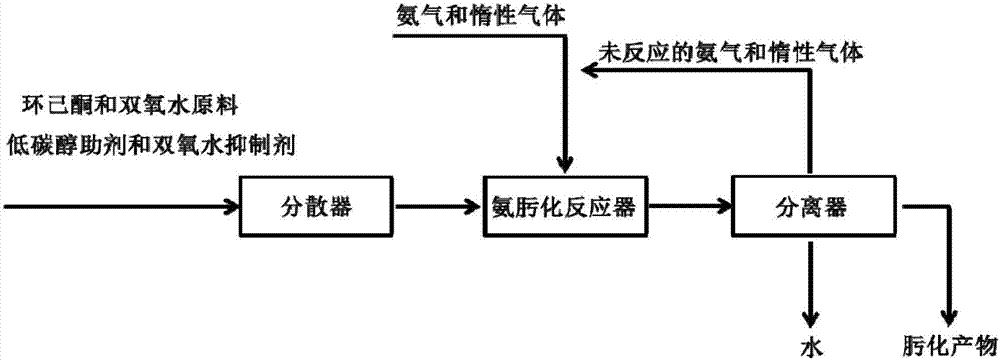

Cyclohexanone ammoximation method

ActiveCN105949083AAchieve in situ separationSolve the separation problemOximes preparationCyclohexanoneAlcohol

The invention innovatively provides a cyclohexanone ammoximation method. The method comprises steps as follows: hydrogen peroxide, an inhibitor of hydrogen peroxide, cyclohexanone and a low-carbon alcohol aid are mixed in a certain proportion to form a mixed liquid, and the mixed liquid is sent to the top of an oximation reactor to be dispersed into 1-200 mu m fine particles; mixed gas of inert gas and ammonia gas is preheated and sent into the oximation reactor to be contacted with the dispersed fine particles, and the dispersed fine particles are further gasified; the gasified fine particles and ammonia gas are placed on a titanium-containing catalyst in the oximation reactor for a cyclohexanone ammoximation reaction, the reacted mixture is separated, and a product is obtained. The problems that a catalyst in the prior art is easily inactivated, follow-up separation is difficult, membrane blocking is serious, the effective utilization rate of hydrogen peroxide is lower and the like can be effectively solved, and the cyclohexanone ammoximation method has broad and good industrial prospect.

Owner:CHINA TIANCHEN ENG +2

Micro spherical Fischer-Tropsch synthesis catalyst and preparation method thereof

ActiveCN103521238APromote decentralizationImprove catalyst activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsExothermic reactionOxide

The invention relates to a heavy hydrocarbon Fischer-Tropsch synthesis catalyst and a preparation method thereof. Since a Fischer-Tropsch synthesis reaction is a strong exothermic reaction, when a fixed bed is used, reaction heat is difficult to remove, temperature runaway is easily caused and a catalyst is easily inactivated and when a fluidized bed is used, selectivity of heavy hydrocarbon (hydrocarbons containing more than five carbon atoms) is low. By adoption fo the heavy hydrocarbon Fischer-Tropsch synthesis catalyst and the preparation method thereof, provided by the invention, all the problems in the prior art can be solved. According to the technical scheme, an iron-based fluidized bed catalyst is adopted, wherein at least one of Si and Al oxides is taken as a carrier of the catalyst and the active component of the catalyst contains a composition with the following chemical formula in atomic ratio: Fe100AaMnbCrcOx; and synthetic gas serving as raw material comes into contact with the iron-based fluidized bed catalyst in a fluidized bed to react under the conditions that the reaction pressure is 0.5-10MPa, the reaction temperature is 200-600 DEG C, reaction air speed is 100-8000 / h and ratio of H2 / CO in the raw material gas is (0.1-5.0):1, so as to generate heavy hydrocarbon. The heavy hydrocarbon Fischer-Tropsch synthesis catalyst can be applied to industrial production of fluidized bed Fischer-Tropsch synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

