Catalyst for directly preparing light hydrocarbon through synthesis gas and preparation method of catalyst

A technology for synthesis gas and light hydrocarbons, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problem that the selectivity of light hydrocarbons and low-carbon olefins is not high enough , the product is not concentrated enough, easy to overheat and other problems, to achieve the best catalytic effect, improve activity, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

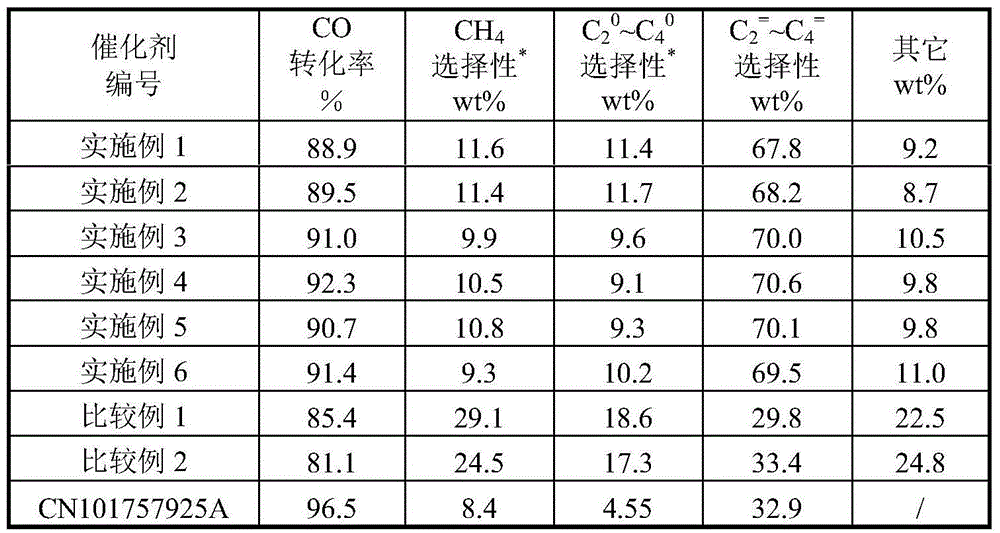

Examples

Embodiment 1

[0059] Take 589.9 grams of ferric nitrate, add 1000 grams of water to dissolve, and obtain material I, take 0.4 grams of lanthanum nitrate and add 10 grams of water to dissolve, and obtain material II, take 25.56 grams of 50% manganese nitrate and 21.00 grams of cobalt nitrate in the same container, add 200 grams of water , stirring and dissolving to obtain material III.

[0060] Materials I, II, and III are mixed, and 312.5 grams of 40% (weight) aluminum sol materials are added under stirring, then 50 g of a solution containing 0.1 gram of KOH is added, and the pH value of the above-mentioned slurry is adjusted with ammonia water to make the pH of the mixed slurry = 6.0, after sufficient stirring, the prepared slurry is carried out in a spray dryer according to the usual method to form microspheres, and finally the internal diameter is 89 mm, and the length is 1700 mm (φ89 × 1700 mm) in a rotary roaster. Calcined at 500°C for 2.0 hours, the composition of the prepared catalys...

Embodiment 2

[0063] Take 589.8 grams of ferric nitrate, add 1000 g of water to dissolve, and obtain material I, take 0.4 g of lanthanum nitrate and add 10 g of water to dissolve, obtain material II, take 25.60 g of 50% manganese nitrate and 21.00 g of cobalt nitrate in the same container, add 200 g of water , stirring and dissolving to obtain material III.

[0064] Materials I, II, and III are mixed, and 312.5 grams of 40% (weight) aluminum sol materials are added under stirring, and then 0.1 gram of KOH and 0.06 gram of RuCl are added. 3 50g of the solution, adjust the pH value of the above slurry with ammonia water to make the pH=6.0 of the mixed slurry, after fully stirring, the prepared slurry is carried out into microspheres in a spray dryer according to the usual method, and finally the inner diameter is 89 mm, length is 1700 mm (φ89 * 1700 mm) rotary roaster at 500 ℃ roasting 2.0 hours, the catalyst composition of making is:

[0065] 50 wt% Fe 100 mn 0.1 co 5.0 K 0.1 La 0.1 Ru...

Embodiment 3

[0067] Take 589.8 grams of ferric nitrate, add 1000 g of water to dissolve, and obtain material I, take 0.4 g of lanthanum nitrate and add 10 g of water to dissolve, obtain material II, take 25.60 g of 50% manganese nitrate and 21.00 g of cobalt nitrate in the same container, add 200 g of water , stirring and dissolving to obtain material III.

[0068] Materials I, II, and III are mixed, and 312.5 grams of 40% (weight) aluminum sol materials are added under stirring, and then 0.1 gram of KOH and 0.04 gram of PdCl are added. 2 and 0.06 g RuCl 3 50g of the solution, adjust the pH value of the above-mentioned slurry with ammonia water so that the pH=6.0 of the mixed slurry, obtain the slurry after fully stirring, carry out the microsphere molding of the prepared slurry in a spray drier according to the usual method, Inner diameter is 89 millimeters at last, and length is 2.0 hours in 500 ℃ of roastings in the rotary roaster of 1700 millimeters (φ 89 * 1700 millimeters), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com