A dual mesoporous structure ni/sio for partial oxidation of methane 2 ‑zro 2 Catalyst preparation method

An oxidation reaction and double mesoporous technology, which is applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. Mesoporous structure with complex process, uniform pore size distribution and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

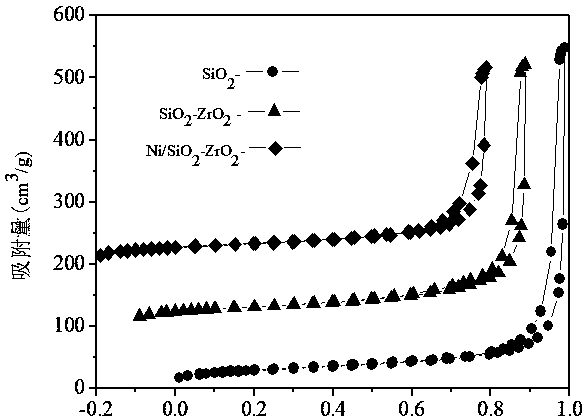

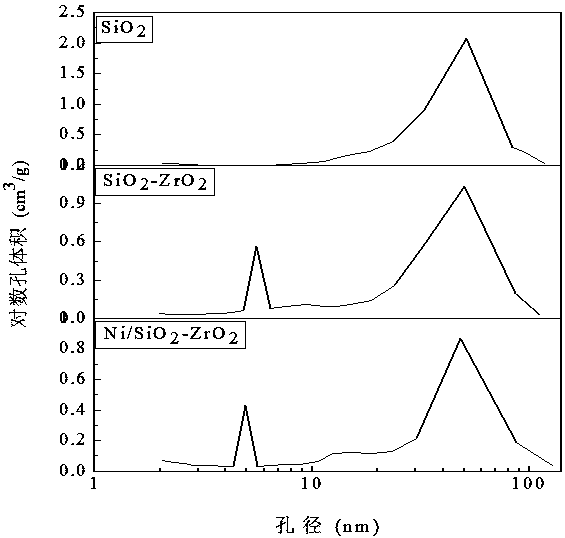

[0025] 1) Add 0.71g of Zr(NO 3 ) 2 .5H 2 O was dissolved in 7.4 mL of deionized water and stirred for 0.5 h;

[0026] 2) Use the equal volume impregnation method to impregnate the solution obtained in step 1) in 5.0 g of SiO with a larger pore size 2 , baked at 600°C for 2h;

[0027] 3) Add 0.78g of Ni (NO 3 ) 2 .6H 2 O was dissolved in 4.2 mL of deionized water and stirred for 0.5 h;

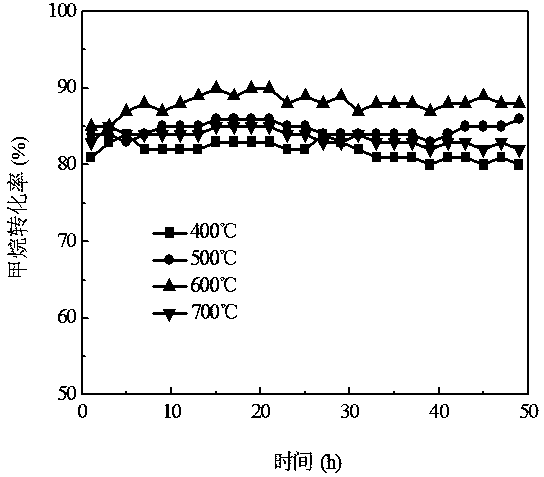

[0028] 4) Also use the same volume impregnation method to impregnate 3.0 g of the double mesoporous SiO obtained in step 2) with the solution obtained in 3) 2 -ZrO 2 , drying at 110°C for 12h, calcination at 400°C, 500°C, 600°C, 700°C for 4h;

[0029] 5) The prepared catalyst was crushed to 40-60 mesh, under normal pressure, the reaction temperature was 600 °C, and the space velocity was 5×10 4 mL·g -1 h -1 Under these conditions, the conversion rate of methane is 80-90%.

Embodiment approach 2

[0031] 1) Add 0.71g of Zr(NO 3 ) 2 .5H 2 O and 0.78g Ni (NO 3 ) 2 .6H 2 O was simultaneously dissolved in 7.4 mL of deionized water and stirred for 0.5 h;

[0032] 2) Use the equal volume impregnation method to impregnate the solution obtained in step 1) in 5.0 g of SiO with a larger pore size 2, dried at 110°C for 12h, and calcined at 600°C for 4h;

[0033] 3) The prepared catalyst was crushed to 40-60 mesh, under normal pressure, the reaction temperature was 600 °C, and the space velocity was 5×10 4

[0034] mL·g -1 h -1 Under these conditions, the methane conversion rate was 83%.

Embodiment approach 3

[0036] 1) Dissolve 0.44g ZrO with deionized water 2 The sol was diluted to 7.5mL and stirred for 0.5h;

[0037] 2) Use the equal volume impregnation method to impregnate the solution obtained in step 1) in 5.0 g of SiO with a larger pore size 2 , baked at 700°C for 4h;

[0038] 3) Add 0.78g of Ni (NO 3 ) 2 .6H 2 O was dissolved in 4.2mL of ethanol and stirred for 0.5h;

[0039] 4) Also use the same volume impregnation method to impregnate the solution obtained in 3) into 3 g of the double mesoporous SiO obtained in step 2). 2 -ZrO 2 , dried in vacuum at 80°C for 12h, and fired at 600°C for 4h;

[0040] 5) The prepared catalyst was crushed to 40-60 mesh, under normal pressure, the reaction temperature was 600 °C, and the space velocity was 5×10 4 mL·g -1 h -1 Under these conditions, the conversion rate of methane is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com