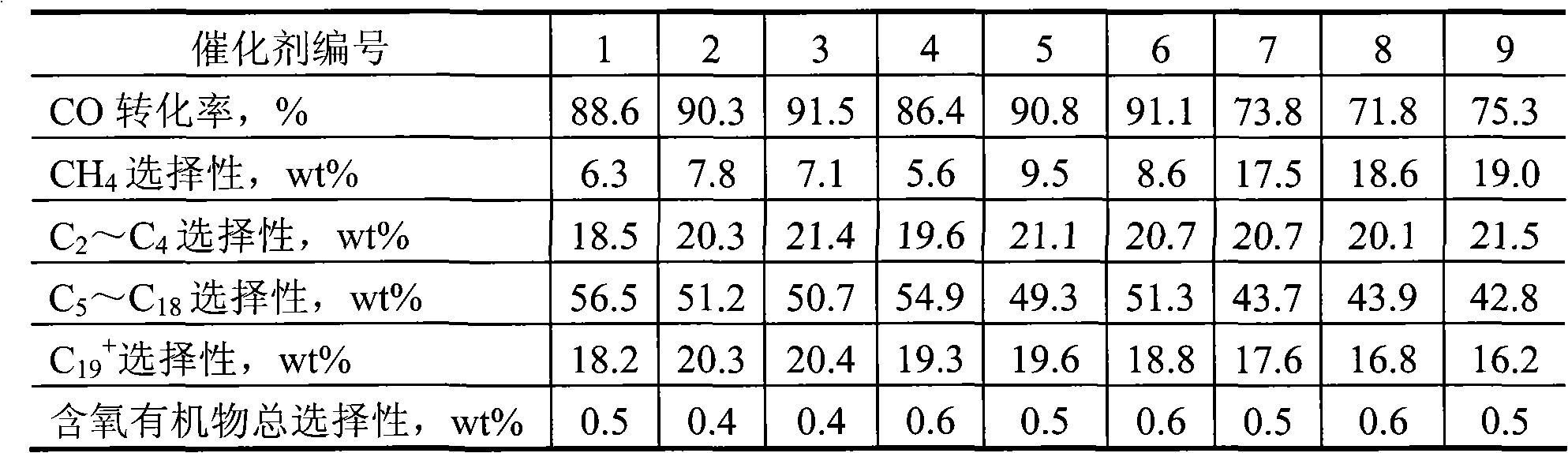

Microspheric Fischer-Tropsch synthesis catalyst and preparation method and application of microspheric Fischer-Tropsch synthesis catalyst

ActiveCN103657676AResolve volatileLow selectivityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsFixed bedExothermic reaction

The invention relates to a microspheric Fischer-Tropsch synthesis catalyst and a preparation method and application of the microspheric Fischer-Tropsch synthesis catalyst, solving the problems that as the Fischer-Tropsch synthesis reaction is the strong exothermic reaction, reaction heat is difficult to remove, temperature runaway can be easily caused, the catalyst is easy to inactivate when a fixed bed is used and heavy hydrocarbon selectivity is low when a fluidized bed is used in the prior art. According to the preparation method, at least one of oxides of Si or Al is adopted as a carrier, active components comprise the following compounds (chemical formulas are as below) according to the atomic ratio: Fe100AaBbMncZndOx, wherein A is selected from at least one of alkali metal, and B is selected from at least one of Mg and Ca; the microspheric Fischer-Tropsch synthesis catalyst can be used for industrial production of Fischer-Tropsch synthesis reaction of the fluidized bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of transition metal modified silicalite catalyst

ActiveCN107497481BResolve volatileHigh catalytic efficiencyGas treatmentMolecular sieve catalystsMetal nitrateNitrate

The invention relates to a preparation method of a transition metal modified silicon-magnesium zeolite catalyst. The preparation method comprises steps as follows: a, magnesium sulfate is added to deionized water, concentrated sulfuric acid is added, and a solution A is obtained; b, a silicon source is added to the deionized water, and a solution B is obtained; c, the solution A is slowly added to the solution B, meanwhile, a template agent is added, and a solution C is obtained; d, the solution C is stirred for 0.5 h at high speed, and obtained gel is put in a hydrothermal crystallization kettle for crystallization; e, a solution obtained after crystallization in the step d is subjected to suction filtration, a mother solution is removed, a product is dried in a drying oven at the temperature of 100 DEG C for 24 h, and raw silicon-magnesium zeolite powder is obtained; f, the raw silicon-magnesium zeolite powder is added to a metallic nitrate solution and stirred for 2 h, a co-precipitation agent is dropwise added, pH is regulated to 10, a mixture is stirred and dried in the shade, and a catalyst precursor is obtained; g, the catalyst precursor is roasted at the temperature of 500-600 DEG C. The silicon-magnesium zeolite catalyst prepared with the method has the advantages of high catalytic activity and good stability.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of method that catalytic hydrogenation prepares m-aminobenzenesulfonic acid

ActiveCN103804242BLow market priceReduce loadChemical recyclingSulfonic acid preparationFiltrationHydrogen pressure

Belonging to the field of fine chemical industry, the invention in particular relates to a method for preparation of m-aminobenzenesulfonic acid by catalytic hydrogenation. The method includes: taking sodium m-nitrobenzene sulfonate as the raw material, adding water for dissolving, boiling the mixture by activated carbon, conducting hot filtration, adjusting the pH value of the filtrate to 7.5-8.5 by a sodium hydroxide aqueous solution, employing Pt-Ru / C as a catalyst to perform hydrogenation reduction for preparation of m-aminobenzenesulfonic acid, ending the hydrogenation reduction reaction when the hydrogen pressure no longer changes, filtering out the Pt-Ru / C catalyst at the end of the reaction, firstly washing the catalyst by ethanol, then carrying out washing recycling, with the recycled catalyst being able to be applied over 50 times and still having a conversion rate and selectivity up to 99%; and subjecting the obtained filtrate to acid precipitation to pH of 2, thus obtaining a white crystal, i.e. the target product m-aminobenzenesulfonic acid. The method provided by the invention lowers the catalyst cost, improves the utilization rate of equipment, and also overcomes the problems of pollution and energy consumption in the regeneration process of the catalyst.

Owner:中国中化股份有限公司 +1

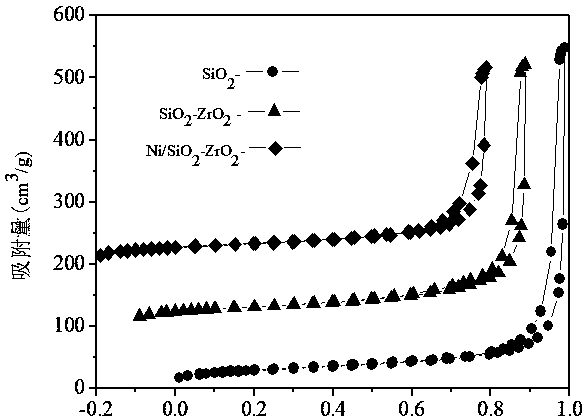

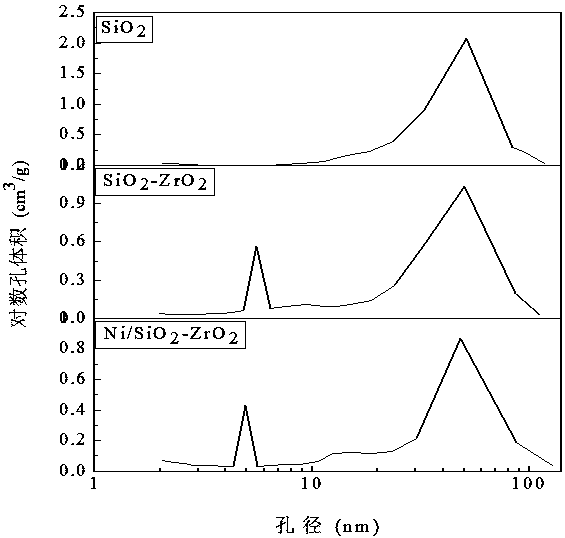

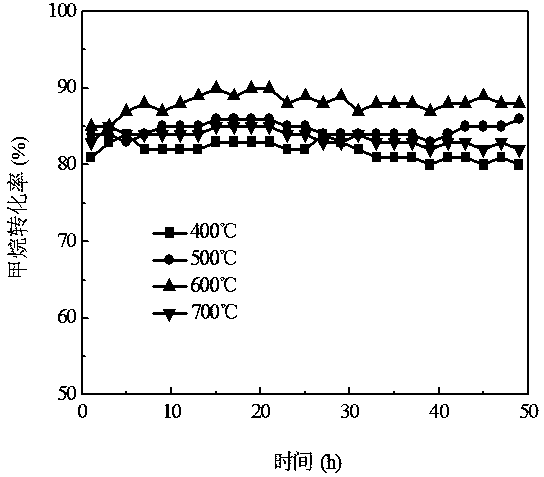

A dual mesoporous structure ni/sio for partial oxidation of methane 2 ‑zro 2 Catalyst preparation method

ActiveCN105363452BDouble mesoporous structure is obviousLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChemical industryPartial oxidation

A kind of dual mesoporous structure Ni / SiO for partial oxidation of methane 2 ‑ZrO 2 A catalyst preparation method belongs to the technical fields of natural gas chemical industry and coal chemical industry. The present invention uses an impregnation method to prepare dual mesoporous structure Ni / SiO supporting active component nickel. 2 ‑ZrO 2 The catalyst has a large specific surface area and pore volume, and a uniform pore size distribution. The catalyst has a simple preparation method, has high catalytic activity for the partial oxidation reaction of methane, and can effectively suppress catalyst deactivation caused by sintering and carbon deposition. Ni / SiO related to the present invention 2 ‑ZrO 2 Dual mesoporous materials have two sizes of mesopores. The larger pore size can meet the diffusion needs of reactants and products, and the smaller pore size can provide a place for adsorption and reaction of reactants. At the same time, the material has a narrow pore size distribution. It can be adjusted within a certain range so that it can meet the needs of different reactions, opening up a new path for the development of new industrial catalysts. The preparation method of the invention is simple, the reaction conditions are mild, and it is easy for industrial production.

Owner:清创人和生态工程技术有限公司

Preparation and application of compound catalyst for preparing diphenyl carbonate

ActiveCN109675621AGuaranteed activity and selectivityGood technical effectMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsHomogeneous catalysisTitanium

The invention relates to a catalyst for preparing diphenyl carbonate through an interesterification reaction of dimethyl carbonate and phenol and a preparation method of the catalyst. The problems oflow activity and easy loss of heterogeneous catalysts in the prior art are mainly solved. Titanium active components are confined in a nanoreactor, the catalyst is a pseudo-homogeneous heterogeneous catalyst, and comprises the nanoreactor and titanate active components. According to the technical scheme of the catalyst, the problem of catalyst loss in a reaction of synthesis of the diphenyl carbonate through interesterification of the phenol and the dimethyl carbonate is well solved, and the catalyst can be used for industrial production of the diphenyl carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch synthesized Co-based fluidized bed catalyst and preparation method thereof

ActiveCN102039133BHigh mechanical strengthReduce wear rateCatalyst activation/preparationLiquid hydrocarbon mixture productionAlkaline earth metalFluidized bed

The invention relates to a Fischer-Tropsch synthesized Co-based fluidized bed catalyst and a preparation method thereof, mainly solving the problems existing in the prior art because an Fischer-Tropsch synthesis reaction is a strong exothermic reaction which causes thermal withdrawal difficulty in a reactor, temperature runaway and easy catalyst inactivation in case of using a fixed bed, and relatively low selectivity of heavy hydrocarbon in case of using a fluidized bed. By adopting the preparation method and the technical scheme that at least one of oxides of Si or Al or a mixture of the atleast one oxide and ZrO2 is selected as a carrier, and the active constituent contains the following composition with a chemical formula in the atomic ratio of Co100AaBbOx, wherein A is selected fromat least one of alkali metal or alkaline earth metal, B is selected from at least one of Cr, Ni, Cu and Zn to be combined into a catalyst, the invention favorably solves the problems and can be used in the industrial production of the Fischer-Tropsch synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for steam reforming of biomass tar and preparation method thereof

ActiveCN107008483BExtended service lifeResolve volatilePhysical/chemical process catalystsBulk chemical productionSteam reformingCerium nitrate

The invention discloses a catalyst for steam reforming of biomass tar and a preparation method thereof. The catalyst for steam reforming of biomass tar is composed of an active component and a carrier, and the active component is Ni-NiO. The carrier is non-metal nitrogen-doped mesoporous cerium oxide (N-CeO 2 ). The preparation process is to dissolve urea, nickel nitrate, and cerium nitrate in deionized water in proportion, and then slowly air-dry at a certain temperature after stirring evenly. Biomass tar steam reforming catalyst is obtained by thermal treatment and activation in a mixture of hydrogen and nitrogen. This catalyst not only has a large specific surface area, uniform and adjustable pore size, but also shows high activity and stability in the catalytic aspect of biomass tar steam reforming. , and the preparation method is relatively simple and easy to expand.

Owner:DONGGUAN UNIV OF TECH

Microspheric Fischer-Tropsch synthesized iron and zinc catalyst and preparation method and application of microspheric Fischer-Tropsch synthesized iron and zinc

ActiveCN103657677AResolve volatileLow selectivityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsFixed bedExothermic reaction

The invention relates to a microspheric Fischer-Tropsch synthesized iron and zinc catalyst and a preparation method and application of the microspheric Fischer-Tropsch synthesized iron and zinc catalyst, solving the problems that as the Fischer-Tropsch synthesis reaction is the strong exothermic reaction, reaction heat is difficult to remove, temperature runaway can be easily caused, the catalyst is easy to inactivate when a fixed bed is used and heavy hydrocarbon selectivity is low when a fluidized bed is used in the prior art. According to the preparation method, at least one of oxides of Si or Al is adopted as a carrier, active components comprise the following compounds (chemical formulas are as below) according to the atomic ratio: Fe100AaBbZncOx, wherein A is selected from at least one of alkali metal, and B is selected from at least one of Cu or Mn; the microspheric Fischer-Tropsch synthesized iron and zinc catalyst can be used for industrial production of Fischer-Tropsch synthesis reaction of the fluidized bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of silicate composite alkali expansion agent and preparation method thereof

InactiveCN103981296BReduce pollutionMeet the requirements of additivesPre-tanning chemical treatmentProteinase activitySludge

The invention discloses a silicate compound alkali swelling agent. A preparation method comprises the following steps: adding 0.5 to 5 parts of enzyme activity stabilizer into an alkali protease liquid; adding a mixture of the enzyme activity stabilizer and the alkali protease liquid into a mixed system of a silicate and an organic amine according to the ratio of 1:1; and evenly stirring, thereby obtaining the silicate compound alkali swelling agent of which the pH is between 11.0 and 13.0, the solid content is between 5% and 10%, the enzyme activity in the liquid is between 80mu / mL and 100mu / mL and the drop-out value of the enzyme activity is less than 10% after being stored at a room temperature for 180 days. The prepared silicate compound alkali swelling agent has a good swelling effect and cannot generate sludge pollution. The adopted materials are wide in source and low in cost. The silicate compound alkali swelling agent can be prepared by the existing instruments and equipment in a leather chemical factory and is mature in process. Thus, the silicate compound alkali swelling agent is easy to popularize.

Owner:SICHUAN UNIV

Fluidized bed method for producing p-xylene by type-selective alkylation of toluene and methanol

ActiveCN103588601BLow selectivityReduce temperature riseHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical recyclingAlkyl transferGas phase

The invention relates to a fluidized bed method for producing p-xylene through shape-selective toluene and methanol alkylation, and mainly solves the problem of lower selectivity for p-xylene in the prior art. The fluidized bed method for producing the p-xylene through the shape-selective toluene and methanol alkylation comprises the steps as follows: 1), raw materials enter a reaction zone of a fluidized bed reactor after heated and are contacted with an alkylation catalyst, and a mixture flow of the p-xylene is generated; 2), the mixture flow enters a rapid gas-solid separation zone, a separated gaseous product enters a follow-up separation section, a separated catalyst enters a toluene pre-contact region, at least one part of the catalyst in the toluene pre-contact region enters a regenerator for regeneration after steam stripping by a steam stripping zone, and a regenerated catalyst is formed; and 3), the regenerated catalyst returns to the reaction zone for continuous reaction. With the adoption of the technical scheme, the problem is solved, and the method can be applied to p-xylene production.

Owner:SHANGHAI HUAYI GRP CO

Preparation method of hollow palladium catalyst microspheres

ActiveCN112934220AResolve volatileExtended service lifeOrganic compound preparationCatalyst activation/preparationCellulosePtru catalyst

The invention discloses a preparation method of hollow palladium catalyst microspheres, wherein the preparation method comprises the steps: adding ethyl cellulose into diethyl ether, uniformly stirring to form a dissolving solution, then adding ammonium carbonate, continuously stirring at a constant temperature for 30-60 min, and granulating to form particles; adding ethyl silicate into absolute diethyl ether, stirring at low temperature to form silyl ether liquid, then uniformly spraying the silyl ether liquid on the surfaces of particles, and drying at constant temperature to form a first surface film; adding ethyl silicate and palladium acetate into diethyl ether, uniformly stirring to form a mixed solution, then uniformly spraying the mixed solution on the first surface film, and drying at constant temperature to obtain a second surface film; uniformly spraying the silyl ether liquid on the second surface film, and drying at constant temperature to obtain a third surface film; and then putting the particles with the third surface film into a reaction kettle, standing for 2-5 hours to obtain a prefabricated catalyst, and carrying out reduction reaction to obtain the hollow palladium catalyst. The mesoporous structure of a silica layer can effectively prevent macromolecules from entering, contact between hydrogen molecules and palladium particles is not affected, and a good catalytic effect is achieved.

Owner:浙江工业大学上虞研究院有限公司

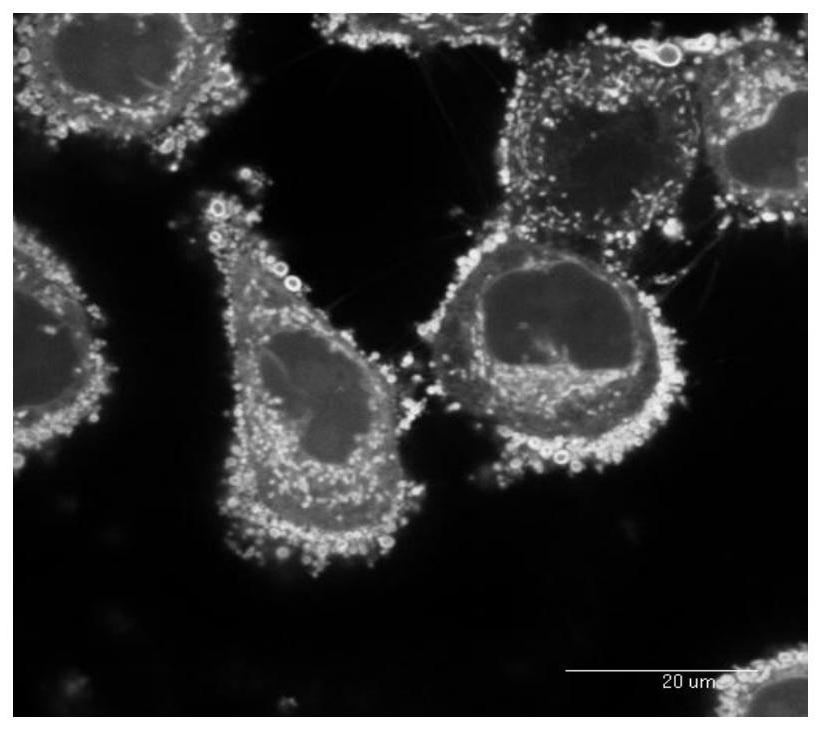

A method for in situ analysis of intracellular protein complexes and its application

ActiveCN112083081BResolve volatileSolve the problem of difficult in situ analysisComponent separationProtein-protein complexDrug target

The invention involves an in -site analysis method and application of an intracellular protein complex.In this method, use the parcel crosslinker carrier to incubate with the cells, use intracellular swallowing, and transport the linked agent to a specific part of the cell, and release the chemical cross -linked agentEssenceSubsequently, the protein extraction method based on ionic liquid was used to extract protein and its complexes, and further combined with mass spectrometry technology to analyze the in situ analysis of intracellular protein complexes.This method is of great significance for resolving the dynamic changes in the time and space of the cells in the cells, understanding the process of life, understanding the process of life, revealing the disease mechanism, screening biomarkers, and finding drug targets.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Titanium dioxide microspheres@all silicon silica-1 molecular sieve core-shell catalyst, preparation method and application

ActiveCN106563488BGuaranteed activityGuaranteed selectivityMolecular sieve catalystsPreparation from organic carbonatesMolecular sieveMicrosphere

The invention relates to a titanium dioxide microsphere@all-silicon silica-1 molecular sieve core-shell-structured catalyst, and a preparation method and application thereof. The nuclear phase of the catalyst is a titanium dioxide microsphere, and the shell layer of the catalyst is an all-silicon silica-1 molecular sieve; and the catalyst is applicable to industrial production for diphenyl carbonate through transesterification of dimethyl carbonate and phenyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of cyclohexanone ammoximation method

ActiveCN105949083BAchieve in situ separationSolve the separation problemOximes preparationCyclohexanoneAlcohol

The invention innovatively provides a cyclohexanone ammoximation method. The method comprises steps as follows: hydrogen peroxide, an inhibitor of hydrogen peroxide, cyclohexanone and a low-carbon alcohol aid are mixed in a certain proportion to form a mixed liquid, and the mixed liquid is sent to the top of an oximation reactor to be dispersed into 1-200 mu m fine particles; mixed gas of inert gas and ammonia gas is preheated and sent into the oximation reactor to be contacted with the dispersed fine particles, and the dispersed fine particles are further gasified; the gasified fine particles and ammonia gas are placed on a titanium-containing catalyst in the oximation reactor for a cyclohexanone ammoximation reaction, the reacted mixture is separated, and a product is obtained. The problems that a catalyst in the prior art is easily inactivated, follow-up separation is difficult, membrane blocking is serious, the effective utilization rate of hydrogen peroxide is lower and the like can be effectively solved, and the cyclohexanone ammoximation method has broad and good industrial prospect.

Owner:CHINA TIANCHEN ENG +2

Fluidized bed Tropsch synthesis method for heavy hydrocarbons

ActiveCN102041020BHigh selectivityFast coolingLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalSynthesis methods

The invention relates to a Tropsch synthesis method for heavy hydrocarbons, which mainly solves the problems that the reaction heat dissipation is difficult, temperature runaway is easily caused and the catalyst is easily inactivated when a fixed bed is used and the selectivity of the heavy hydrocarbons is low when a fluidized bed is used in the prior art because the Tropsch synthesis reaction is strong heat generating reaction. Synthesis gas is used as a raw material; under the conditions that the reaction pressure is 0.5 to 10MPa, the reaction temperature is 200 to 600 DEG C, the reaction space velocity is 100 to 8,000 per hour and the H2 / CO molar ratio of the raw material gas is 0.1-5.0: 1, the raw material is contacted with a cobalt-based fluidized bed catalyst in the fluidized bed and reacted to generate the heavy hydrocarbons, wherein the heavy hydrocarbons are hydrocarbons of over C5; and in the cobalt-based fluidized bed catalyst, at least one of oxides of Si and Al or mixture of Si or Al and ZrO2 is selected as a carrier, and the active ingredient contains the following compound with chemical formula in an atomic ratio: Co100AaBbOx, wherein in the formula, A is selected from at least one of alkali metals or alkaline earth metals, and B is selected from at least one of Cr, Ni, Cu and Zn. According to the technical scheme, the problems are well solved, and the method can be used in the industrial production of fluidized bed Tropsch synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com